2.0MM Treadmill Diamond Golf Pattern PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2.0MM Treadmill Diamond Golf Pattern PVC Conveyor Belt

1.Product Description:

Our Treadmill conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Easy setting and cleaning, Competitive price and high quality.Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant.

They have different thickness, different patterns, antistatic coating compounds, low noise, long life, high precision, which makes the belts on the treadmill work smoothly and a comfortable running.

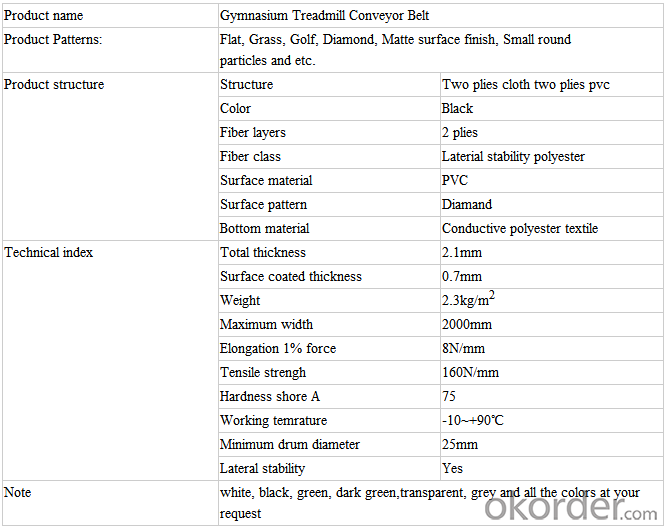

2.Product Specification:

3.Product Advantages:

1).Our treadmill conveyor belts need no lubrication and run quietly and smoothly – without noise or tracking problems.

2).Our treadmill conveyor belts combine low energy sonsuption with durability and an excellent appearance

4.Product Feature:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

5.Product Quality Control

We have very strict quality control system to test all the finished conveyor belts to ensure all the products you receivec are of high quality.

6.Packaging & Shipment

Conveyor belts are packed in rolls and covered by poly woven bags. Also, we can pack it according to your requirments.

7.Product Pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What kind of rubber products are expensive?

- The size and size of rubber products determine the amount of glue used, which is a matter of cost;

- Q: How can I make rubber products brighter?

- The release agent shall have greater tensile strength so that it is not easy to be polished when it is in contact with the molding resin. This is especially true when there are frosted mineral fillers or glass fiber reinforcements in the resins. The release agent shall be chemically resistant so as not to be dissolved in contact with the chemical constituents of different resins (especially styrene and amines). Release agent should also have heat and stress properties, not easy to decompose or wear; release agent should be bonded to the mold, and not transferred to the processed parts, so as not to interfere with painting or other two processing operations.

- Q: Silicone is silicone rubber? Extracted from there?

- Inorganic silica gel is a kind of highly active adsorbent material, which is usually reacted with sodium silicate and sulfuric acid, followed by a series of post treatment processes such as aging and acid foaming.

- Q: Why is natural rubber a strategic material?

- Standard rubber: standard rubber is mainly divided into 5 glue, No. 10 glue and No. 20 glue. Glue No. 5 is the first grade glue. It is the best glue. Its impurity is 0.05%; No. 10 glue is two grade glue, its impurity is 0.10%, 20 glue is three glue, and its impurity is 0.20%. Glue uses different models are not the same: No. 5 commonly used to make rubber tyres; No. 10 and No. 20 rubber glue for making tire.Smoke film: the natural film pressure to the water were smoked after baking film by burning the coconut shell by smoke and heat. The purpose of fumigation is to make the film dry and inject anti oxidation and antiseptic cresol substances. Natural rubber is the primary form of smoke film.Concentrated adhesive: it can be used as bonding material.

- Q: What's rubber skin?

- Rubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: Properties and specific uses of various rubbers

- Natural rubber is mainly derived from the Hevea tree. When the epidermis of this rubber tree is cut open, it will shed milky juice. It is called latex, and the latex will be natural rubber when it is condensed, washed, molded and dried.

- Q: How to solve the exhaust problem in rubber vulcanization process

- Rubber vulcanization process is a process of high temperature, temperature control, temperature will have material evaporation, products not dense gap, excess glue extrusion emissions, sulfide gas release of many factors such as rubber vulcanization requirements must exhaust can produce qualified products.

- Q: How to improve the hardness of rubber?

- 1. selection of high Mooney rubber (high molecular weight);2., increase the dosage of reinforcing agent, or choose the reinforcing agent with high structure and large specific surface area;3. reduce the amount of plasticizer, softener, or use viscosity high plasticizer;4. proper increase of gum content;5., improve the degree of cross-linking (increase the amount of vulcanizing agent, appropriately prolong the curing time, etc.);6., use stiffening resin, high styrene and other hardening agent;7. rubber and plastic combination;8. reduce plasticizing and prevent over refining;

- Q: How can there be a crack in the rubber ring?

- In use, high temperature and exposure to sunlight in the air can cause aging and cracking of NBR

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber material also has excellent heat resistance, cold resistance, corrosion resistance, and little affected by environmental factors, synthetic rubber materials and suitable for 60 to 250 degrees below zero normal use.

Send your message to us

2.0MM Treadmill Diamond Golf Pattern PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords