1 4 Brushed Aluminum Sheets - High Quality Decoration and Roofing Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Decoration and Roofing Aluminum Coil Description:

Mill Finish Plain Aluminum are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Decoration and Roofing Aluminum Coil:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

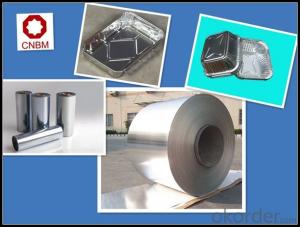

3. Decoration and Roofing Aluminum Coil Images:

4. Decoration and Roofing Aluminum Coil Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets fire-resistant?

- Yes, aluminum sheets are fire-resistant.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: What are aluminum sheets made of?

- Pure aluminum or aluminum alloy is typically used to make aluminum sheets. Aluminum alloy is a mixture of aluminum and other elements like copper, magnesium, or zinc. The composition of the alloy varies depending on the intended use and desired properties of the sheet. Pure aluminum sheets are softer and easier to shape, while alloyed aluminum sheets provide greater strength, durability, and resistance to corrosion. To produce the sheets, a rolling process is employed, where a large block or ingot of aluminum is passed through rollers to decrease its thickness and form the desired size of the sheet.

- Q: Are aluminum sheets suitable for electrical applications?

- Yes, aluminum sheets are suitable for electrical applications. Aluminum is a highly conductive metal, and its use in electrical applications has become increasingly popular due to its numerous advantages. Firstly, aluminum is lightweight and offers excellent heat dissipation properties, making it an ideal choice for applications that require efficient thermal management. This is particularly important in electrical systems where heat can be generated, such as power transmission lines, electrical panels, and heat sinks. Secondly, aluminum sheets are highly corrosion-resistant. Unlike some other metals, aluminum forms a protective oxide layer on its surface, preventing further oxidation and corrosion. This makes it a reliable choice for electrical applications that are exposed to harsh environments or moisture. Additionally, aluminum is a cost-effective option compared to other metals commonly used in electrical applications, such as copper. It is readily available and has a lower price point, making it an attractive choice for manufacturers and consumers alike. However, it is important to note that aluminum has a lower electrical conductivity compared to copper. This means that for certain applications where high conductivity is crucial, such as in power transmission lines, copper may still be preferred. Nevertheless, advancements in technology and design have allowed aluminum to be used effectively in a wide range of electrical applications, from wiring and connectors to bus bars and transformers. In conclusion, aluminum sheets are indeed suitable for electrical applications, offering benefits such as lightweight construction, excellent thermal management, corrosion resistance, and cost-effectiveness. The final decision on whether to use aluminum or another material ultimately depends on the specific requirements and constraints of the electrical application in question.

- Q: Can aluminum sheet be used for decorative purposes?

- Indeed, aluminum sheet serves as a suitable option for decorative uses. With its adaptability, aluminum can be effortlessly molded, trimmed, and fashioned into an assortment of patterns, rendering it an excellent choice for embellishing ventures. Whether utilized to fashion decorative paneling, sculptures, signage, furnishings, or numerous other ornamental components, aluminum proves itself indispensable. Furthermore, aluminum can be anodized or painted in an extensive array of hues, enabling additional personalization and accentuating its visual allure. Additionally, its lightweight composition and corrosion resistance render it a pragmatic selection for both indoor and outdoor decorative endeavors.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Are aluminum sheets suitable for outdoor signage?

- Yes, aluminum sheets are highly suitable for outdoor signage. Aluminum is a durable and weather-resistant material that can withstand the harsh outdoor elements, including rain, wind, and sunlight. It is corrosion-resistant, which makes it ideal for long-term outdoor use. Additionally, aluminum sheets are lightweight, making them easy to handle and install. They can be easily cut, bent, or shaped to create various signage designs. Aluminum also offers a sleek and professional appearance, making it a popular choice for outdoor signage in commercial and industrial settings.

- Q: Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q: What is the typical thermal conductivity of aluminum sheets?

- The typical thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin (W/mK). This high thermal conductivity makes aluminum an excellent heat conductor, which is why it is commonly used in applications where heat transfer is important, such as in heat sinks, power transmission lines, and cooking utensils.

- Q: Hi,I need some interesting facts about AluminiumLike who found/discovered it, and how, or/and history of it. Recycling it, or does it have effects on the environment,Thanks if you can help,Thank you thank you thank you!Xx

- Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. all the ifo u need isat the link below

Send your message to us

1 4 Brushed Aluminum Sheets - High Quality Decoration and Roofing Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords