3M Packaging Tape - China's Famous Brand Best Quality BOPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

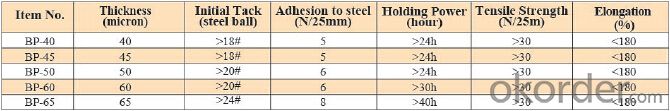

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Does packaging tape come in different thicknesses for added durability?

- Packaging tape indeed comes in various thicknesses to enhance its durability. The thickness of packaging tape is measured in mils, indicating its thickness in thousandths of an inch. Packaging tape typically ranges from 1.6 mils to 3.1 mils in thickness. Opting for thicker tape generally guarantees enhanced durability and the ability to withstand heavy-duty tasks. Thicker tapes are perfect for securing large or heavy packages, as they provide superior strength and resistance against tearing. Conversely, thinner tapes may be more suitable for lighter items or less demanding packaging needs. Consequently, the availability of different thicknesses in packaging tape empowers users to select the most suitable tape that meets their specific durability requirements.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Yes, packaging tape is safe to use on plastic cutting boards. It provides a secure and durable sealing solution that effectively holds the plastic cutting boards together.

- Q: Is packaging tape safe for use on sensitive or confidential documents?

- Using packaging tape on sensitive or confidential documents is not recommended. Packaging tape is meant for sealing boxes and packages, not for ensuring the security or confidentiality of the contents. Its translucent nature makes it easy to remove or tamper with, which compromises the documents' security and confidentiality. Instead, it is advisable to use specialized document security products like tamper-evident envelopes or security labels with tamper-indicating features. These products offer an extra level of protection and guarantee that any unauthorized access or tampering will be noticeable.

- Q: Can packaging tape be used for sealing plastic bags?

- Yes, packaging tape can be used for sealing plastic bags. Packaging tape is designed to have strong adhesive properties that can securely seal items together, including plastic bags. The tape can be applied along the opening or across the entire width of the bag to provide a tight seal and prevent contents from spilling out or being exposed to air and moisture. However, it is important to note that packaging tape may not be as effective as specialized plastic bag sealing methods, such as heat sealing or ziplock closures, which are specifically designed for this purpose.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. It provides a secure and durable seal to keep items inside the basket protected and organized.

- Q: Can packaging tape be used on all types of surfaces?

- Packaging tape can generally be used on a wide range of surfaces, but it is important to consider the specific type of surface and its characteristics. Packaging tape is designed to adhere to various materials such as cardboard, paper, plastic, and even some metals. It is commonly used for sealing boxes and securing packages. However, some surfaces may not be suitable for packaging tape, especially those that are extremely smooth, oily, or coated with a non-stick substance. In such cases, the tape may not adhere properly or may peel off easily. It is always recommended to test the tape on a small, inconspicuous area of the surface before applying it extensively. Additionally, there are different types of packaging tapes available, each with its own specific adhesive properties, so it is important to choose the right tape for the intended surface to ensure proper adhesion and durability.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. Some examples include glossy, matte, clear, colored, patterned, and even customizable options. These variations allow individuals and businesses to choose packaging tape that aligns with their branding or personal preferences.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Indeed, construction materials or tools can be sealed using packaging tape. The primary purpose of packaging tape is to securely seal boxes and packages, which also makes it effective for sealing construction materials or tools. Its strong and durable bond makes it suitable for sealing a wide range of materials, including wood, metal, plastic, or concrete. Nevertheless, it is crucial to take into account the weight and characteristics of the materials being sealed. In instances where heavier or more challenging construction applications are involved, specialized tapes or adhesives specifically intended for construction purposes might be more suitable.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent tearing of packaging tape during application, there are several measures that can be taken: 1. Opt for the appropriate type of packaging tape: It is essential to select a high-quality packaging tape that is specifically designed for heavy-duty applications. Look for tapes that are explicitly labeled as tear-resistant or reinforced. 2. Prepare the surface adequately: Before applying the tape, ensure that the surface is thoroughly cleaned, dried, and devoid of any dust or debris. A dirty or uneven surface can easily cause the tape to tear. 3. Employ the correct technique: When applying the tape, hold the roll at a slight angle in relation to the surface rather than perpendicular. Applying it at an angle will minimize friction between the tape and the surface, thus reducing the likelihood of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, exerting gentle pressure. Avoid pulling or tugging excessively, as it can strain the tape and increase the risk of tearing. 5. Steer clear of extreme temperatures: Extreme temperatures can have an impact on the adhesive properties of the tape, rendering it more susceptible to tearing. If possible, store the tape in a controlled environment and refrain from using it in excessively hot or cold conditions. 6. Consider utilizing a tape dispenser: Employing a tape dispenser can facilitate smoother and more even application of the tape, thereby minimizing the chances of tearing. It also offers improved control and reduces strain on the tape. 7. Cut the tape precisely: When cutting the tape, employ a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make tearing more likely. By adhering to these suggestions, the likelihood of packaging tape tearing during application can be significantly reduced, guaranteeing a secure and dependable seal for your packages.

- Q: What are the different types of packaging tape available?

- There is a wide range of packaging tape options to choose from, each tailor-made for specific purposes and applications. Here are a few commonly used varieties: 1. Transparent packaging tape: This is the most commonly employed type of packaging tape due to its versatility. It is transparent and boasts a strong adhesive bond, making it ideal for sealing boxes and packages. 2. Brown packaging tape: Also referred to as "brown tape" or "packing tape," this tape is typically constructed from brown or tan-colored material and reinforced with fiberglass. It offers exceptional strength and durability for securing heavy or bulky packages. 3. Masking tape: Although not specifically designed for packaging, masking tape can be used for light-duty sealing or labeling needs. It is easily removable and leaves no residue, making it suitable for temporary applications. 4. Duct tape: Renowned for its strength and versatility, duct tape is not primarily intended for packaging purposes but can be utilized in certain situations. It possesses a powerful adhesive bond and is known for its ability to stick to various surfaces, including uneven or rough ones. 5. Filament tape: This tape is fortified with fiberglass filaments, providing incredible strength and resistance. Filament tape is commonly used for bundling or reinforcing heavy or irregularly shaped items. 6. Double-sided tape: Unlike other packaging tapes, double-sided tape has adhesive on both sides and is employed for a variety of applications, such as bonding two surfaces together or mounting objects. 7. Kraft paper tape: Crafted from a renewable resource, kraft paper tape serves as an eco-friendly alternative to plastic tapes. It requires moistening before application as it is water-activated. Kraft paper tape delivers a robust seal and is often utilized for sealing cartons or packages that contain valuable or fragile items. 8. Colored packaging tape: This tape comes in a range of colors and is commonly used for color-coding packages, labeling, or enhancing the aesthetic appeal of packages. These represent just a few of the packaging tape options available in the market. Each type possesses its own distinct characteristics and is suitable for specific packaging requirements. When selecting the appropriate tape, it is crucial to consider factors such as the weight and nature of the package, the environment it will be exposed to, and any specific regulations or requirements that may be applicable.

Send your message to us

3M Packaging Tape - China's Famous Brand Best Quality BOPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords