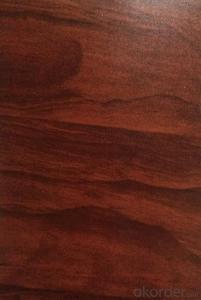

Copper Aluminum Coil Wooden Grain Coating Aluminum Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wooden grain coating aluminum sheet

Specifications

1. no color difference

2.anticorrosion

3.high wearability

4.good formability

Alloy | AA1100/AA1050/1050A/AA1060/AA1070/AA3003/AA3104/AA3105/ AA5052/AA5005/AA5083/AA6061/AA7075/AA8011 |

Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,etc |

Arts | DC or CC |

Coating finish | PVDF & PE |

Paint brands | PPG,SHELL, WHISPER,LILY,ETC. |

Thickness of paint | 5micron-25micron |

Application | ACP,aluminum honeycomb plate,ceiling,roof,aluminum curtain wall,roller shutter door,garages door,furniture,clectronic industry and etc. |

Color | According to RAL color code or the samples provided. |

Certificate | meet GB/ASTM/EN standards, pass ISO9001:2008 quality management system certification and SGS certification. |

Payment terms | 30% T/T in advance as deposit,70% balance against the B/L copy or 100% irrevocable L/C at sight |

Remark | details can be discussed further. |

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a high-quality aluminum coil, consider the following factors: purity level, which should be 99.5% or higher for most applications; surface finish, ensuring it's smooth and free from defects; thickness consistency, which should be uniform across the entire coil; mechanical properties, such as tensile strength and elongation, that meet industry standards; and adherence to specific alloy grades for particular applications. Additionally, check for certifications from recognized standards organizations and consider the supplier's reputation for quality and consistency.</p>

- Q: What are the different grades of aluminum used in coil production?

- There are several different grades of aluminum that are commonly used in coil production. Each grade has its own unique properties and characteristics that make it suitable for specific applications. Some of the most commonly used grades include: 1. 1100 Aluminum: This grade is considered commercially pure aluminum and is known for its excellent corrosion resistance and high thermal conductivity. It is often used in applications such as heat exchangers, fin stock, and evaporator coils. 2. 3003 Aluminum: This grade is alloyed with manganese, making it stronger and more durable than 1100 aluminum. It also has good formability and weldability properties, making it suitable for a wide range of coil production applications, including roofing, gutters, and general sheet metal work. 3. 5052 Aluminum: This grade is alloyed with magnesium and has excellent corrosion resistance and high strength. It is commonly used in marine applications, such as boat hulls and components, as well as in architectural and automotive applications. 4. 6061 Aluminum: This grade is one of the most versatile aluminum alloys and is known for its high strength and excellent machinability. It is often used in structural applications, such as aircraft parts, truck frames, and industrial equipment. 5. 7075 Aluminum: This grade is one of the highest strength aluminum alloys available and is commonly used in aerospace and defense applications. It has excellent fatigue resistance and is often used in the production of aircraft wing spars, fuselage frames, and missile components. These are just a few examples of the different grades of aluminum used in coil production. The specific grade chosen will depend on the desired properties and requirements of the application.

- Q: Are aluminum coils compatible with other materials?

- Yes, aluminum coils are compatible with other materials. Aluminum is a versatile and widely used material that can be easily integrated with various other materials in different applications. For example, aluminum coils can be used in conjunction with copper tubing in air conditioning and refrigeration systems to enhance heat transfer efficiency. Additionally, aluminum coils can be coated or laminated with other materials such as polymers or paints to provide additional protection against corrosion, improve aesthetics, or enhance specific performance characteristics. Therefore, aluminum coils offer compatibility with a range of materials, making them suitable for diverse applications in industries such as construction, automotive, aerospace, and more.

- Q: How do aluminum coils contribute to energy efficiency?

- Aluminum coils contribute to energy efficiency by improving the heat transfer efficiency in various applications. The high thermal conductivity of aluminum allows for better heat exchange, resulting in reduced energy consumption and increased overall efficiency of cooling and heating systems. Additionally, aluminum coils are lightweight and durable, making them more efficient to manufacture, transport, and install, thus reducing energy requirements throughout their lifecycle.

- Q: I have a electrical project to do, and could save about $300.00 by using aluminum wire since I can get it free, but I have never used aluminum before, and am not sure if it is a good way to go.

- I would not recommend it. Aluminum wire expands and contracts a great deal causing the connections to become loose, or break. That is what I was taught.

- Q: Its currently 3 AM so i can't check, but my question is:does aluminum rust slower/faster than other metals? I've basically had this bike for about 6 years, but only rid it once. Its been sitting in my backyard under a roof (safe from rain) for 6+ years. Is it safe to ride it? Also, bonus question: Does having a bike on campus make life 10x easier?

- There is something even worse than keeping a bike under a tarp and ignoring it for 6 years... that is to put the bike in a shed with pool chemicals EVEN IF the chemicals are closed. The presence of the chemicals will rot the bike away to an unusable pile of crap in a matter of months. You will have to take your bike to a shop to have it checked out. Depending on what college you are attending there may be a requirement that it be inspected and licensed.

- Q: Aluminum silicate felt fiber needle blanket noise reduction?

- Aluminum silicate needled blanket belongs to the porous material, porosity higher than ninety-six percent in noise reduction has an absolute advantage, because the aluminum silicate needled blanket belongs to soft products, the lack of stress in the industrial application, so there is no large-scale promotion, mainly used in the silencing device of heavy trucks, trucks and cars. And in the heat insulation, aluminum silicate needled blanket technology with a special one-time plastic molding, as the car chassis fireproof heat insulation layer, and now Xiamen Kinglong has reached a cooperation agreement.

- Q: What is the weight of an aluminum coil?

- The weight of an aluminum coil can vary depending on its size, thickness, and length. On average, aluminum coils typically weigh between 1,500 and 6,000 pounds. However, it is essential to note that specific aluminum coils can weigh more or less depending on the specific requirements and specifications of the coil.

- Q: How can you tell the difference between aluminum and other non-magnetic metals, such as what I've heard called, pot-metal?

- Aluminum is very light. Pot metal, also known as white metal, die-cast zinc, or monkey metal,[1] is a slang term that refers to alloys that consist of inexpensive, low-melting point metals used to make fast, inexpensive castings. There is no scientific metallurgical standard for pot metal; common metals in pot metal include zinc, lead, copper, tin, magnesium, aluminium, iron, and cadmium. The primary advantage of pot metal is that it is quick and easy to cast. Due to its low melting temperature no sophisticated foundry equipment is needed and specialized molds are not necessary. It is sometimes used to experiment with molds and ideas before using metals of higher quality. Examples of items created from pot metal include toys, furniture fittings, tool parts, electronics components, and automotive parts.[citation needed] Pot metal can be prone to instability over time, as it has a tendency to bend, distort, crack, shatter, and pit with age.[1] The low boiling point of zinc and the fast cooling of the newly-cast part often allow air bubbles to remain within the cast part, weakening the metal.[1] Many of the components of pot metal are susceptible to corrosion from airborne acids and other contaminants, and the internal corrosion of the metal often causes the decorative plating to flake off.[citation needed] Pot metal is not easily glued, soldered or welded.[1] At one time, pot metal referred to a copper alloy that was primarily alloyed with lead. 67% Cu, 29% Pb 4% Sb and 80% Cu, 20% Pb were common formulations.[2] The primary component of pot metal is zinc, but often the caster adds other metals to the mix to strengthen the cast part, improve the flow of the molten metal, or to reduce cost.[dubious – discuss] With a low melting point of 419 °C (786 °F), zinc is often alloyed with other metals including lead, tin, aluminium and copper.

- Q: Is it possible to use a welding torch for joining steel coils?

- <p>Yes, you can use a welding torch to weld steel coils together. However, it's important to choose the right type of welding process suitable for the specific steel grade and the desired strength of the joint. Common methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). Ensure you follow safety protocols, use appropriate protective gear, and have a good understanding of the welding process to achieve strong, reliable welds.</p>

Send your message to us

Copper Aluminum Coil Wooden Grain Coating Aluminum Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords