Rigid Xps Foam Board - White Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | X350 | Thickness: | 10-120mm | Color: | White / Light yellow / Blue /Green /Pink |

| Density: | 28-55 kg/m3 | Width: | 600mm / 900mm / 1200mm | Length: | 1200mm-3000mm(or any) |

| Marketing Name: | White Extruded Polystyrene Board | Surface: | Withskin / Roughing / Embossing | Edge Shape: | SL SS T&G |

Packaging & Delivery

| Packaging Detail: | Plastic Bag Packing,68.4M3/40'HQ,Customer Label offered. |

| Delivery Detail: | 15 days |

Specifications

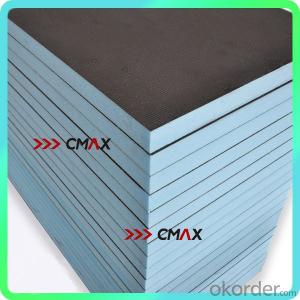

White Extruded Polystyrene Board

1.Thickness:10-120mm

2.Width:600-1200mm

3.Density:28-50Kg/m3

Product Description

Feininger White Extruded Polystyrene Board

XPS Extruded Polystyrene Foam Board Production Process: Polystyrene Granule, Talcum Powder, Masterbatch, Blowing Agent are mixed and melted in Extruder.The melt material will be extruded out of Slot Die, then through Calibrator, we reach a panel shape. After cooling, cutting, edge trimming, we will pack in water-proof plastic bag. This is the XPS Foam Board in market.

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendlyRecyclable: Polyfoam can be 100% recyclied

Technical data sheet of White Extruded Polystyrene Board

Density | Kg/m3 | 31~50 |

Thermal conductivity, 90 days, 10°C | W/mK | 0.027~0.03 |

Compressive strength at 10% deflection or yield, (vertical) | kPa | ≥250 |

Tensile strength | kPa | ≥250 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | mm/mK | 0.07 |

Temperature limits | °C | -50°C, +75°C |

Packaging & Shipping

Feininger White Extruded Polystyrene Board

Plastic Bag Packing

68.4M3/40HQ

Container Loading

Size Length (mm) | Pcs/Pack | M2/Pack |

1200*600*50 | 10 | 7.2 |

2400*600*50 | 10 | 14.4 |

2440*600*50 | 10 | 14.64 |

2500*600*50 | 9 | 13.5 |

Our Services

Manufacture brand-new Feininger White Extruded Polystyrene Board

Carry out on-line quality supervision and test the insulation material before shipping

Pack XPS Foam in plastic bag

Issue Test Report

Ship the material by full container load

Make arrangement of transportation

Instruct how the XPS Foam Board is applied.

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Brothers asked, what is the price of extruded board in 2008 to do a report need to trouble to tell the next thank you

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- The bar spacing is called 'step distance', 1.2 ~ 1..1.8m, no minimum spacing, maximum 1.8m. Pole spacing 1..1..1.55m, no minimum spacing, maximum 1.55m. See JGJ130 Haifa Fenzhuang Curcuma Gufeng Koufukai -2011 "Construction Construction Fastener Steel Scaffolding Safety Technical Specification" 'Structural Requirements'.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Generally in the 100-300 yuan / cubic or so, 60 mm thick is 6-18 yuan / square or so Specifically look at how much you use the density of the Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheated in the mold after heating the formation of white objects, its fine The structure of the obturator is mainly used for building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, widely

Send your message to us

Rigid Xps Foam Board - White Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords