316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications

Name:Stainless Steel Round Bar

1) Standard:ASTM

2) Material: Stainless steel

3) Grade: 201,202,304,304L,316,316L,321...

4) Shape:round bar

5) Surface: Black, Hairline, Bright, Polished

6) Finish: Cold drawn, Hot rolled

7) Diameter: 4-300mm

8) Length: 1000mm-12000mm

9) Payment terms: T/T 30%payment in advance, 70% T/T before shipment or by L/C

10) Packing: Export sea worthy package

11) Delivery time: Within 30 days after receiving 30%T/T of deposit or L/C

Name | Stainless Steel Round Bar for construction |

Standard | ASTM |

Material | Stainless steel |

Grade | 201,202,304,304L,316,316L,321... |

Surface finish | Black, Hairline, Bright, Polished |

Shape | stainless steel Round bar |

Finish | Cold drawn, Hot rolled |

Diameter | 4-300mm |

Length | 1000mm-12000mm |

Packing | Export sea worthy package |

Delivery | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ | 1MT |

Price terms | FOB, CFR, CIF |

Payment terms | T/T, L/C |

Application | Stainless Steel Round Bar applies to construction,Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistance, electricity industries, etc. |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

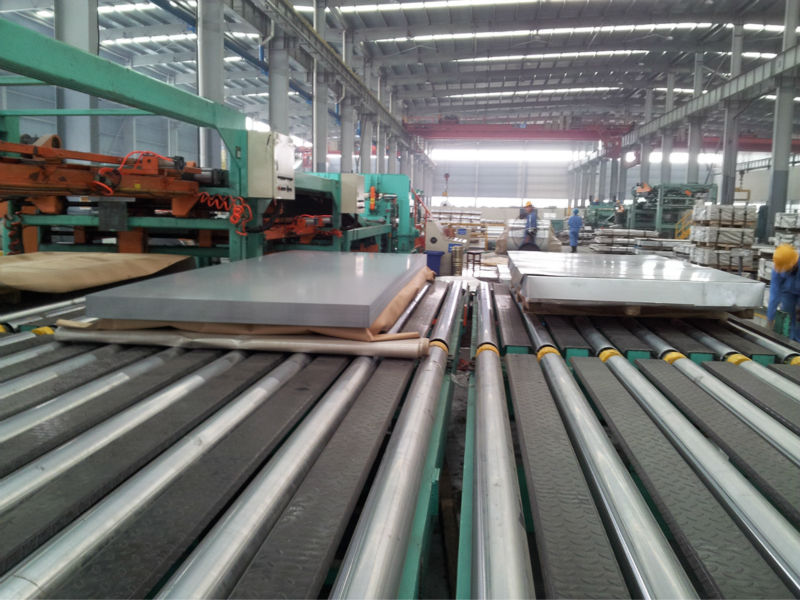

Workshop

Packaging & Shipping

- Q: What is the difference between stainless steel bars and stainless steel hexagons?

- Stainless steel bars and stainless steel hexagons belong to the category of stainless steel products, yet their shape and dimensions distinguish them from one another. Stainless steel bars exhibit a lengthy, solid cylindrical form with a circular cross-section. They come in various sizes and lengths, making them adaptable and extensively utilized in construction, automotive, and industrial sectors. Renowned for their strength, durability, and resistance to corrosion, stainless steel bars serve both structural and decorative purposes. Conversely, stainless steel hexagons, while also composed of stainless steel, possess a hexagonal cross-section. This distinct shape offers additional advantages in specific applications. The six-sided profile of stainless steel hexagons grants superior gripping and torque capabilities, rendering them ideal for fastening components such as bolts, nuts, and screws. The hexagonal shape further ensures stability and prevents rotation, making it well-suited for diverse mechanical and engineering purposes. In essence, the primary distinction between stainless steel bars and stainless steel hexagons lies in their shape and intended applications. Stainless steel bars, being cylindrical, find utility across a broad range of industries, while stainless steel hexagons, with their hexagonal form, are primarily employed for fastening and mechanical applications.

- Q: What are the applications of stainless steel bars in the petrochemical industry?

- Stainless steel bars are widely used in the petrochemical industry for various applications due to their exceptional corrosion resistance, strength, and heat resistance properties. These bars are primarily utilized in the construction of storage tanks, pipelines, and process equipment that handle corrosive fluids and gases. Additionally, stainless steel bars are also employed in the fabrication of heat exchangers, reactors, valves, and fittings, ensuring reliable and long-lasting performance in harsh petrochemical environments.

- Q: What are the different types of stainless steel bars used in chemical reactors?

- There are several types of stainless steel bars commonly used in chemical reactors, including austenitic stainless steel bars (such as 304 and 316 grades), duplex stainless steel bars (such as 2205 grade), and precipitation-hardening stainless steel bars (such as 17-4 PH grade). These different types of stainless steel bars offer varying levels of corrosion resistance, strength, and heat resistance, making them suitable for different chemical processing applications.

- Q: What are the common applications of stainless steel bars?

- Stainless steel bars possess exceptional properties and versatility, enabling them to be widely utilized across various industries. Here are several typical applications of stainless steel bars: 1. Within the construction industry, stainless steel bars are extensively employed for multiple purposes. They serve as reinforcement in concrete structures, including buildings, bridges, and highways. The remarkable strength and corrosion resistance of stainless steel make it an optimal selection for such applications. 2. The manufacturing industry heavily relies on stainless steel bars for fabricating machinery and equipment. These bars are instrumental in producing valves, pumps, shafts, gears, and other components that necessitate high strength and excellent corrosion resistance. 3. The food and beverage industry extensively employs stainless steel bars owing to their hygienic properties. These bars are used in manufacturing food processing equipment like mixers, conveyors, and tanks. Stainless steel bars exhibit corrosion resistance, ease of cleaning, and non-reactivity with food and beverages, rendering them suitable for food processing applications. 4. In the aerospace sector, stainless steel bars are instrumental in manufacturing aircraft parts such as landing gear, engine components, and structural frames. The high strength-to-weight ratio and corrosion resistance of stainless steel position it as an ideal material for these crucial applications. 5. The automotive industry utilizes stainless steel bars in the production of various components, including exhaust systems, chassis, and suspension parts. The exceptional corrosion resistance and durability of stainless steel enable it to withstand harsh environmental conditions and extend the lifespan of automotive components. 6. The medical industry employs stainless steel bars to manufacture surgical instruments, implants, and medical equipment. The biocompatible nature of stainless steel makes it suitable for use within the human body without causing adverse reactions. 7. The energy industry relies on stainless steel bars for manufacturing components utilized in power plants, oil and gas refineries, and renewable energy systems. These bars are employed in constructing pipelines, pressure vessels, and heat exchangers due to their high strength and resistance to corrosion. These examples merely scratch the surface of the common applications of stainless steel bars. The versatility and durability of stainless steel establish it as the preferred choice in various industries where strength, corrosion resistance, and hygiene are vital requirements.

- Q: Can stainless steel bars be used in marine vessel construction?

- Yes, stainless steel bars can be used in marine vessel construction. Stainless steel is highly resistant to corrosion and can withstand the harsh saltwater environment, making it a suitable material for marine applications.

- Q: Are stainless steel bars suitable for oil and gas applications?

- Stainless steel bars prove to be suitable for oil and gas applications, undoubtedly. Owing to its remarkable resistance to corrosion, stainless steel emerges as an ideal choice in environments teeming with oil and gas. The material exhibits exceptional endurance against the harshest conditions and corrosive elements prevalent in these industries, encompassing exposure to chemicals, elevated temperatures, and immense pressure. The strength and durability offered by stainless steel bars further guarantee their long-lasting and dependable performance in oil and gas applications. Moreover, the non-magnetic nature of stainless steel assumes great significance in specific oil and gas processes that mandate the avoidance of magnetic interference. In conclusion, stainless steel bars reign supreme as the preferred material for oil and gas applications due to their corrosion resistance, strength, durability, and non-magnetic properties.

- Q: How are stainless steel bars different from other types of bars?

- Stainless steel bars are different from other types of bars primarily due to their unique composition and characteristics. Firstly, stainless steel bars are made from an alloy of iron and chromium, which provides them with exceptional corrosion resistance. This means that they do not easily rust or corrode when exposed to moisture or harsh environments, making them ideal for a wide range of applications. Furthermore, stainless steel bars possess high strength and durability, making them suitable for heavy-duty applications. Their robustness allows them to withstand significant loads and resist deformation, making them reliable for construction and manufacturing processes. Another distinguishing feature of stainless steel bars is their aesthetic appeal. They have a sleek and lustrous appearance, which adds a touch of elegance to various architectural and decorative designs. This feature makes stainless steel bars a popular choice for interior and exterior applications, including handrails, furniture, and kitchen appliances. Additionally, stainless steel bars offer excellent heat and chemical resistance, making them suitable for applications in extreme temperatures and corrosive environments. They also exhibit good electrical conductivity, making them valuable in electrical and electronic equipment. In summary, stainless steel bars differ from other types of bars due to their exceptional corrosion resistance, high strength, aesthetic appeal, and resistance to heat, chemicals, and electricity. These qualities make stainless steel bars a versatile and reliable choice for a wide range of industries and applications.

- Q: What is the difference between round and square stainless steel bars?

- The main difference between round and square stainless steel bars lies in their shape. Round stainless steel bars have a circular cross-section, while square stainless steel bars have a square cross-section. This shape difference affects their applications and structural properties. Round bars are commonly used in construction, industrial, and manufacturing sectors for applications such as shafts, fasteners, and structural components. Square bars, on the other hand, are often utilized in architectural designs, frames, and braces due to their sharp corners and flat sides that provide enhanced stability and support.

- Q: Are stainless steel bars resistant to scaling?

- Indeed, scaling is resisted by stainless steel bars. Stainless steel, being an alloy comprising chromium, develops a protective layer known as the passive film when it encounters oxygen in the atmosphere. This passive film effectively shields the steel from environmental reactions, scaling, corrosion, and other types of degradation. The remarkable resistance to scaling and other forms of deterioration exhibited by stainless steel bars makes them extensively utilized across diverse industries, including construction, automotive, aerospace, and food processing.

- Q: How do stainless steel bars resist embrittlement?

- Stainless steel bars resist embrittlement due to their unique composition and structure. One of the main factors that contributes to their resistance is the presence of chromium in the steel. Chromium forms a thin, protective oxide layer on the surface of the stainless steel, which acts as a barrier against corrosive substances and prevents the initiation of embrittlement. Additionally, stainless steel bars are alloyed with other elements such as nickel and molybdenum, which further enhance their resistance to embrittlement. Nickel improves the toughness of the steel and reduces the formation of brittle phases, while molybdenum enhances the corrosion resistance and prevents the formation of intergranular corrosion, which can lead to embrittlement. Furthermore, stainless steel bars are often heat treated to optimize their mechanical properties and reduce the susceptibility to embrittlement. Heat treatment processes like annealing or solution annealing help to eliminate internal stresses and improve the grain structure, making the bars more resistant to cracking and embrittlement. In summary, the resistance of stainless steel bars to embrittlement is a result of their composition, protective oxide layer, alloying elements, and heat treatment processes. These factors work together to ensure the bars maintain their mechanical strength and toughness over time, making them ideal for various applications in corrosive environments.

Send your message to us

316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords