WS ER70S-6 CO2 Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

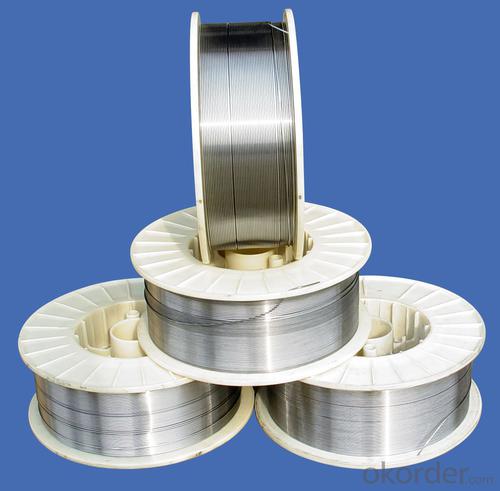

WS ER70S-6 CO2 Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

Main Structure of Gas Shielded Welding Wire

welding wire

1.professional manufacturer and exporter

2.ISO,SGS,CE approved

3.free sample, prompt delivery, global customers

4.Shield gas : CO2

5.Material:Carbon steel

6.Package:15kgs-20kgs/spool, 100kg-250kgs/barrel

7.Application:Current range (A) 0.8mm 40-140

8.Lead time:20-30 days after receiving L/C or Pre-paid

Advantages of Gas Shielded Welding Wire

1. Type: CO2 wire/SG2 welding wire/ Mig wire/ Copper coated welding wire/Solid welding wire/ Gas shielded welding wire

2. Raw material: MIld steel/ Carbon steel/ Qingdao steel wire

3. Surface--- Copper coated

4. Application : Co2 shielded welding, welding of mild steel material,

5.Diameter:0.8mm-1.6mm

6.Flux content: without flux

Datas and Information for Gas Shielded Welding Wire

Welding wire chemical compositions % :

Mark | Confirm with | Chemical composition, % | |||||||||

ER50-6 |

AWS ER70S-6 | C | Mn | Si | P | S | Ni | Cr | Cu | Mo | V |

0.08 | 1.51 | 0.89 | 0.015 | 0.013 | 0.016 | 0.021 | 0.18 | 0.006 | 0.003 | ||

Mechanical properties of welding wires:

Mechanical properties of weld metal | Normative |

Tensile strength, MPa | 545 |

Yield strength, MPa | 452 |

Elongation ratio, % | 29 |

Impact toughness, J | 91(-30°C) |

Pictures:

- Q: Can stainless steel wire be used for automotive springs?

- Yes, stainless steel wire can be used for automotive springs. Stainless steel has excellent corrosion resistance and high tensile strength, making it a suitable material for springs that are exposed to harsh environments or require high durability.

- Q: Stainless steel how to make copper imitation drawing effect?

- First stainless steel wire drawing, and then handed over to an electroplating factory to deal with it.

- Q: What type of argon arc welding wire is used in 1Cr13 stainless steel?

- Argon arc welding generally uses H0Cr14 or H1Cr13. Sometimes austenitic steel wires are also selected to improve weldability.1Cr13+Q235B belongs to dissimilar steel welding, H0Cr20Ni10 welding wire is usually used.

- Q: What are the different types of stainless steel wire rope pulleys?

- Various industries commonly utilize several different types of stainless steel wire rope pulleys. 1. Single Sheave Pulleys: These pulleys have one rotating wheel or sheave on an axle. They are suitable for simple lifting and pulling tasks that require only one line of wire rope. 2. Double Sheave Pulleys: These pulleys have two wheels or sheaves rotating on a shared axle. They evenly distribute the load between two wire rope lines, making them ideal for applications that require increased lifting capacity or balance. 3. Swivel Eye Pulleys: These pulleys have a swivel eye attachment, allowing them to freely rotate in any direction. They are particularly useful when the pulley needs to change direction or follow the load's movement. 4. Fixed Eye Pulleys: These pulleys have a fixed eye attachment and cannot rotate freely. They are commonly used when the load's direction remains constant and no rotation is necessary. 5. Adjustable Pulleys: These pulleys have a mechanism that enables the adjustment of the distance between the sheaves. This feature is beneficial in applications where the wire rope's length needs to be modified to accommodate different loads or lifting heights. 6. Heavy-Duty Pulleys: These pulleys are specifically designed to handle heavier loads. They are constructed with larger sheaves and stronger materials, making them suitable for demanding industries like construction, mining, and marine. 7. Stainless Steel Swivel Pulleys: These pulleys are made from stainless steel, offering excellent corrosion resistance and durability. They are commonly used in outdoor or marine environments where exposure to moisture or saltwater can cause rust or degradation. Ultimately, the selection of a stainless steel wire rope pulley depends on the specific application requirements, load capacity, and environmental conditions in which it will be utilized.

- Q: The difference between high gloss wire drawing and stainless steel drawing panel

- High light refers to stainless steel, stainless steel surface fineness reflective processing, and of course materials and postprocessing are involved, the simple point is like a mirror or silver surface like stainless steel, used for decoration, luxury door handrails, etc.,

- Q: How are stainless steel wire cables used in construction?

- Due to their exceptional strength, durability, and versatility, stainless steel wire cables are crucial components in construction projects. They serve various purposes, including providing structural support, enhancing safety, and enabling efficient construction practices. Suspension systems in construction heavily rely on stainless steel wire cables. These cables are commonly used to suspend different building elements like ceilings, bridge decks, and canopies. With their high tensile strength, they can bear heavy loads and offer the necessary support to ensure the stability and integrity of these structures. Stainless steel wire cables are also utilized in bridge construction as stay cables. These cables help balance the weight of the bridge deck, preventing excessive deflection and ensuring overall stability. They are also employed in the construction of cable-stayed bridges, arranged in a fan-like pattern to support the bridge deck from multiple points. In high-rise buildings, stainless steel wire cables serve as guy wires or guyed masts. They provide additional support to tall structures, particularly in areas prone to strong winds or earthquakes. By anchoring the building to the ground or other stable structures, the cables minimize swaying and ensure occupant safety. Furthermore, stainless steel wire cables are used for safety purposes in construction. They act as fall protection systems, serving as lifelines or safety nets to prevent workers from falling from heights. These cables are typically installed along building edges or scaffolding, ensuring worker safety during construction and maintenance activities. Stainless steel wire cables also serve functional purposes in construction projects. They are employed in the installation of curtain walls, supporting glass panels and enhancing the aesthetic appeal of buildings. These cables are also utilized in the construction of tension structures like canopies and awnings, enabling large spans and minimal support points due to their high strength. To summarize, stainless steel wire cables are essential in construction, providing structural support, enhancing safety, and enabling innovative design solutions. Their strength, durability, and versatility make them indispensable in a wide range of construction applications, ensuring the stability, functionality, and safety of buildings and structures.

- Q: What are the different types of stainless steel wire hooks?

- There are several different types of stainless steel wire hooks available, each designed for specific uses and applications. Some of the common types include: 1. S-shaped hooks: These hooks have a distinctive S shape and are commonly used for hanging lightweight items such as kitchen utensils, plants, or tools. They are easy to install and provide a secure hanging solution. 2. J-shaped hooks: J-shaped hooks are similar to S-shaped ones but have a straight bottom section and a curved hook at the top. They are commonly used for hanging larger and heavier items such as bicycles, ladders, or garden equipment. 3. Eye hooks: Eye hooks feature a circular or oval-shaped eye at one end, allowing them to be easily attached to ropes, chains, or cables. They are commonly used in rigging applications, hanging signs, or suspending objects from above. 4. Cup hooks: Cup hooks have a small cup-shaped base with a curved hook extending from it. They are often used for hanging lightweight items such as mugs, keys, or small decorations. Cup hooks can be easily screwed into walls or other surfaces. 5. Ladder hooks: Ladder hooks are specifically designed for hanging ladders securely. They are typically made of heavy-duty stainless steel and feature a wide hook that can accommodate the width of a ladder's rungs. These hooks are commonly used in garages, workshops, or storage areas. 6. Ceiling hooks: As the name suggests, ceiling hooks are designed to be mounted on ceilings. They are often used for hanging plants, light fixtures, or decorative items. Ceiling hooks are available in various sizes and styles to accommodate different weights and design preferences. 7. Utility hooks: Utility hooks are versatile hooks that can be used for a wide range of purposes. They typically have a simple design with a straight or curved hook and are commonly used for organizing tools, hanging coats, or storing equipment. It's important to choose the right type of stainless steel wire hook based on the weight and purpose of the item you want to hang. Additionally, ensure that the hook is made of high-quality stainless steel to maximize durability and corrosion resistance.

- Q: Can stainless steel wire be used for aerospace applications?

- Yes, stainless steel wire can be used for aerospace applications. Stainless steel has excellent corrosion resistance, high strength, and good heat resistance, making it suitable for various components and structures in aerospace engineering, such as aircraft frames, engine parts, and wiring systems.

- Q: Can stainless steel wire be used for wire baskets or trays?

- Yes, stainless steel wire can be used for wire baskets or trays. Stainless steel wire is known for its strength, durability, and corrosion resistance, making it an ideal material for various applications including wire baskets and trays. The high tensile strength of stainless steel wire ensures that the baskets or trays can safely hold and support heavy items without bending or breaking. Additionally, the corrosion resistance of stainless steel prevents rusting, allowing the wire baskets or trays to be used in environments where moisture or chemicals may be present. The smooth surface of stainless steel wire also makes it easy to clean and maintain, ensuring hygiene and preventing the buildup of dirt or bacteria. Overall, stainless steel wire is a reliable and practical choice for wire baskets or trays.

- Q: Can stainless steel wire be used for wire rope swivels?

- Yes, stainless steel wire can be used for wire rope swivels. Stainless steel is a popular material choice for wire rope swivels due to its excellent corrosion resistance, high strength, and durability. It can withstand harsh environments and is resistant to rust and corrosion, making it suitable for outdoor and marine applications. Additionally, stainless steel wire offers good flexibility and tensile strength, ensuring reliable performance and ease of use. Overall, stainless steel wire is a reliable and suitable choice for wire rope swivels.

Send your message to us

WS ER70S-6 CO2 Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords