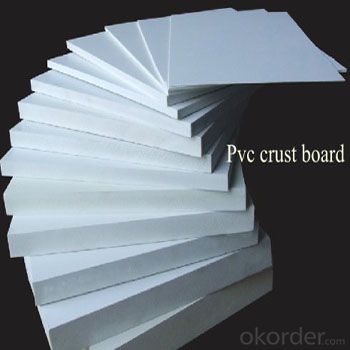

Plastic Sheets - WPC Foam Board / PVC Foam Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC foam sheet for advertising/ diplay /furniture/ cutting boards

The magnetic white board has a glossy surface that allows both smooth writing and easy cleaning,and it is made from high quality PET. The total number of writing and erasing could reach up to 100,000 times, and you can drop-wipe words and images easily even after 1 month!

Convenient Installation

1.For whiteboards with ferrous surface, our magnetic whiteboard sheet could be attached directly.

2.For whiteboards with magnetic surface, our ferrous whiteboard sheet could be attached directly.

3.For whiteboards with other surfaces, please glue our adhesive backed rubber magnet to the whiteboard surface first,and then stick our ferrous sheet to the rubber magnet.Or you can use removable whiteboard sheet directly.In addition, the rubber magnet is a permanent magnetic material that allows long-term use.

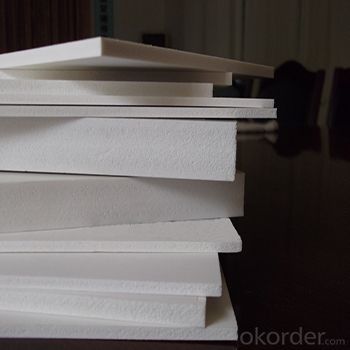

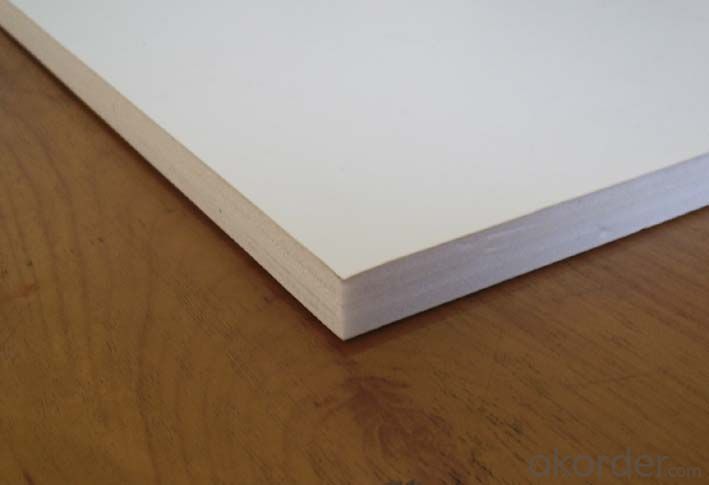

PVC Foam Board Features:

1. Light weight,good tenacity, high rigidity

2. Fireproof and flame resistant

3. Good insulation

4. No sopping, no deformation

5. Easily to processed

6. Good plasticity, being an excellent thermoform material

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. With imported dyes, unfading and anti-aging

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q: Can plastic sheets be used for insulation purposes?

- Yes, plastic sheets can be used for insulation purposes. They are commonly used as vapor barriers and thermal insulation in buildings to reduce heat transfer and prevent moisture infiltration. Plastic sheets with insulating properties, such as polyethylene or polystyrene, are effective in minimizing energy loss and improving thermal efficiency.

- Q: What are the different textures available for plastic sheets?

- There are several different textures available for plastic sheets, including smooth, matte, glossy, embossed, and textured.

- Q: Are plastic sheets suitable for electrical insulation?

- Yes, plastic sheets are suitable for electrical insulation. They are widely used in various electrical applications due to their non-conductive properties, high dielectric strength, and durability. Plastic sheets provide a barrier against electrical current, preventing the risk of electrical shocks and short circuits. They also offer resistance to moisture, chemicals, and temperature fluctuations, making them an ideal choice for insulating electrical components and wiring.

- Q: how do we make a transparent plastic sheet translucent?or vice versa

- My only guess is to heat it until the plastic thins enough to become translucent. Of course i have no clue how you might go the other way with it.

- Q: I need a piece of flat sturdy plastic about 1/8 thick. Does anybody know where I can buy this? I dont want plexiglass, its too expensive.

- places that sell glass/mirrors, etc usually have acrylic that they can cut for u

- Q: Can plastic sheets be used for protective barriers against COVID-19?

- Yes, plastic sheets can be used as protective barriers against COVID-19. They can help to create physical barriers and reduce the risk of transmission by blocking respiratory droplets and providing a layer of protection between individuals.

- Q: Can plastic sheets be used for interior design purposes?

- Yes, plastic sheets can be used for interior design purposes. They are versatile and can be utilized for various applications such as wall coverings, partitions, furniture, and decorative elements. Additionally, plastic sheets come in different colors, textures, and finishes, allowing for creativity and customization in interior design projects.

- Q: Are plastic sheets resistant to warping or bending over time?

- Yes, plastic sheets are generally resistant to warping or bending over time, especially if they are made from durable materials such as polycarbonate or acrylic. However, the level of resistance may vary depending on the thickness and quality of the plastic sheet.

- Q: Can plastic sheets be used for picture frames?

- Yes, plastic sheets can be used for picture frames. They are a commonly used material for framing due to their lightweight, affordable, and durable nature.

- Q: What are the thermal conductivity properties of plastic sheets?

- The thermal conductivity properties of plastic sheets are relatively low compared to other materials such as metals. This means that plastic sheets are generally good insulators and tend to have poor heat transfer capabilities. However, the thermal conductivity of plastic sheets can vary depending on the specific type of plastic used and its composition.

Send your message to us

Plastic Sheets - WPC Foam Board / PVC Foam Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords