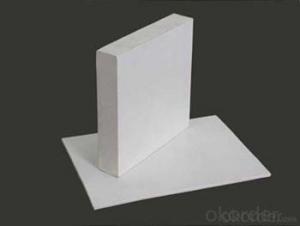

Plastic Sheets - WPC Foam Board for Shuttering of Roof Slabs in Building Construction, PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Detailed specifications:

Thickness 1-33mm

Width 1220mm, 1560mm, 2050mm

Length As requirement

Color: white,black etc.

We also can manufacture according to your requirement.

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

Advantage:

1. Waterproof, Moisture/Water resistant, less rotten, proven under salt water condition, UV-resistance

2. Fire retardant and self-extinguishing

3. Sound-insulated; Non-toxic

4. High recyclable, eco-friendly, saving forest resources

5. Weather resistant, suitable from minus -30 to 70 centigrade degree

6. Well done of Termites, insects, and moldy-proof

7. Easy to nail, hammered, drilled, sawed, turned, glued, bended, printed, oiled, thermoforming

8. Easy to clean

9. No any benzene and the formaldehyde discharge,Non-toxic

FAQ:

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.

Q: What factors affect the price?

A: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to get exact quotation.

- Q: Are plastic sheets resistant to high-pressure applications?

- Yes, plastic sheets can be resistant to high-pressure applications depending on the specific type of plastic used and its thickness. Certain plastics, such as polycarbonate or acrylic, have excellent strength properties and can withstand high-pressure conditions without deforming or breaking. However, it is important to consider the specific requirements of the application and consult with manufacturers or experts to ensure the chosen plastic sheet is suitable for the intended high-pressure environment.

- Q: looking for felxiable mirorred plastic no more than a 1/2 inch ..that i can order online or go to a store in portland oregon and buy in 3 ft sections making a wearable design.. in sliver and gold or black ... any help where to get this would help.. Thanks

- I believe Mylar like balloons are made from is the material you are looking for You can buy it on line or from hydrophonic stores.

- Q: Are plastic sheets resistant to chemicals used in agriculture?

- Yes, plastic sheets are generally resistant to the chemicals used in agriculture.

- Q: are pvc plastic sheets and acetate sheets made from the same or similar things?

- they are different. acetate can be transparent like glass and isn't very flexible. I haven't seen clear PVC (thats not to say it doesn't exist) but it can be very flexible- like garbage bags or it can be made hard - like plastic pipes. PVC is more a group of plastics

- Q: I have a 30 gallon plastic bucket that I cut a large square out of it and I have molded the acrylic sheet to the right shape, but is there anyway I can bond the acrylic to the plastic? It needs to be water proof and not leech any chemicals. It will be filled up with water and will hold some fish.

- I can't answer your question. First of all, acrylic sheet IS plastic. There are many different types of plastic and bonding agents vary with each one. Furthermore, certain plastics do not bond well together. You need to go to a plastic supplier and let them know what your plastic bucket is made of. Or, if you take it with you, they should be able to tell and recommend the correct adhesive for you. I doubt that Home Depot or Lowes would be able to help you, but you can give them a try.

- Q: I had to put a plastic sheet over my garden because it has been raining non-stop. When the sun comes out, will I have to take it down, or will the UV rays pass thru it??

- SherylU, Ultraviolet rays will penetrate the plastic sheet.

- Q: Can plastic sheets be used for safety guards in manufacturing?

- Yes, plastic sheets can be used for safety guards in manufacturing. They are often used as a protective barrier to prevent accidents and injuries by providing a clear and durable separation between workers and potentially hazardous machinery or processes.

- Q: Perforate a sheet of plastic with a laser

- You want to punch in the workpiece do not burn workpieces, must use high power CO2 laser machine, on the workpiece marking speed, that is to say at a certain point of the workpiece energy will stay a short time, you can do not burn plastic.

- Q: I had a plastic bag in which bed sheets came and it disintegrated in my closet. How could this happen?

- There are some plastic bags that will dissolve in water. I suppose if the air in your closet were humid enough, over time the bag could dissolve. I know these bags are used in institutional laundries like those in hospitals and nursing homes, but it doesn't seem likely that they would be used for retail if they could dissolve that easily.

- Q: When you lifted the grey paper off the cardboard backing it erased what you wrote/draw. Anybody have any clue what those were called?

- OH YEAHHH They don't have a specific name I think.

Send your message to us

Plastic Sheets - WPC Foam Board for Shuttering of Roof Slabs in Building Construction, PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords