040 Aluminum Coils - Decorative Coated Aluminum Coil 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Decorative Coated Aluminum Coil 3003 H14

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

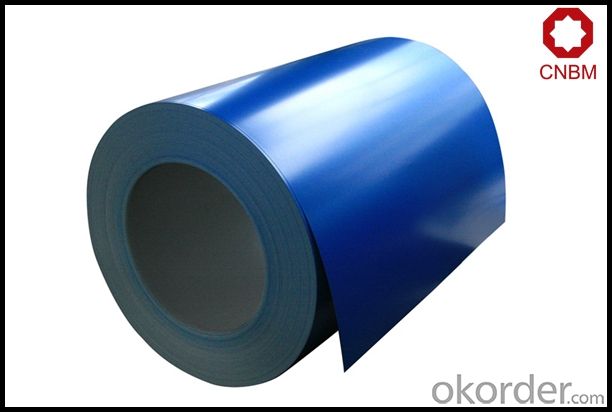

13) Surface: Bright

14)Origin: China

2. Application of Decorative Coated Aluminum Coil 3003 H14

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Decorative Coated Aluminum Coil 3003 H14

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

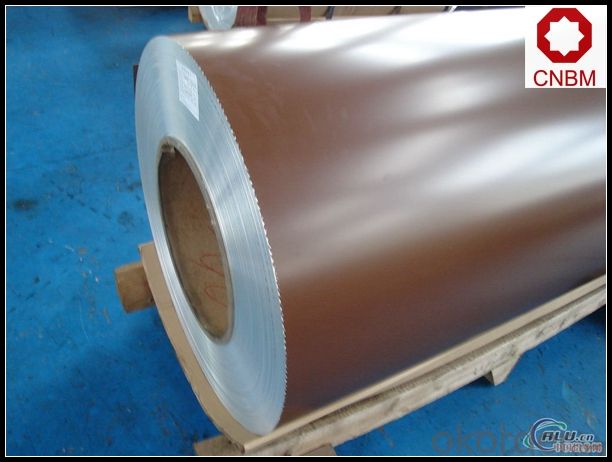

5. Image of Decorative Coated Aluminum Coil 3003 H14

6. Package and shipping of Decorative Coated Aluminum Coil 3003 H14

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils affected by magnetic fields?

- No, aluminum coils are not affected by magnetic fields as aluminum is not a magnetic material.

- Q: I am sanding tool marks out of aluminum rims and plan on polishing them. Any help to make sanding them easier would be welcome.

- Sanding aluminum is hard work . you need to start out with a 800 grit to get the tool marks out. Then to polish, you need to strip all of the paint (if any ) off. I recommend using a 1000 grit wet sand paper in a single direction, back and forth, not circles. I also recommend using Mothers aluminum mag wheel polish (works on any polishable metal) at the same time. again it is hard work, lots of elbow grease! But it does pay off as it looks better than chrome, I also dont reccomend using power tools as you might end up taking to much off of a surface causing a wavy apperance, after a 1000 grit you could go up to 1200 grit for a mirror finish!

- Q: i need ONE advantage of each, and a final reason why aluminium is used?

- Copper and Aluminum are both great conductors of electricity. Aluminum is actually more dangerous than copper, as it expands/contracts a lot more with heat, and is a primary cause of house fires. Copper's advantage is that it is more reliable, it doesn't corrode as easily, and does not expand/contract much with application of heat. I believe that aluminum has an edge as a conductor, though, and is less expensive to manufacture.

- Q: Can you create a tank, AFV, IFV etc. from aluminium or is this just a stupid idea that would kill everyone inside?

- Most military vehicles these days are made out of a super high grade strength linoleum. That way, if they're ever needed to be lifted out by a helicopter or some other flying vehicle, they're light enough. And it also is easier to repair damage and clean off blood stains as compared to other types of metal.

- Q: How are aluminum coils used in the production of air ducts?

- Due to its unique properties and benefits, aluminum coils find extensive use in the manufacturing of air ducts. Firstly, aluminum's lightweight nature makes it convenient to handle and install during the duct manufacturing process, thereby reducing the overall weight of the air duct system and facilitating easier transportation and installation. Secondly, aluminum coils possess high resistance to corrosion, which is particularly crucial for air ducts that are constantly exposed to moisture and various environmental factors. This resistance ensures that the air ducts maintain their structural integrity and longevity, reducing the need for frequent maintenance and replacement, thereby minimizing costs. Furthermore, aluminum coils exhibit excellent thermal conductivity, enabling air ducts to efficiently transfer air at the desired temperature. This promotes enhanced energy efficiency and reduced energy consumption. The even distribution of temperature throughout the air ducts also contributes to maintaining a comfortable indoor environment and reducing the workload on HVAC systems. Additionally, the malleability of aluminum coils allows them to be easily shaped and customized to fit specific requirements. This flexibility in design facilitates better utilization of available space and seamless integration into different building structures. Lastly, aluminum is a sustainable material that can be recycled multiple times without losing its properties. This makes it an environmentally friendly choice for air duct production, reducing the environmental impact associated with manufacturing processes. In summary, aluminum coils are essential in the production of air ducts due to their lightweight, corrosion-resistant, thermally conductive, customizable, and sustainable characteristics. These properties contribute to the efficient functioning of HVAC systems, energy savings, and environmental sustainability in the construction industry.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks.

- Q: Can aluminum coils be painted or coated with other materials?

- Yes, aluminum coils can be painted or coated with other materials. This process is commonly done to enhance the appearance, protect against corrosion, or improve thermal insulation properties of the coils.

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, making them convenient to handle and position during installation. Additionally, they can be easily cut and shaped to fit the desired space, making the installation process relatively straightforward for experienced professionals or DIY enthusiasts.

- Q: What are the various applications and purposes of aluminum coil in different industries?

- <p>Aluminum coil is widely used in numerous applications due to its lightweight, corrosion resistance, and high strength. It is commonly used in construction for roofing and siding, in the automotive industry for body panels and heat exchangers, and in the packaging industry for food and beverage cans. Aluminum coil is also utilized in electrical applications such as transformers and wiring, and in the manufacturing of everyday items like foil and cookware. Its versatility makes it a popular material in various industries.</p>

- Q: This question asks for the current market price of aluminum coils.

- <p>The price of aluminum coils can vary significantly based on factors such as grade, thickness, width, and market conditions. As of my last update, prices fluctuate daily due to global supply and demand, economic indicators, and geopolitical events. For the most accurate and up-to-date pricing, it's best to consult with metal suppliers or check commodity exchanges like the London Metal Exchange (LME). Prices are typically quoted in dollars per metric ton and can range from a few thousand to several thousand dollars depending on the aforementioned factors.</p>

Send your message to us

040 Aluminum Coils - Decorative Coated Aluminum Coil 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords