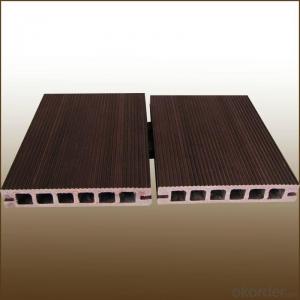

wpc decking / high density HDPE wood plastic composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Do you need to install a wooden floor? Do not have any harm

- Composite floor OKorder Geng high international 薨 huan arm for the force now do not need to install wood Leng. Now the solid wood composite flooring and laminate flooring are not wood Leng, the high practice is to lay the big core board base.

- Q: Are there any formaldehyde on the composite floor?

- In the composite wood floor, due to residual formaldehyde that does not participate in the reaction, it will gradually release to the surrounding environment in gaseous form. When people are in a high concentration of formaldehyde, the eyes, the nasal cavity and the breath Excitement will occur discomfort, harm to health.

- Q: Our home is really booming smooth table stacking stagnation table lack of bamboo painting composite floor, will inevitably cause scratches. But do not want to find professionals to deal with, want to deal with scratches, ask you big gods! The thank! The More

- Tip: home if it is heating film heating, please buy the floor, to the business needs, floor cover, cover the expansion joints, or very difficult to see, and will be difficult to take care of dust. Do not affect the beauty do not have to ignore it If the scratches are particularly large, you use the glass glue + nail polish (in line with the color of the floor) to reconcile the two together. And then applied to the floor. Try it out

- Q: How should the natural composite floor be maintained?

- How should the natural composite floor be maintained?

- Q: Strengthen the composite floor maintenance, how to maintain? To be detailed!

- Strengthen the composite floor maintenance, how to maintain? To be detailed!

- Q: Fancy a composite floor above the standard: home 2 level. Ask the business is what, he said refers to the wear resistance ≥ 6000 turn. Is it right? More

- According to the 2007 national standard, the home level is more than 4000 rpm ~ home, then 2 is enough ~ In addition, another business to buy it, he is not honest Ha ~

- Q: How to install the floor of the composite method

- Is the need for special tools.

- Q: We had bought some Virginia Millworks 1/2 thick hand scraped engineered nail down flooring for our kitchen. I had asked the guy at Lumber Liquidators where we bought it from if I needed to take the flooring out of the boxes to let it acclimate and he said no, that I could leave it in the boxes. When we got it home all we did was remove the plastic wraping from the boxes and then let the boxes sit side by side, not stacked, in the kitchen. We don't have a lot of space to leave the flooring out anyway. I then got sick for a while so everything sat in the kitchen as we left it for 3 weeks. I'm better and ready to lay it down this weekend but I just read that if I don't have a moisture meter to test the moisture content then I should lay the flooring out of the packaging for 7 days. Should I still do that or do you think having the flooring resting 3 weeks in unsealed cardboard boxes is fine? It's going down over a raised wooden sublfoor with red rosin paper, if it matters. Thanks in advance.

- You should be fine. Moisture testing is generally done for new construction since subflooring can be exposed to the weather and it will take a long time to dry properly.Unless of course your floor has been exposed to these conditions,which I don t think so..The only thing I would ve done was to open the boxes, but thats generally done when acclamating the wood for a 72 hr time frame.Rosin paper is fine.. As far as cleats or staples are concerned, that should be check w/ the manufacturer. Staples are now usually ok from the makers , but make sure 1st, you don t want to void your warranty. The length of the staple will be specified too. To drive staples there are 2 types of guns you can use.The stand up and drive them in or a special trigger type gun that you are on your knees and shoot them in. This is the method I prefer w/ the engineered wood since its easier to set the wood in place and staple. Don t forget a 10$ pair of knee pads. Any other questions you can e mail me thru my avatar GL

- Q: Solid wood composite flooring product quality

- Solid wood composite flooring product quality

- Q: How to install the wooden floor of the stairs?

- Stairs of the wooden floor of the installation method: According to the width of the stairs, the purchase of relatively wide format of the floor, strengthen, composite, solid wood can be. Strengthening and composite generally use floating installation, solid wood is used to play keel installation. Measuring the smoothness of the stairs, the error per meter more than 3mm need to first leveling treatment. Installation order from the bottom to the top, so the installation operation more smoothly and incidentally check the stairs floor of the pressure and normative. The first level of the staircase is the facade, so the floor expansion and expansion ratio should be taken into account when installing the floor floor. When the floor floor is installed to the elevation, the space between the facade floor and the floor floor should be kept enough space. The floor of the floor on the ground floor, you can carry out the next step to install the stairs floor. In the installation of flat flooring, the need to accurately measure the level of high correlation, to ensure that the measurement line and cutting the standard cut. The gap between the facade and the plane is not allowed to exceed 0.5mm; facade or plane and the wall, the gap between the skirting board is not allowed to exceed 1mm; floor and floor surface joints, strengthen the floor does not allow more than 0.2mm, solid wood flooring Allow more than 0.5mm.

Send your message to us

wpc decking / high density HDPE wood plastic composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches