HD Grade Graphite Electrode for Sale for Foundry Used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

We has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line. Our annual capacity is 60,0000tons.

2.Main Features of the Graphite Electrode

(1) Direct manufacturer, office based on Beijing.

(2) Competitive price with prior quality

(3) High density with low resistivity

(4) High carbon content

(5) RP HD HP UHP Grade for your reference

3.Graphite Electrode Images

Packaging: Wooden Pallets, well packaged.

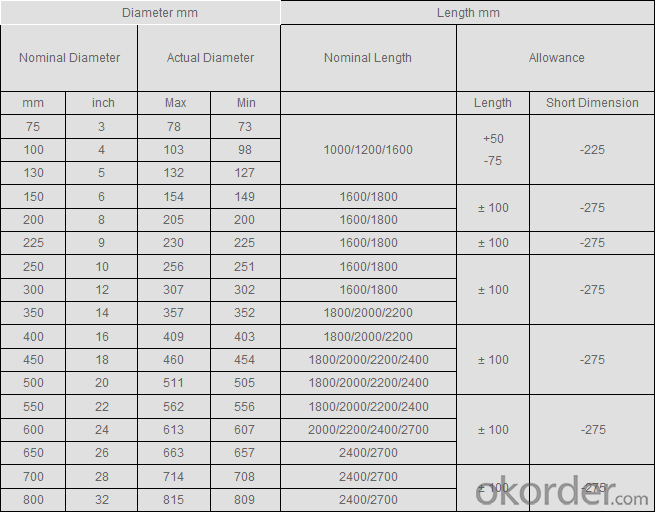

4.Graphite Electrode Specification

5.FAQ

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance. We welcome you to visit our mill.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

20% deposit, balance against the BL copy。

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit.

- Q: Classification, uses and manufacturers of graphite electrodes

- Graphite as electrode(1) the processing speed is faster: normally, the mechanical processing speed of graphite can be 2~5 times faster than copper, while the discharge processing speed is 2~3 times faster than copper;More material is not easily deformed: obvious advantages in the processing of thin electrodes; copper softening point at about 1000 degrees, easily deformed by heat; graphite sublimation temperature is 3650 degrees; the thermal expansion coefficient of copper is only 1/30.(2) lighter weight: the density of graphite is only 1/5 of copper. When large electrode is used for discharge machining, it can effectively reduce the burden of machine tools (EDM). It is more suitable for large-scale die applications.

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The hardfacing of wear-resistant alloy powder block is mostly made by carbon arc surfacing. General selection of graphite or carbon arc surfacing carbon rod and plate electrodes, which has good conductivity, high melting point;

- Q: Why graphite can be used as conductive material?

- Graphite used in the electrical industry requires a high degree of particle size and grade. Such as alkaline batteries and some special electric carbon products, requiring graphite particle size control within the scope of the project, grade above, harmful impurities are required in the following. The graphite used in a picture tube for television is required below. As a wear-resistant and lubricating material, graphite is often used as a lubricant in the mechanical industry.

- Q: What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- The first answer to the equation above is quite right, or it may be that a layer of calcium carbonate is attached to the surface of the electrode, which prevents the electrode from conducting and leads to an increase in resistance

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: The reason why graphite is used as electrode

- Graphite has good thermal stabilityThe softening point of copper in 1000 degrees, easily deformed by heat, the melting point of graphite is 3850 + 50 DEG C, the boiling point of 4250 DEG C, even after the ultra high temperature arc ignition, the weight loss is very small, the thermal expansion coefficient is small. The strength of graphite increases with the increase of temperature, and the strength of graphite is doubled at 2000 degrees centigrade. In comparison, the thermal expansion coefficient of graphite material is only 1/30 of copper material.

- Q: How long is the graphite electrode machining cycle?

- Industrial graphite is hard and brittle, and the tool is worn more seriously during machining. It is generally recommended to use carbide or diamond coated cutting tools. When the graphite is rough, the cutter can be directly worked on the workpiece. When it is finished, it is necessary to use light knife to walk quickly to avoid the occurrence of chipping and chipping

- Q: What kind of asphalt is better for natural graphite coating?

- Graphite anode is mainly made of petroleum coke as raw material and coal pitch as binder. It is made by calcination, batching, kneading, pressing, roasting, impregnating, graphitization and machining. Conductive anode used for electrolysis equipment in electrochemical industry. Including: (1) anode plate for various chemical industries. (2) all kinds of anode rods.

- Q: What kinds of carbon are there?

- The carbon block can be divided into blast furnace carbon block, aluminum carbon block and electric furnace block. Carbon products can be divided into carbon products, graphite products, carbon fibers and graphite fibers according to the depth of processing. Carbon products can be divided into graphite products, carbon products, carbon fibers and special graphite products according to the raw materials and the production process. Carbon products according to their ash content, and can be divided into multi gray products and less ash products (including ash below l%).

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

HD Grade Graphite Electrode for Sale for Foundry Used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches