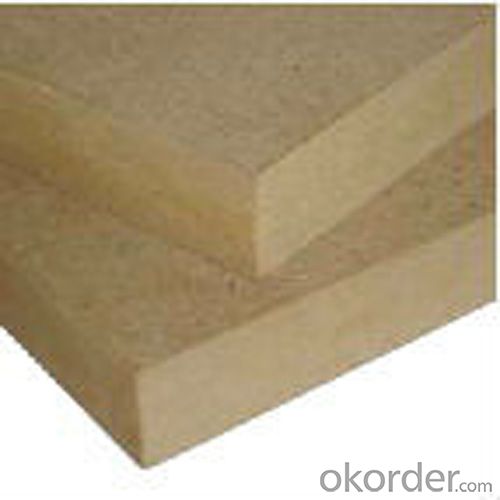

18MM Thickness Plain MDF Board with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Indoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: mdf

· face: plain MDF

· core: poplar

· thickness: 2.3-18mm

· Glue: MR, E2

Packaging & Delivery

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets |

Delivery Detail: | 30days after receiving LC or deposit |

Plain MDF Specification:

1. Special size MDF board as you request

2. Size: 1220x2440mm or as your request

3. Thickness: 2.3mm-18mm

Product Advantage:

1. Customized Groove Type.

2. Good cutting, easy to install, No chipping

3. Famous-brand product, quality assurance

4. Uniform plate density, excellent physics performance; It's close to natural wood but better than natural plank.

5. High strength and good dimensional stability, thickness is2.5mm-30mm,it has been widely used.

6. Good mechanical processing performance, It may use natural wood processing equipment and methods for machining.

7. Flat surface, so It is easy for secondary processing.

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Color steel sandwich panel foam per cubic meter of weight is how much

- 5 cm corrugated sandwich panel double-sided steel plate thickness is 0.3mm foam for 8kg / m3

- Q: Blockboard (sandwich panel) decoration cabinet right?

- Now with the Malacca core blockboard, light and strong, flat without deformation, Malacca this wood is generally used to do musical instruments, you can not be good.

- Q: Suzhou Yanmian sandwich board which is good?

- It is recommended to consider Suzhou Fu new purification equipment Technology Co., Ltd., the company is specialized in the purification equipment R & D and production, purification engineering design, purification engineering construction, purification project maintenance clean room vacuum cleaner, laminar flow hood FFU, clean shed and electrostatic products sales Comprehensive technical services of high-tech enterprises. It can provide professional air purification system engineering design for air electronics, biomedical, hospital operating room, fiber optic cable, food and beverage, precision instrument, semiconductor and new material application, air purification system engineering, air purification system engineering inspection and air Purification system engineering and technical services; according to the customer's actual requirements and the actual needs of the design, manufacture, installation of clean room systems and equipment. So you can consider buying and cooperating.

- Q: I would like to use Caigang sandwich panels to do the indoor ceiling ... how to use what keel .. how the ceiling thank you

- With the color steel sandwich panels do indoor ceiling? Do not understand what is meant, is the indoor do? Color plate ceiling can not use hanging keel, to use 60X60 square tube welding or C steel, and then on the color plate on the top with the tail from the tapping fixed.

- Q: OKorder where to sell rock wool color plate, rock wool sandwich panels and good quality?

- Prices fluctuate at any time

- Q: Sandwich panel wall design please help?

- Is this 127 square? 5.45 and 3.85 are two sides of the width of the original is a large, now divided into two large one small, long is 15 meters, in front of the board height is 3.27 meters. Followed by 2.87 on both sides of the wide plate height is 3.2 meters. So calculated out of 127 square feet

- Q: Sandwich panel prices, and specifications

- Generally 0.4MM-1MM steel clip 50MM foam, rock wool, polyurethane and other things. Prices generally range from 55-180. This depends on the specific circumstances to set, the bubble the cheapest, polyurethane expensive side

- Q: Color steel 50 mm rock wool sandwich board one meter how much the price

- It is not normal to say that there is a flat between 40 and 50

- Q: The main sheet of glass wool cotton sandwich panels

- Glass wool cotton sandwich panel panels made of colored steel plate, stainless steel plate, glass magnesium board three! The price of color steel plate is lower than that of stainless steel plate, so the price of stainless steel glass wool cotton sandwich panel is higher than that of Caigang glass wool cotton sandwich board! Double-sided color steel glass magnesium board as a panel of glass wool cotton sandwich panels need to do hand-made, so the cost of hand-woven glass wool sandwich panels is relatively high!

- Q: Does the country 's steel market have sandwich panels?

- Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Guoqiang steel market with sandwich panels.

Send your message to us

18MM Thickness Plain MDF Board with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords