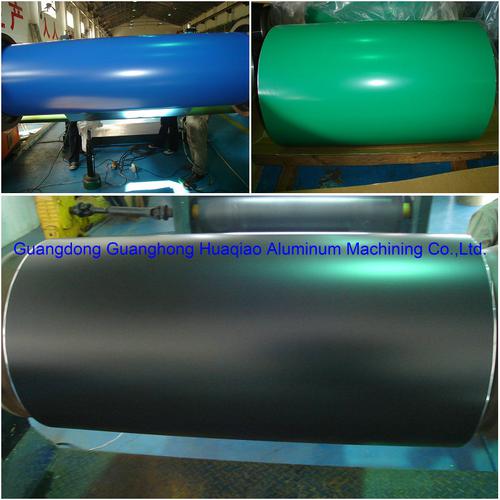

Kynar 3003H16 PE Color Coating Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum magnesium alloy Al-Mn

Second,the Al-Mn-Mg alloys the characteristics of color coated aluminum

Colorcoated aluminum magnesium alloy Al-Mn alloy is used for the 3004 state of theAl-Mn-Mg aluminum alloy substrate, after de-ester, cleaning, passivation layerprocessing, and then painting on this basis, the international most advancedlevel of KANAR500 and HYLAR5000 Series Fluorocarbon (PVDF) resin coating, thecolor coated aluminum manganese alloy known international companies use theU.S. PPG, Sweden and the United States Weishi Bo Beca companies paint company,its products by the natural light exposure, Florida testing, with more than 20years of weathering quality assurance. Color coated aluminum magnesium alloyAl-Mn advantages of raw materials, its products have a high strength, corrosionresistance, high weather resistance and other characteristics, and according totheir own customers were asked to choose a different color palette, you cancolor integration, can co-exist to gorgeous effect.

Third,Al-Mn-Mg alloys the use of color coated aluminum

Ourcompany specializes in aluminum color coated aluminum manganese alloy has beenwidely used in large factories, exhibition halls, stadiums, airports, trainstation roof and ceiling decorative envelope system board. Thickness of thealuminum can choose different color coated aluminum magnesium alloy ofmanganese, by cutting, pressing, punching, bending and other follow-up moldingprocess for large span, the larger the overall roof, wall decorative panelsused in construction; You can also cut into small panels by bending, stampingmold, etc., for indoor decorative roof plate; also with polyurethane foam,bonded aluminum honeycomb composite construction for energy-saving decorativewall plates.

Fourth,the development prospects

As the field of building decoration materials, the continuous improvementrequirements, as poor performance of color coated steel corrosion, rust, yellowrust after a large amount of the deficiency of serious impact on the building'soverall appearance, the urgent need to develop a color plate with bothstrength, but also overcome the shortcomings of color-coated steel, while thereare long-term durability of new materials, building decoration, used inairports, commercial buildings, train stations, subways, hospitals and otherarchitectural decoration. The Al-Mn-color coated aluminum magnesium alloymaterials precisely meet these requirements, with the expanding domesticdemand, strengthen public infrastructure under the principle of color coatedaluminum magnesium alloy of manganese will become an increasingly widespreaduse of aluminum, a good prospect.

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: What’s the loss rate per kg when processing aluminum coil to aluminum sheet?

- Weight=(0.8×1220×2440×2.7)/1000000=6.4kg

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum has a certain level of elasticity and ductility, which allows it to be bent or shaped to a certain extent. However, excessive bending or shaping can lead to cracking, deformation, or even breakage of the aluminum coils. Additionally, the thickness and temper of the aluminum coils can also affect their ability to be bent or shaped. Therefore, it is important to consider these limitations when working with aluminum coils to ensure their structural integrity is maintained.

- Q: What are the potential applications of perforated aluminum coils?

- Perforated aluminum coils have a wide range of potential applications. They can be used in architectural and construction projects for decorative purposes, such as facades, ceilings, and wall cladding. They are also commonly utilized in the automotive industry for grilles and ventilation systems. Additionally, perforated aluminum coils find application in the manufacturing of filters, screens, and acoustic panels due to their ability to efficiently control airflow and sound. The versatility of perforated aluminum coils makes them suitable for various industries, including aerospace, marine, and electronics, where lightweight and corrosion-resistant materials are required.

- Q: Are there any limitations on the bending or forming of aluminum coils?

- The bending or forming of aluminum coils does have limitations. Despite being a relatively malleable metal, aluminum does possess certain constraints in terms of bending or forming. Firstly, one limitation lies in the occurrence of cracks or fractures during the bending process. Unlike other metals, aluminum exhibits lower ductility, making it prone to cracking or breaking under excessive stress or strain. As a result, it is crucial to carefully manage the bending process to prevent over-stressing the aluminum coils and causing damage. Another limitation involves the spring-back effect. When aluminum is bent or formed, it naturally tends to slightly return to its original shape. This poses a challenge in achieving precise and accurate bends or forms, especially with complex shapes or tight tolerances. Moreover, the thickness and grade of the aluminum can impact its bendability. Thicker aluminum coils may necessitate more force or specialized equipment for bending, while different mechanical properties of specific aluminum alloys can influence their formability. To address these limitations, various techniques and tools can be employed. For instance, the use of specialized bending equipment like press brakes or roll forming machines can help control the bending process and minimize the risk of cracking or spring-back. Additionally, preheating the aluminum coils can enhance their ductility, making them more pliable for bending or forming. Considering these limitations and operating within defined parameters is essential for successful bending or forming of aluminum coils. Seeking advice and assistance from experts or manufacturers well-versed in aluminum processing can provide valuable guidance in effectively overcoming these limitations.

- Q: Yep a slogan...the element Aluminum

- Aluminium - Wrap **** in it

- Q: What are the common sizes of aluminum coils used in roofing?

- The common sizes of aluminum coils used in roofing typically range from 24 to 48 inches in width and come in various lengths, ranging from 50 to 100 feet.

- Q: Are aluminum coils resistant to saltwater corrosion?

- Generally, aluminum coils exhibit resistance to corrosion caused by saltwater. Aluminum is widely recognized for its exceptional corrosion resistance, particularly in marine settings where exposure to saltwater is common. The naturally occurring oxide layer on the surface of aluminum acts as a shield, effectively preventing direct contact between the aluminum and the corrosive saltwater. This oxide layer serves as a protective barrier against saltwater corrosion. Moreover, various coating techniques, such as anodizing or painting, can be employed to further enhance the resistance of aluminum coils against saltwater corrosion. Nevertheless, it is worth noting that prolonged or continuous exposure to saltwater can gradually deteriorate the protective oxide layer and potentially result in corrosion, albeit at a slow pace. To prolong the lifespan and optimize the performance of aluminum coils in saltwater environments, regular maintenance and appropriate care are essential.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: Can aluminum coils be used in automotive heat shields?

- Indeed, automotive heat shields can utilize aluminum coils. Thanks to its exceptional resistance to heat and lightweight characteristics, aluminum is extensively employed in heat shield production. By shaping and forming aluminum coils according to the desired design, automotive applications can benefit from straightforward installation and customization. Moreover, the high thermal conductivity of aluminum aids in efficiently dissipating heat, rendering it an optimal option for vehicle heat shields.

Send your message to us

Kynar 3003H16 PE Color Coating Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords