3mm sintra pvc foam board for decoration

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

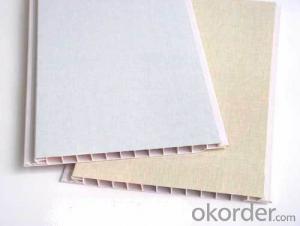

PVC Foam Board

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer

lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

- Q: Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You said the ground is not cement road level, there are a lot of holes, I do not know you are not the ground is the sand from the like, if there is a sand from the proposed you do not do cement self-leveling so that the quality of your floor There is no guarantee that the ground is not cement road Ping suggested that you do not do cement self-leveling and do not say how the effect of the cost is too high, the cement self-leveling to find someone to do the price of 15-25 yuan per square meter, and cement self-leveling Each can only do 2-4MM meters, that is to say that you want to make a good effect at least have to do 2 to 3 times, so the cost is too high, I do many years of PVC flooring, it is recommended that you shop The ground before the first to find a good way to find the mud on the ground so that you will be less to a lot of cost and the effect of the bottom out of the floor will be much better

- Q: Cottage ceiling with a pvc board can hang ceiling fan?

- No, you must open the hanging to the original structure

- Q: How to buy pvc floor?

- Choose PVC floor method steps: 1, the first is to smell, with the nose sniff about whether the smell of the floor, the quality of qualified PVC floor is no smell. And those low quality floors contain formaldehyde. 2, you can use dirty soles in the floor surface scribble, the floor left behind the dirty traces, scrub with a clean cloth, if you can not clean or clean is not complete, indicating poor stain resistance of the floor. 3, you can use your fingertips, knives or some other sharp objects in the floor surface to pull the floor to test the wear resistance of the floor, the line marks are not obvious that the floor wear resistance is poor. 4, you can use the knife to cut the floor to test the stability of the floor, if the floor is easy to be cut, it shows that the floor is not glass fiber layer, so poor stability of the floor. 5, the test floor of the acid and alkali resistance, you can drop on the floor surface of alcohol, oil, a small amount of hydrochloric acid, one day after the observation of the surface of the floor there is a clear phenomenon of aging, and some on the floor that poor acid and alkali resistance. 6, test the antibacterial properties of PVC floor, will be easy to mildew items, such as bread and the like, on the floor surface, and the floor placed in the shade of the place, about two days after the observation of whether the surface of the fungus signs of growth, , Indicating that the floor is not antibacterial or antibacterial is very poor.

- Q: PVC board, ABS board, KT board What is the difference between ~ ~ What are the purposes?

- PP Polypropylene PVC PVC EPS polystyrene ABS acrylonitrile / butadiene / styrene copolymer PC Polycarbonate PE polyethylene KT board is a light decorative plate, the actual is the two sides affixed with smooth paper foam board, generally used for display panels or as a temporary structure of the partition. KT board can be used for display board production, screen printing, etc., with KT board produced by the beautiful display panels, convenient and light, affordable. (But according to multi-feedback: KT board like a bubble, with a long time will be variant, the proposed use of organic board) KT board color: red, white, yellow, green, gray, blue, black. Two kinds of KD board: one is "enhanced anti-foaming KD board", flatness is good, hardness is strong. Applicable to advertising display, especially for large-scale pictorial inkjet produced a variety of board, he is the best cold plate KD plate. The second is the "economic anti-blister KD board", mainly for the back of the frame, screen printing and silk screen after the POP advertising production. It is the best KD plate to bite the market.

- Q: What is the difference between an integrated ceiling and a PVC ceiling?

- First, the integrated ceiling: HUV metal plate and the combination of electrical appliances. Sub-board module, heating module, lighting module, ventilation module. With the installation is simple, flexible layout, easy maintenance, a bathroom, kitchen ceiling of the mainstream. Today, with the growing development of the ceiling industry, balcony ceiling, restaurant ceiling, living room ceiling, aisle and so on are gradually becoming the mainstream of home improvement. In order to change the monotonous lack of ceiling color, integrated art ceilings are becoming the market trendy. Second, PVC gusset ceiling: the PVC resin as the base material, adding a certain amount of anti-aging agent, modifier and other additives, by mixing, calendering, vacuum blister and other technology made. This PVC gusset ceiling is particularly suitable for kitchen, bathroom ceiling decoration, with a light weight, moisture, heat insulation, not easy to burn, no dust, easy to clean, can be painted, easy to install, low prices. PVC buckle ceiling pattern more varieties, to choose from the varieties are: milky white, beige, lake blue, etc .; patterns are: Epiphyllum, flat peach, Xiong Zhu, Yunlong, grid flowers, parquet and so on. May require the production or distribution unit to produce its inspection report, and should pay special attention to whether the oxygen index is qualified, it must be greater than 30, is conducive to fire. And then according to the installation of the place and personal hobbies and environmental coordination and other factors, to select their own room decorated with decorative patterns.

- Q: I use the PVC wall to do the backdrop, there are three square, one centimeter thick PVC board how to fix to the wall, is the use of glue or nails or other methods, with glue what is the glue. It is best to get their own home to the point of advice Thank you

- Fixed a lot of ways to use plastic bolts with plastic bolts ??? The most easy way to fight a few holes on the wall of a few holes with plastic plastic nail fixed nail surface decorated with a very beautiful hat

- Q: Wood board and PVC board with what glue combination

- Universal glue full coating, thin coating, pressure paste. Or glass paste point paste.

- Q: Aluminum buckle plate and PVC gusset which is better

- PVC gussets: PVC gusset plate is also we often see the plastic plate, PVC gusset plate light quality, waterproof, moisture, heat insulation, not easy to burn, no dust, easy to clean, but also suitable for kitchen, bathroom ceiling decoration. But compared to metal ceiling, PVC ceiling appears to be inferior. PVC buckle advantages: 1, PVC buckle ceiling pattern more varieties, to choose from the varieties are: milky white, beige, lake blue; patterns are: Epiphyllum, flat peach, Xiong Zhu, Yunlong, grid flowers, parquet and so on. 2, the material is light weight, easy to install, waterproof and moisture-proof, anti-borer, and resistant to pollution, good cleaning, sound insulation, good insulation performance, especially in the new process by adding flame retardant material, More secure. 3, PVC gusset material cost is low, so the cost of PVC gusset ceiling is very low, while the installation is also very simple. PVC gusset plate Disadvantages: 1, the general disadvantage of plastic material is the physical performance is not stable enough, so the key problem is that even if the PVC does not encounter water, a long time will be deformed. 2, aging fast, easy to change color, short life, generally 3-5 years looks long for a long time. 3, low environmental protection, waste PVC gusset plate is difficult to deal with, causing pollution to the environment, if with a strong irritating smell of PVC gussets, the body is harmful.

- Q: 2mm thick pvc plastic floor is generally one square meter multiple

- PVC is soft and hard, transparent and opaque, the product is different, the formula is also different, plus plasticizer and filler after the number of no difference, the density is very different, ordinary hard transparent PVC is 1.34 g / cubic Centimeters or so, opaque hard PVC to 1.7 also have, transparent soft PVC minimum to 1.22 or so, opaque do not know. On the fold 1.5g / cubic centimeters = 1500KG / cubic meter. 2mm thick pvc a square meter volume is 0.002 square meters. So 2MM PVC sheet about 3KG weight.

- Q: Can Alcohol Clean Pvc Plate?

- Of course, but to use the high concentration, preferably more than 95%.

Send your message to us

3mm sintra pvc foam board for decoration

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords