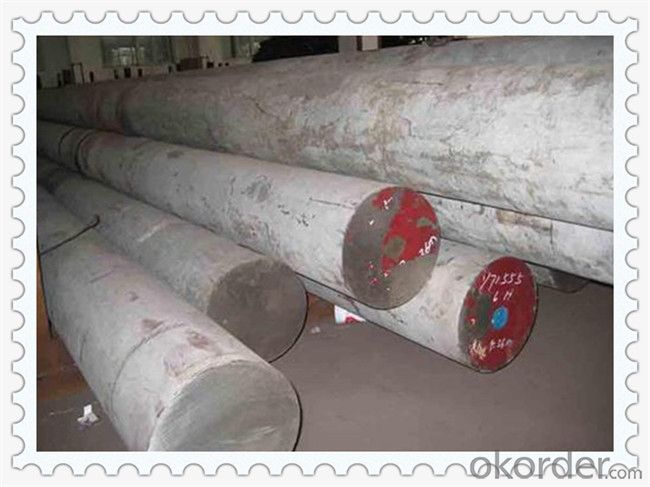

1.2311 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2311 Steel Round Bar

Grade: 3Cr2Mo/P20/1.2311/Bp20

Characteristic

1, Good hardenability.

2, Polished good performance

3, Good mechanical properties.

4, Section's hardness is uniform.

Chemical composition of 3Cr2Mo

| C | Si | Mn | Cr | Mo | P | S |

| 0.28~0.40 | 0.20~0.80 | 0.60~1.00 | 1.40~2.00 | 0.30~0.55 | ≤0.030 | ≤0.030 |

Specification

Round bar | Diameter (mm) | Length (mm) | |

50~500 | 2000~5800 | ||

plate/sheet | Thickness (mm) | Width (mm) | Length (mm) |

20~400 | 80~1000 | 2000~5800 |

Steel Surface

Steel Sharp | Surface treatment |

Round bar | Black /Grinding / Polished / Peeled / Turned |

steel plate | Black / Milling / Machined |

Application

1. 3Cr2Mo is suitable for making medium and large,sophishticated long-life plastic mold steel.

2. 3Cr2Mo is suitable for manufacturing low melting point alloy die casting and heavy mold main components.

Physical properties

Thermal conductivity

| Temperature/°c | 20 | 100 | 200 | 300 | 400 |

| Thermal conductivityλ/W•(m•K)¯¹ | 36.0 | 33.4 | 31.4 | 30.1 | 29.3 |

Coefficient of expansion

| Temperature/°C | 18~100 | 18~200 | 18~300 | 18~400 | 18~500 | 18~600 | 18~700 |

| Coefficient of expansion/°C-1 | 11.9*10-6 | 12.20*10-6 | 12.5*10-6 | 12.81*10-6 | 13.11*10-6 | 13.41*10-6 | 13.71*10-6 |

Company equipment

smelting equipment : 3 and 4 tons induction furnaces;electric slag furnaces of 0.5t,1t,3t,5t,especially 3 and 5 tons electric slag

furnaces which feature both unipolar and bipolarity series functions.etc.

Processing equipments : electric hydraulic hammer; supporting equipments, gas producer, reheating furnace, gas annealing

furnace, electric annealing saw, etc.

Detective equipments : functions of chemical annalysis, physics property and mechnical property, etc.

- Q: What are the advantages of using cobalt-alloy steel round bars?

- Using cobalt-alloy steel round bars in various industries and applications offers several advantages. Firstly, this type of steel is exceptionally strong and hard, providing resistance against wear, corrosion, and high temperatures. This makes it suitable for demanding environments where other materials would quickly degrade. Secondly, cobalt-alloy steel maintains its shape and size even under extreme conditions, demonstrating excellent dimensional stability. This makes it ideal for applications that require precise tolerances and minimal deformation, such as in the aerospace and automotive industries. Moreover, cobalt-alloy steel retains its mechanical properties at elevated temperatures, showcasing excellent heat resistance. This makes it valuable in applications involving high-speed machining, cutting tools, and turbine components. Additionally, cobalt-alloy steel round bars are easily machined and fabricated, offering versatility and customization in various applications. Their high machinability and weldability make them suitable for use in manufacturing processes like forging, casting, and machining. Furthermore, cobalt-alloy steel round bars exhibit excellent fatigue resistance, ensuring long-lasting performance and durability. This makes them suitable for applications involving repetitive stress or cyclic loading, such as shafts, springs, and fasteners. Lastly, cobalt-alloy steel is biocompatible, making it suitable for medical and dental applications. Its corrosion resistance and biocompatibility properties make it commonly used in orthopedic implants, surgical tools, and dental instruments. In conclusion, the advantages of using cobalt-alloy steel round bars include exceptional strength, hardness, and dimensional stability, as well as heat resistance, machinability, fatigue resistance, and biocompatibility. These qualities make them valuable across a wide range of industries and applications, offering reliability, durability, and performance.

- Q: What are the different types of defects that can occur in steel round bars?

- There are several types of defects that can occur in steel round bars. These defects can vary in their severity and impact on the overall quality and performance of the bars. Some of the common types of defects found in steel round bars include: 1. Surface defects: These defects are visible on the external surface of the bar and can include scratches, pits, and scaling. While surface defects may not affect the structural integrity of the bar, they can impact its aesthetic appeal and can potentially lead to corrosion if not properly addressed. 2. Internal defects: Internal defects are imperfections that occur within the body of the steel round bar. These defects can include voids, inclusions, and segregation. Internal defects can weaken the bar's mechanical properties and compromise its structural integrity. They can also lead to cracking or failure under stress. 3. Dimensional defects: Dimensional defects refer to variations in the size or shape of the steel round bar. These defects can occur during the manufacturing process and can include variations in diameter, length, or straightness. Dimensional defects can affect the bar's functionality and compatibility with other components in a structure or machinery. 4. Decarburization: Decarburization is a defect that occurs when the surface layer of the steel round bar loses carbon due to exposure to high temperatures during manufacturing or heat treatment processes. This defect can weaken the bar's hardness and strength, making it more susceptible to wear, fatigue, or failure. 5. Lamination: Lamination defects occur when there are layers or separations within the steel round bar. These defects can result from improper rolling or processing techniques. Lamination defects can reduce the bar's strength and ductility, making it prone to fracture or failure. 6. Incomplete heat treatment: Heat treatment is often used to enhance the mechanical properties of steel round bars. However, if the heat treatment process is not performed correctly or if there are inconsistencies in the cooling or reheating process, the bar may have incomplete or uneven heat treatment. This can result in variations in hardness, strength, or toughness along the length of the bar. It is important to note that the severity and impact of these defects can vary depending on the specific application and requirements of the steel round bar. Manufacturers and quality control teams employ various testing and inspection methods to detect and mitigate these defects, ensuring that the bars meet the necessary standards and specifications.

- Q: What is the difference between a rough turned and a precision ground steel round bar?

- A rough turned steel round bar refers to a steel bar that has undergone a rough machining process to remove excess material and bring the bar to a closer approximation of its final dimensions. This process typically involves removing the outer layer of the bar through turning or other machining methods. However, the bar is not yet finished to precise tolerances and may still have slight variations in diameter or surface roughness. On the other hand, a precision ground steel round bar has undergone a secondary machining process known as grinding. Grinding is a more precise and controlled method of removing material from the surface of the bar. It involves using a grinding wheel or abrasive tool to carefully remove small amounts of material, resulting in a bar with highly precise dimensions and a smoother surface finish. Precision ground bars are typically made to meet specific tolerances and have a more consistent diameter, surface finish, and straightness compared to rough turned bars. The main difference between a rough turned and a precision ground steel round bar is the level of precision and surface finish achieved. Rough turned bars are suitable for applications where tight tolerances and surface finish are not critical, such as in certain structural or machinery components. Precision ground bars, on the other hand, are preferred when precise dimensions, tight tolerances, and a smooth surface finish are required, such as in precision machining applications or where the bar will be used as a shaft or component in critical machinery or equipment.

- Q: 12mm Round steel, the material is Q235, the maximum weight can bear?

- The cross sectional area of 12mm steel is 3.14*36=113.04 mm, the maximum can bear much weight: 113.04*235=26564.40 cattle, is about 26.56440 kn.

- Q: How do you measure the diameter tolerance of a steel round bar?

- To determine the diameter tolerance of a steel round bar, one can adhere to the following procedure: 1. Acquire a caliper or micrometer, which are commonly employed tools for accurately gauging object diameters. 2. Set up the measuring tool appropriately: Adjust the jaws of the caliper to the suitable size range or ensure correct zeroing of the micrometer. 3. Situate the round bar: Place the steel round bar on a stable and flat surface, taking care to prevent any rolling or movement. 4. Perform the measurement: Utilize the measuring tool to record the diameter of the round bar. For precise outcomes, ensure that the tool is perpendicular to the bar and exert gentle pressure to obtain an accurate reading. 5. Repeat the measurement: To ensure accuracy, take multiple measurements at various points along the length of the round bar. This will account for any variations or deviations in the bar's diameter. 6. Calculate the average diameter: Sum up all the measurements and divide by the number of measurements taken. This will yield the average diameter of the round bar. 7. Compare with the tolerance range: Refer to the provided specifications or standards for the steel round bar to ascertain the allowable tolerance range. This range will indicate the acceptable variation in diameter for the bar. 8. Analyze the findings: Compare the average diameter derived from the measurements with the specified tolerance range. If the average diameter falls within the tolerance range, the round bar complies with the required specifications. However, if it deviates beyond the range, further inspection or adjustment may be necessary to meet the required tolerance. By adhering to these steps, one can effectively gauge the diameter tolerance of a steel round bar and ensure its conformity to the necessary specifications for the intended application.

- Q: Are steel round bars suitable for outdoor sculptures?

- Indeed, outdoor sculptures can be made with steel round bars. Steel, being a resilient and robust substance, can endure severe weather conditions, including rain, snow, and extreme temperatures. It possesses resistance against corrosion, making it an ideal option for outdoor applications. The malleability of steel round bars allows for effortless shaping and welding, enabling the creation of intricate and elaborate sculptures. Furthermore, steel can be coated with diverse finishes, such as powder coating or paint, to provide additional protection against the elements and enhance its aesthetic appeal. In summary, steel round bars offer the requisite strength, durability, and adaptability necessary for outdoor sculptures.

- Q: What are the advantages of using spring steel round bars?

- There are several advantages of using spring steel round bars: 1. High strength: Spring steel round bars are known for their exceptional strength. They are designed to withstand high levels of stress and strain, making them ideal for applications that require strong and durable materials. 2. Flexibility: Spring steel round bars have excellent flexibility, allowing them to be easily shaped, bent, or formed without losing their strength. This flexibility makes them suitable for various manufacturing processes and applications. 3. Superior elasticity: Spring steel round bars possess excellent elasticity, enabling them to return to their original shape after being subjected to deformation or stress. This elasticity is crucial in applications where materials need to absorb shocks or vibrations. 4. Resistance to fatigue: Spring steel round bars are highly resistant to fatigue and can withstand repeated cycles of loading and unloading without losing their mechanical properties. This resistance to fatigue ensures their reliability and longevity, making them suitable for demanding applications. 5. Excellent toughness: Spring steel round bars exhibit exceptional toughness, which means they can withstand sudden impact or heavy loads without breaking or fracturing. This characteristic makes them suitable for applications that require materials to withstand harsh environments or heavy-duty operations. 6. Corrosion resistance: Many spring steel round bars are made from corrosion-resistant alloys, providing protection against rust and other forms of corrosion. This corrosion resistance makes them suitable for applications where exposure to moisture or corrosive substances is expected. 7. Cost-effective: Spring steel round bars offer a cost-effective solution compared to other types of steel or materials. Their durability and longevity reduce the need for frequent replacements, ultimately saving costs in the long run. In summary, the advantages of using spring steel round bars include high strength, flexibility, superior elasticity, resistance to fatigue, excellent toughness, corrosion resistance, and cost-effectiveness. These properties make them a preferred choice in various industries, including automotive, construction, manufacturing, and aerospace.

- Q: What are the different types of steel round bars used in the automotive aftermarket?

- There are several different types of steel round bars commonly used in the automotive aftermarket. These include: 1. Carbon Steel Round Bars: Carbon steel is a commonly used material in the automotive industry due to its high strength and durability. It is often used in applications that require heavy-duty performance, such as suspension components, drive shafts, and steering linkages. 2. Alloy Steel Round Bars: Alloy steel is a type of steel that has been alloyed with other elements to enhance its mechanical properties. It is commonly used in the automotive aftermarket for applications that require high strength, such as crankshafts, camshafts, and axles. 3. Stainless Steel Round Bars: Stainless steel is known for its corrosion resistance and aesthetic appeal. It is often used in automotive aftermarket applications that require resistance to harsh environments, such as exhaust systems, trim components, and decorative elements. 4. Tool Steel Round Bars: Tool steel is a type of high-carbon steel that is specifically designed for tooling and machining applications. It is commonly used in the automotive aftermarket for manufacturing specialized tools, dies, and molds. 5. Bearing Steel Round Bars: Bearing steel is a type of high-carbon steel that is specifically designed for bearing applications. It is commonly used in the automotive aftermarket for manufacturing bearings and other rotating components. These are just a few examples of the different types of steel round bars used in the automotive aftermarket. The specific type of steel chosen for a particular application will depend on factors such as the required strength, durability, and corrosion resistance.

- Q: What are the different types of steel round bar finishes?

- There are several different types of steel round bar finishes, including hot rolled, cold drawn, turned and polished, and ground and polished.

- Q: How are steel round bars used in the construction of transmission towers?

- Steel round bars are commonly used in the construction of transmission towers due to their strength, durability, and ease of fabrication. These bars are typically made from high-strength carbon steel and are available in various diameters to suit different structural requirements. In the construction of transmission towers, steel round bars are primarily used as the main structural elements. They form the vertical and diagonal members that provide strength and stability to the tower. The bars are typically connected together using various methods like welding or bolted connections to form the lattice structure of the tower. The round shape of the bars allows for uniform distribution of forces, making them ideal for withstanding the loads and stresses that transmission towers experience. These loads include the weight of the tower itself, the electrical conductors, and environmental factors like wind, ice, and seismic forces. Additionally, steel round bars offer excellent corrosion resistance, which is crucial for transmission towers that are often exposed to harsh weather conditions. This resistance helps to prolong the lifespan of the tower and ensures the safety and reliability of the transmission lines. Furthermore, steel round bars can be easily fabricated and customized according to the specific design requirements of the transmission tower. They can be cut, bent, and shaped into the desired dimensions, allowing for flexibility in tower design and construction. Overall, steel round bars play a vital role in the construction of transmission towers by providing strength, durability, and resistance to corrosion. Their versatility and ability to withstand various loads make them an essential component in ensuring the safe and reliable transmission of electricity.

Send your message to us

1.2311 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords