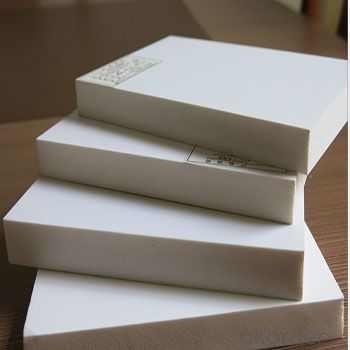

Plastic Sheets - 2024 New Fine White 4x8' 0.5mm Foam Sheet PVC for Factory Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Material Introduction:

PVC is a strong, stiff, low cost plastic material that is easy to fabricate and easy to bond using adhesives or solvents.We know that PVC Sheet and Rod has an exceptional chemical resistance and has high mechanical and tensile strength combined with a high degree of stability which together makes this easily welded product one of the most versatile general purpose plastics available.

2. Material Introduction:

Excellent strength and toughness performance

Flame retarded

Weather resistant,water proof, acid proof, Resistant to chemicals and corrosion., Abrasive-resistant , Excellent UV resistance

Aging-resistant

3. Application:

Construction materials, industrial engineering, semiconductor processing equipment.

Machining: Cutting, sawing, turning, drilling, planing, milling, grinding & screwing.

Forming; Stretch forming, thermoforming, vacuum forming, blow moulding, bending, folding & punching

Welding;Hot-gas, heated-tool & folding.

Eviroment protection,chemical industry,mentallurgy of rare metals, extraction work of rare earth,

Stationery

Package

4. Main Properties of PVC:

1 | Size | 1000x2000mm, 1220x2440mm, 1500x3000mm, etc. |

2 | Thickness | 0.3mm to 60mm |

3 | Width | max 2000mm |

4 | Length | any length |

5 | Density | 1.45g/cm3 |

6 | Material | Polyvinylchloride (100% Virgin PVC Raw Material) |

7 | Type | Rigid PVC Sheet |

8 | Color | Clear, white, black, dark grey, light grey, green, blue, yellow, etc. |

9 | Surface | Smooth ,clean. |

10 | Type | Sheet and Roll are available |

11 | Certification | ISO9001:2000, RoHS |

12 | Packing | Inner packing: Plastic bag; Outer Packing: Carton |

PVC Foam Board Type

pvc celuka foam board, white pvc foam board,black pvc foam board,colored pvc foam board,red pvc foam board,yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.our pvc foam sheet other name is pvc foam board, pvc foam panel, pvc foam plate,rigid pvc foam board,pvc free foam sheet ,pvc plastic foam sheet,pvc forex sheet,pvc crust foam sheet,pvc extruded foam sheet,hard foam pvc sheet,pvc celuka foam sheet,pvc cabinet foam sheet and so on.

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q4: What factors affect the price?

A4: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to

get exact quotation.

- Q: For my Drawing on the Right Side of the Brain course, Betty Edwards includes a view finder containing an overhead projector sheet as one of the materials. I assumed any sheet of plastic (i.e. a plastic sleeve made for a binder) would work, but now I discovered she wants the reader to write on it using a white board marker (and wipe it off afterwards). Any ideas on how I can get a one or two overhead projector sheets, or else, are there any easy alternatives?

- Try an art store. You can often buy individual sheets of various kinds of paper and other materials. The ghetto way would be to scour your home for transparent plastic from product packages and see if any of them work. Lots of things come wrapped in clear plastic, especially electronics. For example, a brand new laptop usually has a clear plastic film over the LCD for protection which would probably be ideal.

- Q: Can plastic sheets be used for mold-making in manufacturing?

- Yes, plastic sheets can be used for mold-making in manufacturing. Plastic sheets are commonly used as mold-making materials due to their ability to be easily shaped, their durability, and their cost-effectiveness. They can be heated and molded into the desired shape, allowing for the creation of complex molds. Additionally, plastic sheets are resistant to many chemicals and can withstand high temperatures, making them suitable for various manufacturing processes.

- Q: Can plastic sheets be used for agricultural purposes?

- Yes, plastic sheets can be used for agricultural purposes. They are commonly used in agriculture for various applications such as greenhouse covers, mulching, and protective covers for crops. Plastic sheets help in regulating temperature, conserving moisture, preventing weed growth, and protecting crops from pests, making them a valuable tool in modern farming practices.

- Q: What are the different types of plastic used in plastic sheets?

- There are several different types of plastic used in plastic sheets, including polyethylene, polypropylene, polyvinyl chloride (PVC), polycarbonate, and acrylic. Each type of plastic has its own unique properties and characteristics, making them suitable for various applications.

- Q: My situation is kind of hard to describe, but I am looking for a company that will sell me some plastic sheets.I have found and asked plenty of companies out there, but none of them seem to carry the type of plastic I need.I am looking for plastic sheets that are from 1mm-3mm thick, and are about as rigid as a Hallmark card.Anyone know where I can get this type of plastic? I don't care about color. Thanks so much.

- Acetate Sheets. ? If they would work you should be able to pick them up at a craft store or even a office store, ie. Staples or Office Max

- Q: Once I went to a workshop, and the moderator used a spray to paste papers in a big plastic sheet. We could remove the papers and paste them again without any problem. Do you know its name and where can I get it? Thank you!

- I've got a can made by 3M. It is called Spray Mount, Artist's Adhesive. I don't know where I bought it years ago, but I shop mostly at Michaels and Hobby Lobby.

- Q: Do plastic sheets have UV protection?

- Yes, plastic sheets can have UV protection. Some plastic sheets are specifically designed and treated with UV inhibitors or filters to block or absorb harmful ultraviolet (UV) radiation. These UV-protected plastic sheets are commonly used in outdoor applications to prevent UV damage, such as yellowing, fading, or degradation caused by prolonged sun exposure.

- Q: Can plastic sheets be used for animal enclosures?

- Yes, plastic sheets can be used for animal enclosures. They are often used as a durable and cost-effective material for constructing enclosures for various animals, such as reptiles, birds, and small mammals. Plastic sheets can provide insulation, easy cleaning, and a clear view for visibility. However, it is important to ensure that the plastic used is safe for the specific animal and appropriate for its needs, taking into consideration factors such as ventilation, durability, and potential hazards.

- Q: Can you use iron on photo transfer sheets (like you use for T shirts) on plastic (like the plastic for phone cases). That's it! Thanks!

- That depends on the melting point of the plastic in question. It would be good to experiment with just one before you make big plans.

- Q: Can plastic sheets be used for outdoor signs?

- Yes, plastic sheets can be used for outdoor signs. They are durable, weather-resistant, and can withstand exposure to sunlight, rain, and other environmental elements. Plastic sheets such as PVC and acrylic are commonly used for outdoor signage due to their versatility and long-lasting properties.

Send your message to us

Plastic Sheets - 2024 New Fine White 4x8' 0.5mm Foam Sheet PVC for Factory Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords