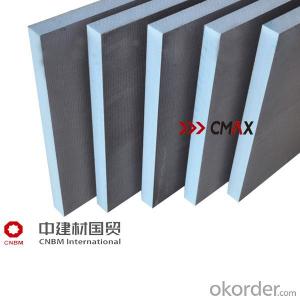

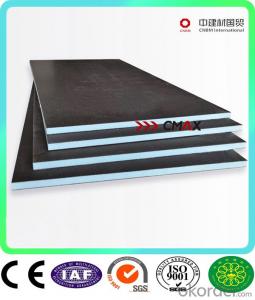

XPS Board Lowes White Extruded Polystyrene Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | TYXPS | Color: | pink or blue | Compressive strength: | >250Kpa |

| Apparent Density: | 35~40kg/m3 | Heat Conductivity: | 0.027~0.030 | Highest Working Temperature: | 75 centidegree |

| Water absorption: | <=1.00% | Coefficient of linear thermal expansion: | 0.07 |

Packaging & Delivery

| Packaging Detail: | plastic bag |

| Delivery Detail: | 7 days after deposit |

Specifications

White extruded polystyrene board

1. HCFC and CFC free

2. Length<=6000mm

3. Thickness:4~120mm

4. CE approved

White extruded polystyrene board (CE)

Product Description

XPS foam board is an extruded polystyrene insulation manufactured through a plastic extrusion process. The resulting boards are almost 100% closed cell, strong, highly moisture resistant and easy to cut and shape.

XPS foam board widely used in wall insulation, low-temperature storage facilities, parking platform, the airport runway, construction of concrete roof and the structure of the roof, highways and other areas of moisture-proof inexpensive decoration industry Material.

Characteristics:

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape.

Recyclable: Polyfoam can be 100% recycled

Available Sizes:

Length | Width | thickness |

no limitation could be cut according to design | 600mm 900mm 1200mm | 20~100mm |

Other thickness as 4mm~10mm, could be cut from thicker panel

Technical Data:

Density | Kg/m3 | 35~45 |

Thermal conductivity, 90 days, 10°C | W/mK | 0.027~0.036 |

Compressive strength at 10% deflection or yield, (vertical) | kPa | 250~700 |

Tensile strength | kPa | ≥350 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | mm/mK | 0.07 |

Temperature limits | °C | -50°C, +75°C |

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- 2 fastener type steel pipe stent construction must be prepared before the construction program

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q: Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- The cast iron pipe is the old type of hand-cast iron pipe, which is a non-flexible pipe

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The First play expansion bolts, do insulation, can say the details of the point. There is that you can use .7 inside the expansion of the screw, to Fu Fu Huang Peng, You can also use welding, then a long screw, is also very simple.

- Q: How to distinguish between good and bad insulation board insulation board

- Your main source of high temperature in the room is the west of the glass and the south of the window you can in the west and south from the glass 20_50 cm hanging curtains so much of the heat was blocked the roof available 60 * 60 gypsum board ceiling that Economic effect and good ceiling 15-18 yuan per square

Send your message to us

XPS Board Lowes White Extruded Polystyrene Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords