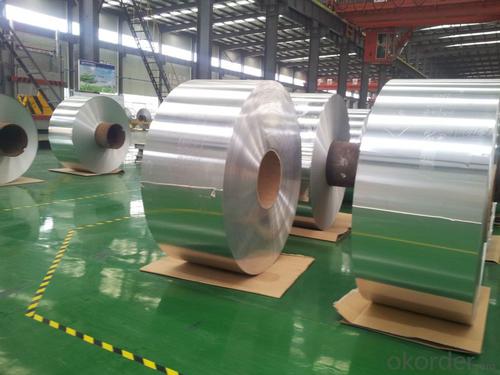

026 Aluminum Coil - 6083 T5 Aluminum Alloy Plate/Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 90000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

low price with high quality

free sample

efficiently and professionally delivery

good service

aluminum coil 1050 1060 1070 1100 1235 | | |||

Alloy | Thickness(mm) | Width(mm) | Temper | DC or CC |

0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

ID | 505mm,75mm,150mm etc. | |||

Packing | eye to wall | | ||

eye to sky | | |||

Application | Mainly in printing(PS plate base), Aluminum-plastic composite panel base, construction, decoration, capacitor, cover material, deep drawing products, refrigeration, air conditioner, automobile etc. | |||

6000 series aluminium alloy plate, generally called Al-Mg-Si alloy, the magnesium and silicon are used as main alloy element. Feature: most the advantages of 4000 series & 5000 series alloy, good corrosion resistant performance, well welding property, good oxidability, easy to spray-finishing,well oxidation coloring, good machinability, middle strength, often used used after heat treatments.

- Q: Is it possible to use aluminum coils as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used to make jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and art pieces. It's easy to work with, allowing for intricate designs and shapes. However, it's important to note that aluminum is not as valuable or as resistant to tarnishing as precious metals like gold or silver, so it may not be suitable for high-end or long-lasting jewelry pieces.</p>

- Q: Is there any way aluminum can affect you if its absorbed into your body either by digestion, through an open cut, or even through breathing it in?Most likely inhaling it would surely affect you, but what about the other two?

- Aluminium can accumulate in the brain possibly causing alzheimers. If you inhaled it it would poison you and damage your lungs, if you got it in your body it would damage your skin, possibly cause an infection and the cut might not heal. Aluminium is a solid so how could you accidently get it in your body unless you have been melting it etc? If it wasn't solid it would burn you if you got it on your skin. You can only inhale vapours not a metal. If you ate it then it would probably damage or clog up your insides otherwise just pass out in a stool, depends how much you ate. People eat from aluminium and touch it every day so it is not dangerous to be in contact with.

- Q: What is the role of aluminum coils in HVAC systems?

- The functioning of HVAC systems relies heavily on the presence of aluminum coils, which are vital for system efficiency. Within the air conditioning unit, aluminum coils serve as a crucial component responsible for the transfer of heat between indoor and outdoor environments. When the air conditioning unit operates in cooling mode, the aluminum coils serve as evaporator coils. Their primary function is to absorb heat from the indoor air, resulting in its cooling. The warm air from the room passes over the cold aluminum coils, and the heat is then transferred to the refrigerant flowing through the coils. This process effectively cools the air while removing moisture, ultimately achieving the desired cooling effect. In heating mode, the aluminum coils take on the role of condenser coils. They receive the hot refrigerant from the compressor and proceed to transfer the heat to the surrounding air. This hot air is then circulated throughout the building, providing warmth during colder weather. Aluminum coils are preferred in HVAC systems due to their exceptional heat transfer properties and resistance to corrosion. These coils are lightweight, durable, and possess high thermal conductivity, enabling efficient heat exchange. Additionally, aluminum coils are more environmentally friendly compared to other materials like copper, as they are easier to recycle. Regular maintenance and cleaning of the aluminum coils are essential to ensure optimal performance and prevent any potential airflow restrictions caused by the accumulation of dust, dirt, or debris. Neglecting coil maintenance can result in reduced cooling or heating capacity, decreased energy efficiency, and even system breakdowns. Overall, the significance of aluminum coils in HVAC systems cannot be overstated. These coils play a vital role in facilitating the heat transfer process, enabling efficient temperature control in both cooling and heating modes, and contributing to the overall comfort and functionality of the system.

- Q: How are aluminum coils used in the production of aircraft components?

- Aluminum coils play a vital role in the manufacturing of aircraft components, offering a combination of strength, durability, and lightness that makes them ideal for this purpose. One primary application of aluminum coils in aircraft production involves fabricating sheet metal parts. Through techniques like rolling, stretching, and bending, these coils are transformed into flat sheets of aluminum, which are then cut and shaped to create wings, fuselage panels, and tail surfaces. The lightweight nature of aluminum makes it a preferred material for aircraft construction, as it reduces the overall weight of the aircraft and improves fuel efficiency and performance. Using aluminum coils allows manufacturers to easily produce thin and lightweight parts, contributing to the overall weight reduction of the aircraft. Additionally, aluminum coils are utilized in the production of structural components such as frames and beams. These coils are formed into extrusions, which are then cut and joined to create the structural elements of the aircraft. Aluminum's high strength-to-weight ratio makes it an excellent choice for these components, providing the necessary strength while keeping the aircraft's weight low. Apart from its structural applications, aluminum coils are also used in the production of various aircraft systems. For example, they are incorporated into the construction of heat exchangers, air conditioning units, and fuel tanks. Aluminum's excellent thermal conductivity allows for efficient heat transfer, which is essential for maintaining optimal operating conditions within the aircraft. Overall, aluminum coils are extensively utilized in the manufacture of aircraft components due to their lightweight nature, high strength, and excellent thermal properties. Their versatility and the ability to be processed into different shapes and sizes make them the preferred material for manufacturing critical aircraft parts, ensuring the safety, performance, and efficiency of modern aircraft.

- Q: my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Well, you start with an aluminum rich rock (cheaper to process). The raw ore after physical concentration (removal of secondary minerals) is reacted by an electrolytic process. This means that electricity is used to convert the aluminum ion in the raw rock into the metal aluminum. Sort of like the reverse of a battery, to keep things simple. Aluminum smelters tend to be set up in places with cheap electricity, because the process uses a LOT of electricity. That is why there are several up here in quebec, we have cheap hydro electricity and the government gives decent deals to the smelters on top of the already low market price. Do a search on aluminum smelting to find out more. Not sure what your level of knowledge is so not sure how much you will understand.

- Q: What are the storage life and shelf life of aluminum coils?

- The storage life and shelf life of aluminum coils can vary depending on various factors such as the type of alloy, coating, and storage conditions. However, in general, properly stored and maintained aluminum coils can have a storage life of several years and a shelf life of up to 12 months or more. It is important to store them in a dry, clean, and well-ventilated area to minimize the risk of corrosion or other damage. Regular inspection and maintenance are also crucial to ensure their longevity.

- Q: Is it possible to utilize aluminum coil as a conductor for speaker wires?

- <p>While it is technically possible to use aluminum coil as speaker wire, it is not recommended. Aluminum has higher resistance and lower conductivity compared to copper, which is the standard material for speaker wires. This can result in signal loss and reduced sound quality. Copper is preferred due to its superior electrical conductivity, ensuring minimal signal degradation over distance. For optimal audio performance, it's best to use speaker wire made from high-quality copper or copper-clad aluminum.</p>

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: Domestic production of color coated aluminum coil manufacturers which good?

- It is widely used in the field of architectural decoration, such as aluminum ceiling, aluminum plate and so on. There are many manufacturers of color coated aluminum rolls, big and small.

- Q: Is it possible to utilize an aluminum coil as a light source?

- <p>Aluminum coil itself cannot be used as a light source. Aluminum is a good conductor of electricity but does not emit light when electrified like certain materials can. To create light, materials like tungsten in incandescent bulbs or phosphors in fluorescent lights are used. Aluminum coils can, however, be used in conjunction with other components in lighting fixtures, such as in heat sinks to dissipate heat from LEDs, but they do not produce light directly.</p>

Send your message to us

026 Aluminum Coil - 6083 T5 Aluminum Alloy Plate/Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 90000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords