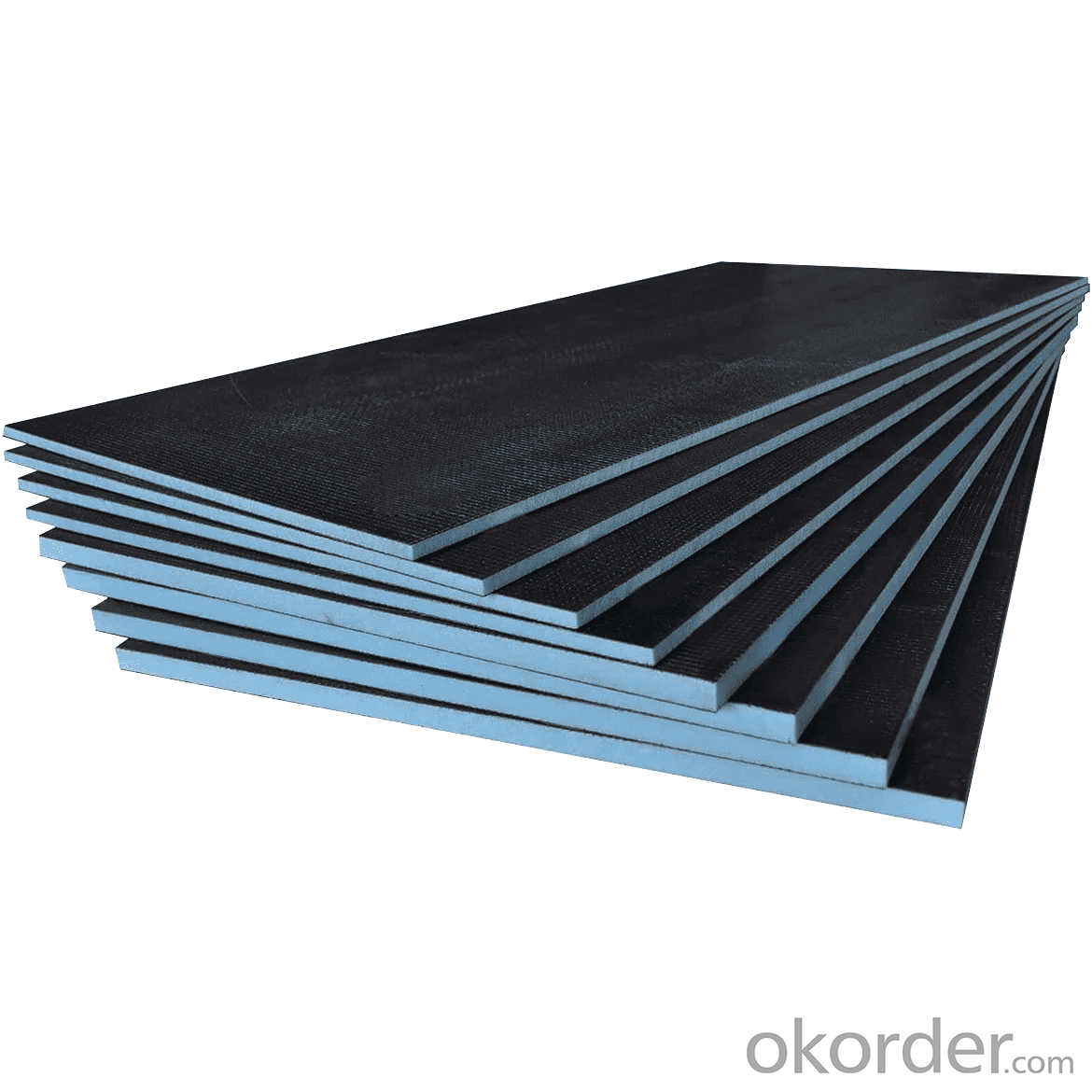

1200x600x12mm waterproof xps tile backer board Building Panel

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wetroom 12mm XPS Tile Backer Board For Walls and Floors 1200mm x 600mm (10 Pack)

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. we offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

we pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

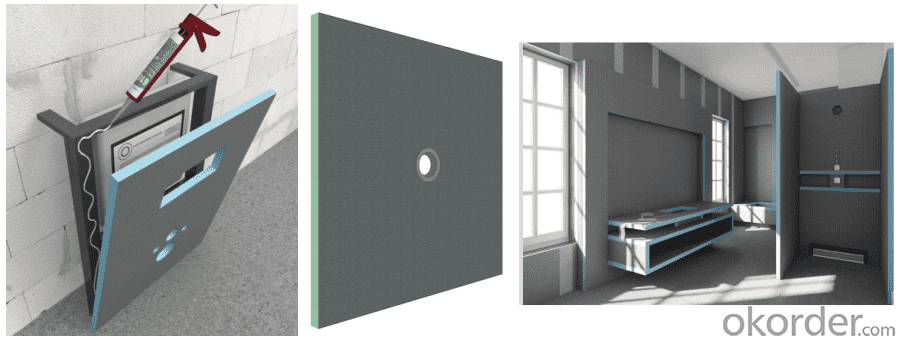

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Oriental rain rain waterproof how to

- 2, Oriental rain rain waterproof coating application If the above content can not accurately explain the East rain rain waterproof paint is good, then continue to look at the East Rainbow waterproof coating since the application of this Examples, I believe that most consumers can not say. Oriental Yuhong waterproof coating with its excellent product performance is applied to the Great Hall of the People, China Millennium Monument, the Three Gorges Hydropower Station, Beijing Metro, Capital Airport, Beijing Wuhuan, Sixth Ring, Beijing-Shanghai high-speed, directly under the central grain depot, China Central Television, National Aquatics Center (Water Cube), National ...

- Q: How does the finished ventilator manufacturer waterproof?

- In the latest country set JJCJ33 clearly stipulates that the structure to be waterproof, refers to the internal ventilation of all nodes and ventilators and roof all the nodes,

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Third, security measures 1, firmly establish the "safety first, prevention first" safety production policy. Before the operation, the site management personnel must be to the operation team to carry out security technology to the end, and actively carry out pre-class security activities, security personnel check, supervise. 2, the roof around the poles outside the scaffolding (protective railings), roof construction is strictly prohibited removal. 3, roof construction, debris and other materials is strictly prohibited from the roof directly down throwing. 4, storage of coils and adhesives warehouse or site to prohibit the fireworks, for the use of fire, there must be fire prevention measures, and should set a certain number of fire extinguishers and sand bags. 5, oil drums should be flat, not two carrying, in the transport process, pay attention to balance, the spirit to focus, to prevent accidental fall caused harm. 6, transported to the roof of the material, should be scattered on average, with the use of transport, not concentrated stacking. 7, the use of torch, you should clear the surrounding flammable items, must be away from the base of oil, is strictly prohibited in the brush base oil area using the torch. Torch petrol should not be over full, cheer should not be too much, in the fire site must be equipped with fire equipment.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 5, plastic runway laying completed, maintenance and maintenance 7 to 10 days before they can be used normally.

- Q: What are the key points and contents of the quality control of waterproof material?

- 3, infiltration of crystalline cement-based waterproof coating: on-site fraud is to use ordinary cement mixed with seafood powder (or 801 glue) so that the cement after the solidification of the color, it will not crack. Genuine infiltration of crystalline cement-based waterproof coating will have a hydrophobic effect that is the effect of lotus leaf water droplets (of course, this hydrophobic effect can not be too much, otherwise it will affect the next process of bonding).

- Q: Why should the use of high pressure perfusion waterproof plugging method

- Due to uneven settlement of buildings and other factors, resulting in deformation of the building structure cracking, leakage phenomenon, for the repair of this situation, you can use a new foreign plugging construction technology - high pressure grouting waterproof repair technology.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 3: waterproof gypsum board ????Waterproof gypsum board is in the gypsum core by adding a certain amount of waterproof plastic made of products, so waterproof gypsum board has a certain waterproof function, while gypsum board paper is also a waterproof measures, is a more widely used materials. Waterproof gypsum board with the effect of thermal insulation, but also has the advantages of fire, noise, but also an easy decoration materials. There is also a feature of the characteristics of environmental protection, due to the use of natural gypsum as a raw material, in the home environmental protection is guaranteed.

- Q: Waterproof material water leakage construction should pay attention to what

- 2, wall treatment · Wall treatment to do about 300mm high waterproof coating, to prevent water infiltration wall back tide. · Bathroom between the wall and the ground (plane and elevation) brushing height should be greater than 100mm. · The height of the shower room in the bathroom is not less than 1800mm. · If there is a bathtub, the height of the wall adjacent to the bathtub should be 300mm higher than that of the bathtub. · Waterproof height of tub is not less than 800mm. · The height of the squat should be more than 900mm. For the transformation of the toilet wall and self-built light wall, the proposed height of the waterproof to do the top.

Send your message to us

1200x600x12mm waterproof xps tile backer board Building Panel

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products