Woven Fiberglass Fabric Continuous Stand Mat 2024 - China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

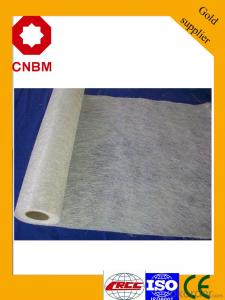

| Technique: | Chopped Strand Fiberglass Mat (CSM) | Dimensions: | 450gsm | Mat Type: | Continuous Filament Mat |

| Fiberglass Type: | E-Glass | Softness: | softness | Place of Origin: | Jiangxi, China (Mainland) |

| Brand Name: | cnbm | Model Number: | 450gsm | color: | white |

| fiberglass type: | E glass | product: | e-glass powder chopped stand mats | binder: | powder or emulsion |

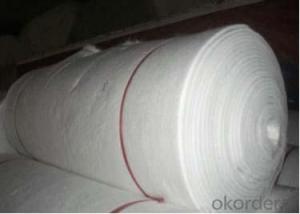

| width: | 1040 or 1270mm, as your requirement | weight: | 30 or 45kg/roll | paper tube diameter: | 90mm |

| outer diameter of roll: | 256mm | packing: | plastic film+carton box + pallet |

Packaging & Delivery

| Packaging Details: | plastic film+carton box + pallet |

| Delivery Detail: | 15-20days |

Specifications

1.e-glass powder chopped stand mats

2.binder:power or emulsion

3.width:1040mm or 1270mm

4.weight:450gsm

Picture

- Q: Is fiberglass fabric resistant to electrical conductivity?

- Yes, fiberglass fabric is resistant to electrical conductivity. Fiberglass is made from woven fibers of glass, which are non-conductive materials. This means that fiberglass fabric does not allow the flow of electrical current through it. It is commonly used in electrical insulation applications as it provides a protective barrier against electrical shocks and is an excellent insulator. The non-conductive nature of fiberglass fabric makes it a suitable choice for various electrical and electronic applications where the prevention of electrical conductivity is required.

- Q: What are the different fiberglass fabric weights for lightweight applications?

- There are several different fiberglass fabric weights available for lightweight applications. These weights are typically measured in ounces per square yard (oz/yd²) and range from very lightweight options to slightly heavier ones. One of the lightest options is a 3 oz/yd² fiberglass fabric, which is often used in applications where weight is a critical factor. This weight is suitable for applications such as aerospace components, lightweight structures, and automotive parts. Another commonly used weight for lightweight applications is the 4 oz/yd² fiberglass fabric. This weight provides a slightly higher level of strength and durability compared to the 3 oz/yd² fabric, while still remaining lightweight. It is often used in applications such as boat construction, sporting goods, and automotive body panels. For applications that require a bit more strength and rigidity, a 6 oz/yd² fiberglass fabric may be used. This weight is still relatively lightweight, but offers a higher level of reinforcement. It is commonly used in applications such as wind turbine blades, construction, and marine applications. Lastly, a 9 oz/yd² fiberglass fabric is considered to be on the heavier side for lightweight applications, but still falls within the lightweight category. This weight provides a greater level of strength and durability, making it suitable for applications such as industrial equipment, tanks, and heavy-duty structures. It is important to note that these weight categories are just general guidelines, and the specific requirements of each application may vary. Consulting with a fiberglass fabric supplier or manufacturer can provide more specific recommendations based on the intended use and desired performance of the lightweight application.

- Q: Are there any specific fire-resistant properties associated with fiberglass fabrics?

- Yes, fiberglass fabrics have specific fire-resistant properties. Fiberglass is inherently fire-resistant because it is made from a combination of glass fibers and resin. The glass fibers in fiberglass fabrics do not burn, melt, or emit toxic gases when exposed to flames or high heat. This makes fiberglass fabrics highly resistant to ignition and combustion. Additionally, fiberglass fabrics have a high ignition temperature, which means that they require a higher temperature to catch fire compared to other materials. Moreover, fiberglass fabrics have low heat conductivity, meaning that they do not transfer heat easily, further enhancing their fire-resistant properties. Due to these characteristics, fiberglass fabrics are commonly used in various applications that require fire safety, such as protective clothing, curtains, insulation materials, and in the construction of fire-resistant structures.

- Q: How is fiberglass fabric used in the production of insulation ropes?

- Due to its exceptional thermal insulation properties and durability, fiberglass fabric is widely utilized in the manufacturing of insulation ropes. The fabric undergoes initial weaving or knitting using thin strands of fiberglass, resulting in a resilient and flexible structure. During the manufacturing process, it is customary to apply a heat-resistant silicone or acrylic coating to the fiberglass fabric. This coating serves to enhance its resistance to high temperatures and bolster its capacity to withstand wear and tear. Additionally, it functions as a preventive measure against the fabric becoming undone or frayed. To create the insulation ropes, the coated fiberglass fabric is skillfully braided or twisted, yielding a tightly woven rope-like formation. This construction technique allows the rope to effectively trap air and establish a thermal barrier, effectively impeding heat transfer and minimizing energy loss. The fiberglass fabric employed in insulation ropes exhibits remarkable resistance to fire, chemicals, and moisture, rendering it suitable for a range of industrial applications. It finds frequent use in HVAC systems, boilers, ovens, and other high-temperature environments where insulation is of utmost importance. In summary, fiberglass fabric assumes a critical role in the production of insulation ropes, offering outstanding thermal insulation, durability, and resistance to various environmental factors. These qualities make it an ideal material for insulating applications.

- Q: What's the price of fiberglass fabric penetrant?

- The company's main fluorocarbon series surfactant, various types of oilfield additives, fire additives, paint additives, rubber additives, fungicides and so on.

- Q: Can fiberglass fabric be used for seals?

- Yes, fiberglass fabric can be used for seals.

- Q: Can fiberglass fabric be used for reinforcement in septic tanks?

- Yes, fiberglass fabric can be used for reinforcement in septic tanks. Fiberglass fabric is known for its strength and durability, making it an excellent choice for reinforcing structures, including septic tanks. The fabric can be used to reinforce the walls and base of the tank, providing additional strength and preventing cracks or leaks. Additionally, fiberglass fabric is resistant to corrosion, which is important in a septic tank environment where there can be high levels of sewage and chemicals. Overall, using fiberglass fabric for reinforcement in septic tanks can enhance their longevity and structural integrity.

- Q: How does fiberglass fabric perform in durability?

- Renowned for its outstanding durability, fiberglass fabric is highly regarded. It boasts exceptional strength and resistance to wear and tear due to its composition of woven glass fibers. Its shape remains intact over time as it is not easily deformed or stretched. Moreover, fiberglass fabric displays remarkable resistance to chemical and environmental factors, including moisture, UV radiation, and extreme temperatures. These qualities render it suitable for diverse applications in industries such as automotive, aerospace, marine, and construction. Furthermore, fiberglass fabric's durability is further amplified by its low maintenance needs and long lifespan, making it a cost-effective and dependable option for a multitude of projects.

- Q: How does fiberglass fabric perform in terms of flexibility?

- Exceptional flexibility is a characteristic for which fiberglass fabric is well known. Its composition of fine glass fibers allows for easy molding and bending into various shapes and contours, all while maintaining its structural integrity. This quality of flexibility makes fiberglass fabric highly versatile, making it suitable for a wide range of applications. Industries such as automotive, aerospace, construction, and even fashion benefit from its adaptability. Moreover, fiberglass fabric's durability is demonstrated by its ability to withstand repeated bending and stretching without significant wear and tear. This durability makes it an ideal choice for projects that require long-term flexibility. In conclusion, fiberglass fabric offers designers and manufacturers the freedom to create innovative and dynamic products, thanks to its exceptional performance in terms of flexibility.

- Q: Is fiberglass fabric resistant to rot and decay?

- Yes, fiberglass fabric is resistant to rot and decay.

Send your message to us

Woven Fiberglass Fabric Continuous Stand Mat 2024 - China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords