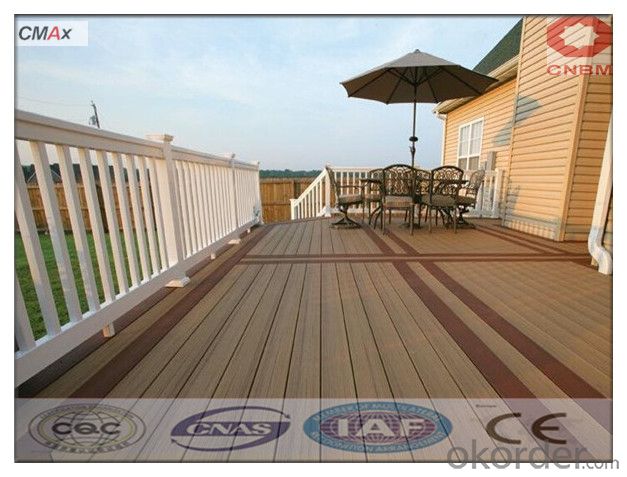

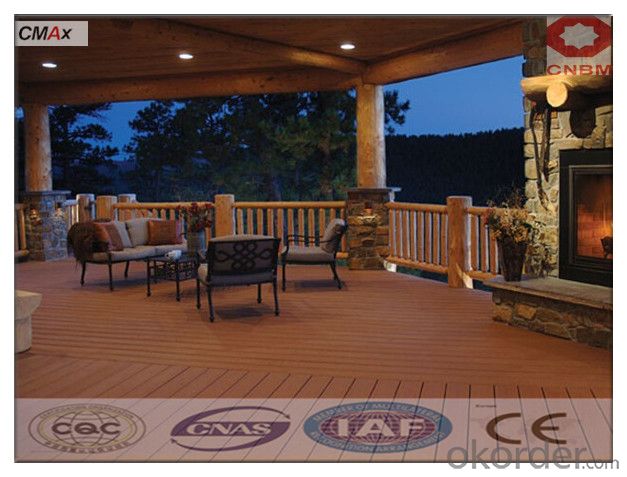

Wood Plastic Composite WPC Tiles Wood Composite Floor Decoration Outdoor

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

Product name | WPC decking series |

Size | 40x10mm 40x15mm 55x15mm 60x50mm 65x15mm 90x15mm 90x20mm 90x30mm 100x25mm 100x50mm 120x120mm 130x23mm 140x25mm 140x35mm 140x40mm 142x25mm 145x30mm 148x10mm 150x20mm 150X25mm |

Design | Hollow decking |

Length | From your required |

Surface treatment | Original, sanded, brushed |

Color available | regular colors for choice (light brown, dark grey, dark brown, light grey, green yellow) and we can adjust the new color according to the order requirement |

Characteristics | 1. Looks and feels like natural wood 2. Durable, firm because of its high density 3. High degree of UV and color stability, 4. Easy to install and low labor cost 5. Requires no painting, no glue, low maintenance 6. 100% recycle, environmental friendly, saving forest resources 7. Barefoot friendly, anti-slip, no cracking |

Application | 1.Landscape works: outdoor decking, garden pavilion, fences, handrails, doors, windows, home decor |

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Home improvement with a good floor or a good tiles

- Personally think that with the composite floor is relatively easy to scrub

- Q: We are putting in maple floors and are considering engineered wood. Trying to research the engineered floors, I see alot of positives and not the negatives - yet there must be some! Any opinions?Also - would one be easier to install than the other?If it matters ... This is for the 1st floor our our house in South Eastern MA (about 6 miles from the ocean). Thanks

- If money is no object, get the real thing; it will not look as perfect and it will age faster.

- Q: Is it good for solid wood flooring? Tangled. The

- Is it good for solid wood flooring? Tangled. The

- Q: We're putting in an engineered floor in our kitchen and are trying to decide whether to staple or glue it down. There doesn't seem to be a preference from the manufacturer's information, just instructions on how to do either one.

- If you glue it, nothing will show, like staples.

- Q: Is the laminate flooring orange and can you paint on the green above? / More

- Do not need to paint the paint, if you have to brush, you will find health is more difficult to do, strengthen the surface of the composite floor is aluminum oxide, the paint is easy to fall off, especially after the paint is more ugly The Moreover, the processing of the factory is better than the artificial nature, artificially remove the previous paint and brush on the new, not only not easy to ensure stability, and will bring room for the immeasurable pollution, that is, the use of so-called good paint is also possible The Paint contained in toluene and xylene, the health of their families.

- Q: My family is preparing to decorate, is considering the floor or floor tiles, we intend to live with the room with the room is also a rough dwarfed gnome dumplings evil spear pave the floor, but a friend said my house east-west, sunny, afraid of the floor can not stand Alice Is it really like this? There is a large living room area, the floor is assembled. Easy to loose more

- Can, when you buy the floor can be directly called the workers of the factory workers to shop the floor, they are very lazy rough Zen dumplings stubborn spear professional shop very good, composite floor sun is not arching, unless it is inside the floor have water.

- Q: Want to wax? How to play better

- No need, only solid wood flooring needs waxing

- Q: Sales master laminate flooring master said that do not have to do to promote the production of the floor, the floor of the master said, "Strengthen the composite floor to do curing to maintain its long." No search for the answer. Please have experienced master answer. Question added: Will the use of conservation to strengthen the composite floor. More

- The floor is a layer of aluminum oxide, and there is no need for special maintenance. Of course, if the surface to play wax, can maintain a good brightness. In the usual use of the process should pay attention to protection, to prevent moisture, to prevent hard scratches, etc. on it.

- Q: And the floor of the floor is low, you have to raise the door frame, tile workers do not want to lift the door when the workers, leveling down the door when the pressure down one centimeter of cement, so that the door Can you lay the floor?

- Absolutely can not! The According to the provisions of the ground floor pavement composite floor, the level requirements are as follows: with the level of the card, within 1 meter shall not have more than 3MM this standard you can query the "floor pavement acceptance specifications" The general pavement we will be slightly wider than the national standard, will not exceed 5MMM, but to a centimeter, is absolutely impossible, especially the door, the larger flow of people on the floor damage.

Send your message to us

Wood Plastic Composite WPC Tiles Wood Composite Floor Decoration Outdoor

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords