4.5in Premium Casing: 5.21-15.88mm WT, J55/K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

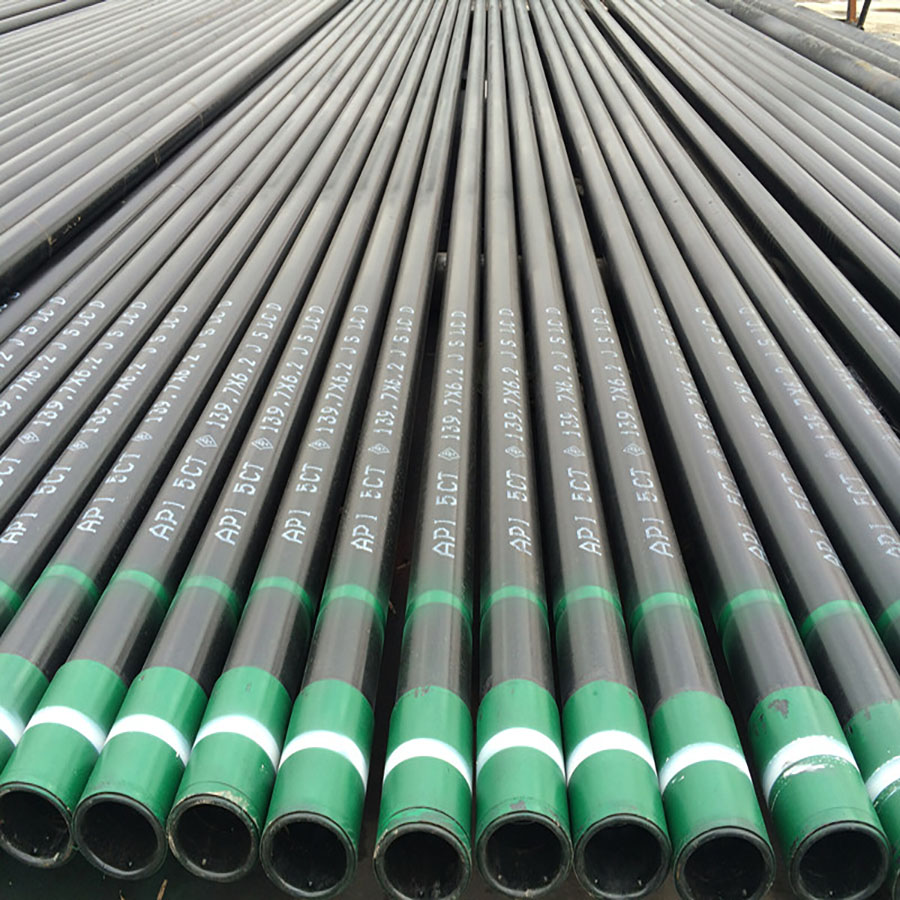

Petroleum Casing Product Information

1. Product Overview

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

2. Technical Specifications

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

3. Chemical Composition (Example: L80 Grade)

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

4. Application Scenarios

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

5. Production Process

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

6. Case Studies

Middle East Oilfield Project:

Delivered 13-3/8" P110 casing for 4,500-meter well depth, collapse resistance 120 MPa.

7" TP140TT casing supports 30-stage fracturing, boosting single-well output by 25%.

Key Features

J55/P110 Casing: High-strength, corrosion-resistant, compliant with API 5CT.

TP140TT Grade: Optimized for shale gas fracturing with extreme pressure resistance.

Deepwater Compliance: Certified for 3,000-meter offshore operations.

- Q: How are steel pipes used in desalination plants?

- Steel pipes are used in desalination plants to transport and distribute the seawater and treated water throughout the facility. They are durable and resistant to corrosion, ensuring the efficient and reliable movement of water in the desalination process.

- Q: What is the difference between steel pipe and fiberglass pipe?

- Steel pipe and fiberglass pipe differ in terms of their material composition, flexibility, resistance to corrosion, and cost. Steel pipe is made of an alloy of iron and carbon, known for its strength and durability, making it a popular choice for plumbing, construction, and industrial projects. In contrast, fiberglass pipe is composed of glass fibers embedded in a resin matrix, resulting in a lightweight and corrosion-resistant material suitable for applications requiring chemical resistance. Another contrasting factor between steel pipe and fiberglass pipe is their level of flexibility. Steel pipe is rigid and stiff, while fiberglass pipe offers greater flexibility, allowing it to bend and conform to different shapes and contours. This flexibility makes fiberglass pipe easier to install in tight spaces or areas with complex geometries. Corrosion resistance is another significant difference between the two materials. Steel pipe is susceptible to corrosion, particularly in environments with high moisture or chemical exposure. To counteract this, steel pipes are often coated or lined with corrosion-resistant materials. In contrast, fiberglass pipe is inherently resistant to corrosion due to its construction, making it a preferred choice for applications in saltwater environments or chemical processing plants. Cost is yet another factor that sets steel pipe and fiberglass pipe apart. Generally, steel pipe is more affordable than fiberglass pipe, especially for smaller diameter pipes. However, as the diameter and pressure rating increase, the cost of steel pipe can exceed that of fiberglass pipe. Additionally, fiberglass pipe requires less maintenance and has a longer lifespan, which can offset the initial cost difference over time. In conclusion, the differences between steel pipe and fiberglass pipe can be summarized in terms of their material composition, flexibility, corrosion resistance, and cost. The choice between these two types of pipes depends on various project requirements, including the application, environment, budget, and expected lifespan.

- Q: What is the difference between Schedule 40 and Schedule 80 steel pipes?

- The main difference between Schedule 40 and Schedule 80 steel pipes is their wall thickness. Schedule 80 pipes have a thicker wall compared to Schedule 40 pipes, making them more suitable for high-pressure applications and heavy-duty industrial use.

- Q: Can steel pipes be used for pharmaceutical manufacturing?

- Yes, steel pipes can be used for pharmaceutical manufacturing. Steel pipes are commonly used in various industries, including pharmaceutical manufacturing, due to their durability, strength, and resistance to corrosion. In pharmaceutical manufacturing, steel pipes are primarily used for fluid transportation, such as the transfer of chemicals, solvents, and other raw materials. They are also used for the distribution of process water, steam, and other utilities. Stainless steel pipes are particularly preferred in pharmaceutical manufacturing as they are highly resistant to corrosion and can withstand high temperatures and pressures. Moreover, stainless steel pipes have smooth surfaces, which prevent the accumulation of particles and facilitate easy cleaning and sterilization, essential requirements in pharmaceutical production. Overall, steel pipes are a reliable and suitable option for pharmaceutical manufacturing due to their robustness, resistance to corrosion, and ability to meet the stringent cleanliness and hygiene standards of the industry.

- Q: Are steel pipes suitable for offshore drilling platforms?

- Steel pipes have been widely used in offshore drilling platforms because of their strength, durability, and resistance to corrosion. These platforms operate in harsh marine environments, where they are exposed to saltwater, extreme pressure, and temperature changes. Steel pipes are capable of enduring these conditions and serving as a reliable and long-lasting solution for transporting fluids, such as oil and gas, from the seabed to the surface. Moreover, the ability to weld steel pipes together facilitates their easy installation and maintenance on offshore drilling platforms. In conclusion, steel pipes have proven to be an appropriate choice for offshore drilling platforms due to their robustness and ability to withstand the challenging conditions of the marine environment.

- Q: Are steel pipes suitable for underground installations in areas with high moisture content?

- Yes, steel pipes are suitable for underground installations in areas with high moisture content. Steel pipes are known for their durability and resistance to corrosion, which makes them ideal for withstanding moisture and underground conditions. Additionally, steel pipes can be coated or lined with protective materials to further enhance their resistance to moisture, ensuring their long-term performance and reliability in such environments.

- Q: What are the advantages of using steel pipes in construction?

- There are several advantages of using steel pipes in construction. Firstly, steel pipes are highly durable and have a long lifespan, making them ideal for long-term projects. Secondly, steel pipes have a high strength-to-weight ratio, meaning they can support heavy loads without being bulky or cumbersome. Additionally, steel pipes are resistant to corrosion, which ensures their longevity and reduces maintenance costs. Moreover, steel pipes are adaptable and can be easily fabricated and customized to fit specific project requirements. Lastly, steel pipes are eco-friendly as they can be recycled, reducing waste and promoting sustainability in construction.

- Q: What are the factors to consider when selecting the right steel pipe for a specific application?

- When selecting the right steel pipe for a specific application, there are several factors that need to be considered. These factors include: 1. Material compatibility: It is important to ensure that the steel pipe is compatible with the material it will be transporting or containing. Different materials may require specific types of steel pipes to avoid corrosion or contamination. 2. Pressure and temperature requirements: The pressure and temperature conditions that the steel pipe will be exposed to must be taken into account. This will determine the required thickness and strength of the pipe to ensure it can withstand the desired operating conditions. 3. Size and dimensions: The size and dimensions of the steel pipe should be chosen based on the flow rate, volume, and space available for installation. It is crucial to select a pipe with the appropriate diameter and wall thickness to prevent any flow restrictions or leakage. 4. Environmental conditions: The environment in which the steel pipe will be installed should be considered. Factors such as exposure to moisture, chemicals, or extreme temperatures may require the use of specific coatings or materials to enhance the pipe's durability and longevity. 5. Cost considerations: The cost of the steel pipe and its installation should be taken into account. It is essential to strike a balance between the desired quality and the available budget to ensure the most cost-effective solution. 6. Regulatory compliance: Depending on the application, there may be specific industry regulations or standards that need to be followed. It is important to choose a steel pipe that meets these requirements to ensure compliance and avoid any legal or safety issues. 7. Maintenance and lifespan: The maintenance requirements and expected lifespan of the steel pipe should also be considered. Some applications may require regular inspections or replacements, while others may require a more durable and long-lasting pipe. By carefully considering these factors, one can select the right steel pipe for a specific application that meets the desired performance, durability, and safety requirements.

- Q: Can steel pipes be used for oil transportation?

- Yes, steel pipes can be used for oil transportation. Steel pipes are commonly used in the oil and gas industry for the transportation of crude oil, petroleum products, and natural gas. They are preferred due to their strength, durability, and resistance to corrosion. Steel pipes are capable of withstanding high-pressure environments and can be used for both onshore and offshore oil transportation. Additionally, steel pipes can be welded together to form long pipelines, making them a cost-effective solution for transporting oil over long distances. Overall, steel pipes are a reliable and efficient choice for oil transportation.

- Q: Galvanized steel pipe in addition to good rust resistance, what are the advantages?

- It has the characteristics of corrosion resistance and wear resistance, so it can be used longer;

Send your message to us

4.5in Premium Casing: 5.21-15.88mm WT, J55/K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords