Woven or Non Woven Geotextile Fabric of PP for Railway 270g/m2 Manufacture China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile of PP for Railway 270g/m2

Description Geotextile of PP for Railway 270g/m2

The permeable geotextile is a textile material of planar Structure used as an integral part in the placement of Gabion Baskets and mats.

It is a product made from Synthetic Fibers, non biodegradable, linked together by means of Thermal and Mechanical processes. Characterised by its structure and permeable, Great tensile strength, Tear and Chemical deterioration.

Features Geotextile of PP for Railway 270g/m2

good water absorption and permeability

high tensile strength

strong anti-deformation

Applications Geotextile of PP for Railway 270g/m2

dam

coastal beach for reinforcement

filtration

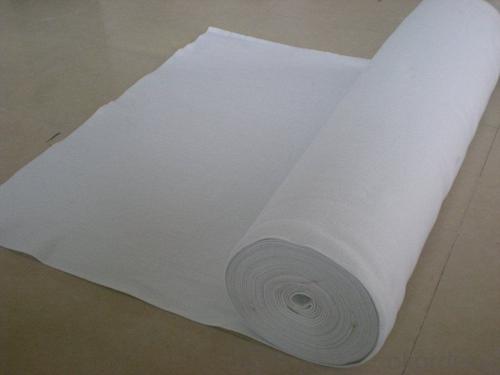

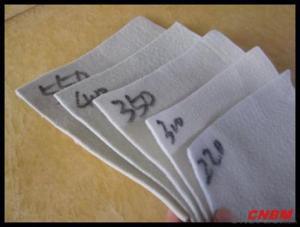

IMages of Geotextile of PP for Railway

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 14 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. They are often utilized for erosion control, soil stabilization, and drainage purposes in these projects. Geotextiles help to prevent soil erosion and provide a stable base for vegetation growth, making them a valuable tool in land reclamation efforts.

- Q: What are the geotextiles for concrete health

- Concrete health with the geotextile, I probably understand what you mean is planted in the above plant flowers and the like, it can be used Daxiang non-woven geotextile can, and hope to help you!

- Q: Are geotextiles resistant to UV radiation?

- Yes, geotextiles are typically designed to be resistant to UV radiation. They are often made from materials that have UV stabilizers or are treated with UV-resistant coatings, ensuring their durability and longevity when exposed to sunlight.

- Q: Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q: GB waterproof geotextile what price

- The price of Guobao waterproof geotextile is calculated according to the weight per square meter. For more information, please contact us.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing a strong and stable base for the asphalt layer. They prevent the mixing of different soil layers, distribute loads evenly, and increase the tensile strength of the pavement. Additionally, geotextiles help to reduce cracking, rutting, and other forms of pavement distress, resulting in a longer-lasting and more durable road surface.

- Q: What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, several factors should be considered. These include the strength and durability of the geotextile, its ability to withstand environmental conditions such as sunlight exposure and chemical degradation, its filtration and drainage properties, and its compatibility with the soil and other materials used in the embankment. Additionally, factors such as cost, installation requirements, and the specific project requirements and goals should also be taken into account.

- Q: Geotextile laying should be beyond the edge of how to set the number of specific requirements? Which specification is more detailed

- Can be more than 1 meter or so, I am specializing in the production of geotechnical materials, wish smooth

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a separate protective layer or as a reinforcement in geosynthetic clay liner caps to enhance their performance and provide additional benefits such as filtration, separation, and erosion control.

Send your message to us

Woven or Non Woven Geotextile Fabric of PP for Railway 270g/m2 Manufacture China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords