Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

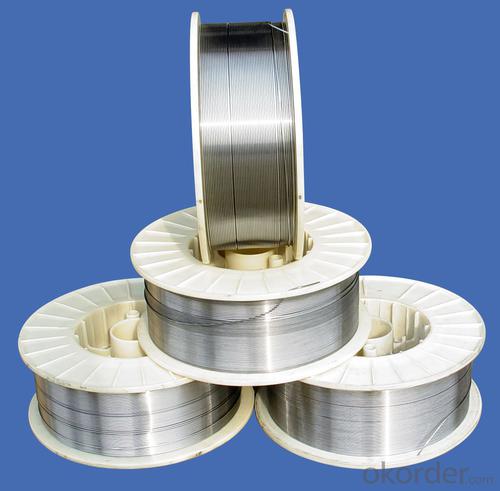

Gas Shielded Welding Wire 1.2mm With MSDS, CE, SGS, ISO9001

Structure of Gas Sheilded Welding Wire

1.ISO,SGS,CE approved

2.free sample, prompt delivery, global customers

3.Shield gas : CO2

4.Material:Carbon steel

5.Package:15kgs-20kgs/spool, 100kg-250kgs/barrel

6.Application:Current range (A) 0.8mm 40-140

7.Lead time:20-30 days after receiving L/C or Pre-paid

Main Features of Gas Sheilded Welding Wire

1. Type: CO2 wire/SG2 welding wire/ Mig wire/ Copper coated welding wire/Solid welding wire/ Gas shielded welding wire

2. Raw material: MIld steel/ Carbon steel

3. Surface--- Copper coated

4. Application : Co2 shielded welding, welding of mild steel material,

5.Diameter:0.8mm-1.6mm

6.Flux content: without flux

Datas Information of Sheilded Welding Wire

Welding wire chemical compositions % :

Mark | Confirm with | Chemical composition, % | |||||||||

ER50-6 |

AWS ER70S-6 | C | Mn | Si | P | S | Ni | Cr | Cu | Mo | V |

0.08 | 1.51 | 0.89 | 0.015 | 0.013 | 0.016 | 0.021 | 0.18 | 0.006 | 0.003 | ||

Mechanical properties of weld metal | Normative |

Tensile strength, MPa | 545 |

Yield strength, MPa | 452 |

Elongation ratio, % | 29 |

Impact toughness, J | 91(-30°C) |

FAQ of Gas Sheilded Welding Wire

Q: How about the quality about your products?

A:We are manufacturer strictly according to national and international standard, and we take a test on every pipe before delivered out. If you want to see our quality certifications and all kinds of testing report, please just ask us for it.

Pictures:

- Q: The use of stainless steel side silk

- I'll show you a way out. It's definitely a good prospect: you're not asking too much!For stainless steel chain mills, they usually buy billets, which are rolled to a specific width to improve utilization. If your width is right and the price is good, the two companies can cooperate for a long time.

- Q: What are the different types of stainless steel wire rope?

- There are several types of stainless steel wire rope, including 1x19, 7x7, and 7x19 constructions. The 1x19 is a rigid and strong rope, suitable for structural and architectural applications. The 7x7 is more flexible and commonly used for general-purpose applications such as cable railing and garage doors. The 7x19 is the most flexible and commonly used for lifting and rigging applications due to its higher strength and resistance to fatigue.

- Q: How does stainless steel wire resist corrosion?

- Stainless steel wire resists corrosion due to its unique composition and surface properties. It is primarily made up of iron, chromium, and nickel, with other elements such as molybdenum, titanium, and copper added in varying amounts to enhance specific properties. The key to stainless steel's corrosion resistance lies in the presence of chromium. Chromium forms a thin, protective oxide layer on the surface of the wire when exposed to oxygen in the atmosphere. This layer, known as passive film or chromium oxide, acts as a barrier, preventing oxygen and moisture from reaching the underlying metal. It effectively isolates the wire from the external environment, reducing the chance of corrosion. Moreover, the chromium oxide layer is self-healing. If it gets damaged or disrupted, it quickly reforms when exposed to oxygen, restoring the wire's corrosion resistance. This self-healing property makes stainless steel wire highly durable and long-lasting. The addition of nickel further enhances the corrosion resistance of stainless steel wire. Nickel helps stabilize the passive film and improves its ability to withstand corrosive agents, such as acids and chlorides. It also helps the wire maintain its strength and ductility even in extreme conditions. The specific grade of stainless steel wire chosen also affects its corrosion resistance. Different grades have varying amounts of chromium, nickel, and other alloying elements, making them suitable for specific applications. For example, marine-grade stainless steel wire, such as 316 stainless steel, contains higher amounts of molybdenum, which enhances its resistance to chloride-induced pitting and crevice corrosion in marine environments. In summary, stainless steel wire resists corrosion by forming a protective chromium oxide layer on its surface, which acts as a barrier against oxygen and moisture. The addition of other alloying elements, such as nickel and molybdenum, further enhances its resistance to corrosive agents. This unique composition and surface properties make stainless steel wire an excellent choice for various applications where corrosion resistance is crucial.

- Q: Why does the stainless steel hydrogen return wire rust?

- Stainless steel wire hydrogen back surface adhesion of inorganic juice (such as vegetables, soup, sputum), oxygen in the water condition, composition of inorganic acid, inorganic acid on the metal surface.

- Q: What are the different diameters available for stainless steel wire?

- There are several different diameters available for stainless steel wire, ranging from very thin to thicker options. The specific diameters can vary depending on the manufacturer and the intended use of the wire. Common diameter options for stainless steel wire include 0.02mm, 0.05mm, 0.1mm, 0.2mm, 0.5mm, 1mm, and larger. These diameters are typically measured in millimeters or sometimes in gauge sizes. It is important to choose the appropriate diameter based on the specific application requirements, such as strength, flexibility, or conductivity.

- Q: What are the common uses of stainless steel wire in the oil and gas industry?

- Stainless steel wire is commonly used in the oil and gas industry for various applications such as wireline operations, downhole tools, and control lines. It is used for its high strength, corrosion resistance, and ability to withstand harsh environments. Stainless steel wire is employed in wireline operations for tasks like measuring wellbore parameters, setting and retrieving tools, and conducting well interventions. Additionally, it is utilized in downhole tools such as fishing tools, packers, and plugs due to its durability and resistance to corrosive substances. Control lines made of stainless steel wire are used to transmit signals and fluids in well control systems, ensuring efficient and reliable operations in the oil and gas industry.

- Q: How does stainless steel wire differ from regular steel wire?

- There are several ways in which stainless steel wire differs from regular steel wire. Firstly, stainless steel wire is manufactured using an alloy that contains a high percentage of chromium, resulting in its corrosion-resistant properties. This implies that stainless steel wire has a higher resistance to rust and oxidation compared to regular steel wire. Moreover, stainless steel wire possesses a greater tensile strength, meaning it is more robust and able to withstand higher forces before breaking or deforming. This renders stainless steel wire suitable for applications that demand a high level of strength and durability. Furthermore, stainless steel wire exhibits a bright and shiny appearance, which is often sought after in decorative or aesthetic applications. Conversely, regular steel wire may have a duller appearance and is frequently utilized for industrial or structural purposes. In conclusion, the primary distinctions between stainless steel wire and regular steel wire lie in their corrosion resistance, strength, and appearance. Stainless steel wire proves to be a superior choice for applications that necessitate resistance to rust, enhanced strength, and an appealing finish.

- Q: Does stainless steel wire require any special tools for handling?

- Yes, stainless steel wire does require special tools for handling. Due to its strength and durability, stainless steel wire cannot be easily cut or manipulated with regular tools. Specialized tools such as wire cutters, pliers, and crimpers are necessary to handle stainless steel wire effectively. These tools are designed to provide a secure grip and ensure clean and precise cuts without damaging the wire. Additionally, special tools may be required for bending, shaping, and attaching stainless steel wire to various structures or objects. It is important to use the appropriate tools to handle stainless steel wire to ensure safety and achieve desired results.

- Q: How to make clothes hanger for 4 mm 304 stainless steel wire

- Stainless steel is a metallic material, stainless steel (Stainless, Steel) refers to air, steam, water and other weak corrosive medium and acid, alkali, salt and other chemical corrosive medium corrosion of steelAlso called stainless acid resistant steel

- Q: Can stainless steel wire be used for filtration applications?

- Indeed, filtration applications can utilize stainless steel wire. This material, known for its durability and resistance to corrosion, proves highly suitable for diverse filtration procedures. Particularly in industrial environments, stainless steel wire is commonly employed to filter liquids, gases, and particles. To attain desired filtration efficiency, the wire can be woven into various mesh sizes and shapes. Furthermore, it is possible to enhance the wire's filtration properties by coating or treating it with different substances, thereby improving its resistance to high temperatures or chemical reactions. Ultimately, stainless steel wire serves as a versatile solution capable of effectively meeting the filtration requirements of various industries.

Send your message to us

Gas Shielded Welding Wire 1.2mm with MSDS, CE, SGS, ISO9001

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords