3003 Coated Aluminum Coil for Color Coating Window Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

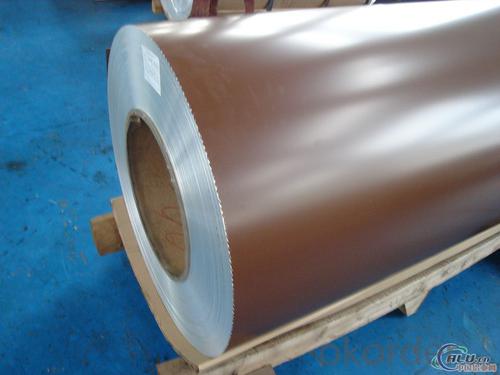

1.Structure of Aluminum Coil for Color Coating Window Panel

Aluminum Coil for Color Coating Window Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminum Coil for Color Coating Window Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminum Coil for Color Coating Window Panel

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA1050 | H18 | 0.2MM-3MM | 1200MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the role of aluminum coils in the construction of sports stadiums?

- Aluminum coils are commonly used in the construction of sports stadiums for their durability, lightweight nature, and excellent thermal conductivity. These coils are typically utilized in the fabrication of roofing systems, façades, and ventilation systems. They provide structural support, weather resistance, and efficient heat transfer, ensuring the longevity and comfort of the stadium. Additionally, aluminum coils offer design flexibility, allowing architects to create visually appealing and modern stadium structures.

- Q: How do aluminum coils contribute to sustainable construction?

- Aluminum coils contribute to sustainable construction through their lightweight nature, recyclability, and energy efficiency. The use of aluminum in construction significantly reduces the weight of structures, leading to less material consumption, lower transportation costs, and reduced energy requirements during construction. Additionally, aluminum is highly recyclable, allowing for the reuse of the material at the end of its life cycle, further reducing waste and environmental impact. Moreover, aluminum coils are known for their excellent thermal conductivity, enabling energy-efficient designs by improving insulation and reducing heating and cooling needs in buildings. Overall, aluminum coils play a crucial role in sustainable construction by promoting resource efficiency, waste reduction, and energy conservation.

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: Can aluminum coils be used in marine environments?

- Yes, aluminum coils can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface when exposed to air, which helps prevent further corrosion. This oxide layer is particularly effective in marine environments where there is exposure to saltwater or high levels of humidity. Additionally, aluminum is lightweight, making it easier to handle and install in marine applications. It is also highly durable and can withstand harsh conditions, including exposure to UV rays and extreme temperatures. Therefore, aluminum coils are commonly used in various marine applications such as boat hulls, shipbuilding, offshore structures, and other marine equipment.

- Q: What is the difference between aluminum coils and aluminum sheets?

- Aluminum coils and aluminum sheets share the same material, aluminum, but they have distinct characteristics. Firstly, their form and shape differ significantly. Aluminum coils are elongated and wound into a coil shape. They find wide application in construction, automotive, and HVAC industries for purposes such as roofing, insulation, and air conditioning systems. In contrast, aluminum sheets are flat and come in various sizes and thicknesses. They are commonly utilized in aerospace, transportation, and packaging industries for aircraft parts, automotive body panels, and food packaging. Additionally, their manufacturing processes are distinct. Aluminum coils are produced using continuous casting, where molten aluminum is poured into a mold and cooled to solidify into a coil. This technique allows for the creation of long, continuous coils. Conversely, aluminum sheets are typically manufactured through a rolling process. The aluminum is passed through a series of rollers that gradually reduce its thickness until the desired sheet thickness is achieved. Consequently, this method enables the production of flat sheets with specific thicknesses. Furthermore, the applications of aluminum coils and sheets also differ. Due to their coil shape, aluminum coils are suitable for applications that require long, continuous lengths like roofing or HVAC systems. On the other hand, the flat shape of aluminum sheets makes them ideal for applications that necessitate a flat surface, such as panel or component manufacturing. To summarize, the main distinctions between aluminum coils and aluminum sheets lie in their form, manufacturing process, and applications. Coils are elongated pieces created through continuous casting, while sheets are flat pieces produced through rolling. The choice between coils and sheets depends on the specific requirements of the application at hand.

- Q: What types of aluminum coils are there that are designed for particular applications?

- <p>Yes, there are various types of aluminum coils designed for specific purposes. For instance, there are coils for construction, which are often used for roofing and siding. Coils for automotive applications are used in manufacturing car parts. Reflective coils are ideal for heat reflection in industries like food processing. Coils for electrical applications are used in transformers and wiring. Each type has specific properties like thickness, strength, and surface finish tailored to meet the requirements of their respective industries.</p>

- Q: Are aluminum coils suitable for electrical insulation applications?

- No, aluminum coils are not suitable for electrical insulation applications. Aluminum is a highly conductive material, meaning it allows the flow of electricity. In electrical applications, insulation is required to prevent the flow of electricity and protect against short circuits or electrical shocks. Therefore, materials with low electrical conductivity, such as plastics, rubber, or fiberglass, are commonly used for electrical insulation purposes.

- Q: What are the potential health hazards associated with the use of aluminum coils?

- <p>There are concerns about the health risks associated with using aluminum coils, particularly in cooking. Aluminum can leach into food when heated, and excessive intake may lead to cognitive impairment and neurological issues. However, the risk is generally considered low with normal usage. It's important to follow proper cooking practices and use utensils that are not reactive with aluminum to minimize exposure. For those with concerns, alternatives like stainless steel or cast iron can be used to reduce potential health risks.</p>

- Q: Can aluminum coils be used in the aerospace industry?

- Yes, aluminum coils can be used in the aerospace industry. Aluminum is widely used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum coils are often used in the manufacturing of various aircraft components such as fuselage panels, wings, and structural frameworks. The coils can be easily formed into different shapes and sizes, providing flexibility in design and reducing the overall weight of the aircraft. Additionally, aluminum coils are compatible with different manufacturing processes like welding, machining, and forming, making them an ideal choice for the aerospace industry.

- Q: Are aluminum coils resistant to oil and grease?

- Yes, aluminum coils are generally resistant to oil and grease.

Send your message to us

3003 Coated Aluminum Coil for Color Coating Window Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords