Wire rod with hot price 5.5mm-12mm different grade

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 19710 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Produced from billets at the rolling mill, wire rod is the basis of all steel wire, rope and fencing products.

The most important characteristic in determining wire rod’s end use is its drawability. Common low carbon

wire rod is used for nails, small shaped products, barbed wires, various wire nettings, steel chains, and other

applications. High Carbon wire rod uses include steel tire cords for automobiles, conveyor belts, and pressure

hoses. Other applications include bolts, nuts, and machine parts, as well as compression, tension and torsion

springs

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

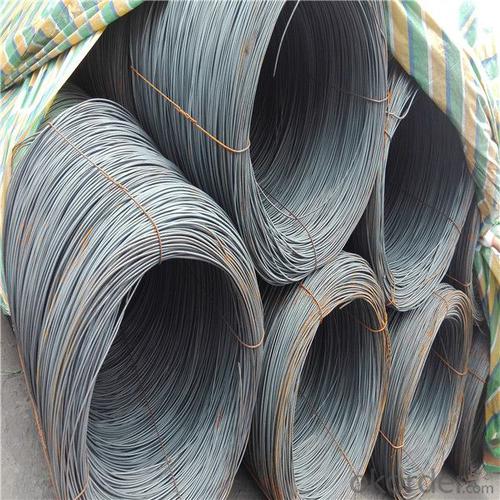

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is steel wire rod used in the manufacturing of wire forms for ski lifts?

- Steel wire rod is an essential component in the manufacturing of wire forms for ski lifts. These wire forms are responsible for providing the necessary support and strength to the ski lift system. Firstly, steel wire rod is used to create the primary cables that run along the ski lift structure. These cables bear the weight of the ski lift and its passengers, ensuring their safety and stability. The high tensile strength of steel wire rod is crucial in withstanding the heavy loads and stress that the ski lift system experiences during operation. Additionally, steel wire rod is utilized in the creation of the suspension cables that connect the ski lift cabins to the primary cables. These suspension cables play a vital role in keeping the cabins balanced and levelled while in motion. The durability and reliability of steel wire rod ensure that these suspension cables can withstand the constant movement and varying forces exerted on them. Moreover, steel wire rod is also used in the construction of safety cables that are installed as a precautionary measure. These safety cables act as a backup system, providing an additional level of security for the ski lift passengers. In case of any unforeseen event or malfunction, the safety cables ensure that the cabins remain securely attached to the primary cables, preventing any potential accidents. Overall, steel wire rod serves as the backbone of wire forms for ski lifts by providing the necessary strength, stability, and safety required for their operation. The quality and durability of steel wire rod play a crucial role in ensuring the reliability and longevity of ski lift systems, ultimately contributing to the safety and enjoyment of skiers and snowboarders.

- Q: What are the main components of a steel wire rod mill?

- The main components of a steel wire rod mill include a reheating furnace, roughing mill, intermediate mill, finishing mill, cooling bed, and coiling machines. The reheating furnace is used to heat the raw material, which is typically billets or ingots, to a temperature suitable for rolling. This helps in reducing the material's brittleness and improving its plasticity. The roughing mill is responsible for reducing the thickness of the heated material through a series of rolling passes. It consists of multiple stands of rolls that gradually decrease the size of the material. After the roughing mill, the material is passed through the intermediate mill. This mill further reduces the thickness and improves the surface quality of the wire rod. The finishing mill is the final stage of the rolling process. It consists of several stands of rolls that give the wire rod its final dimensions and surface finish. This mill is crucial in achieving the desired mechanical properties and dimensional accuracy of the wire rod. Once the wire rod is rolled to the desired shape and size, it is then transferred to the cooling bed. The cooling bed allows the wire rod to cool down gradually, preventing any deformation or cracking due to the high temperatures from the rolling process. Finally, the coiling machines are used to coil the wire rod into spools or coils, making it easier for transportation and storage. Overall, these main components work together in a steel wire rod mill to transform raw materials into high-quality wire rods that can be used in various industries such as construction, automotive, and manufacturing.

- Q: What are the different surface protection materials used for steel wire rod?

- Steel wire rods can be protected using various surface protection materials. These materials are applied to the wire rod's surface to prevent corrosion and other forms of damage. One commonly used surface protection material for steel wire rods is zinc coating. This involves immersing the wire rod in a hot-dip galvanizing process, which results in a layer of zinc on its surface. Zinc acts as a highly effective corrosion inhibitor and creates a protective barrier between the steel and its environment. This coating is typically used for wire rods that will be exposed to harsh or corrosive conditions. Polymer coating is another surface protection material for steel wire rods. It can be applied using different methods like extrusion or dip coating. These coatings serve as a barrier against moisture, chemicals, and abrasion, effectively preventing corrosion and prolonging the wire rod's lifespan. Polymer coatings are commonly used for wire rods in indoor or outdoor applications that require corrosion resistance. Phosphate coating is a surface protection material that involves immersing the wire rod in a phosphate solution, resulting in a thin phosphate layer on its surface. This coating enhances adhesion for subsequent coatings or paints and offers some corrosion resistance. It is often used as a pre-treatment before applying other surface protection materials. Lastly, epoxy coating is a widely used surface protection material for steel wire rods. It is typically applied through electrostatic spray deposition. Epoxy coatings provide excellent corrosion resistance, chemical resistance, and durability. They are commonly used for wire rods exposed to harsh environments like marine or industrial applications. In conclusion, various surface protection materials, including zinc coating, polymer coating, phosphate coating, and epoxy coating, can be applied to steel wire rods. The selection of these materials depends on the specific requirements of the wire rod and its intended application.

- Q: How is steel wire rod used in the production of tire reinforcement materials for heavy-duty vehicles?

- Steel wire rod is used in the production of tire reinforcement materials for heavy-duty vehicles as it provides strength and durability. The wire rod is typically formed into cords or strands and then embedded within the rubber compound of the tire. This reinforcement helps to enhance the tire's structural integrity, improve its load-carrying capacity, and increase its resistance to wear and tear. Overall, steel wire rod plays a vital role in ensuring the performance and longevity of tires used in heavy-duty vehicles.

- Q: What are the different rolling processes used for steel wire rod production?

- Steel wire rod production utilizes various rolling processes, each with its own merits and uses. 1. The most prevalent and widely employed method is hot rolling. This entails heating steel billets to high temperatures and passing them through rolling mills. Hot rolling yields a more malleable and flexible wire rod, making it suitable for applications in construction, automotive, and manufacturing industries. 2. In contrast, cold rolling involves rolling the wire rod at room temperature. This process enhances the wire rod's surface finish and dimensional accuracy. Additionally, it improves the mechanical properties, enabling its use in specialized applications such as high-strength wires, springs, and electrical conductors. 3. Continuous casting and rolling combine the casting and rolling processes into a seamless operation. Molten steel is directly cast into thin slabs or billets, which are then rolled into wire rods without intermediate reheating. This integration offers advantages like enhanced efficiency, reduced energy consumption, and improved product quality. 4. Microalloying rolling incorporates small amounts of alloying elements into the steel composition to enhance its strength and other mechanical properties. This method is commonly employed in the production of high-strength wire rods for construction, infrastructure, and automotive industries. 5. Thermomechanical rolling employs a combination of hot rolling and controlled cooling to achieve specific mechanical properties. By manipulating the cooling rate, the microstructure of the wire rod can be altered, resulting in improved strength, toughness, and formability. This process is often utilized in the production of high-quality wire rods for critical applications such as suspension cables, ropes, and steel reinforcement. In conclusion, the choice of rolling process for steel wire rod production depends on factors such as desired mechanical properties, surface finish, and application requirements. Each process provides distinct advantages, enabling manufacturers to tailor wire rods to specific applications.

- Q: How is steel wire rod used in the manufacturing of wire for agricultural fencing?

- Steel wire rod is used in the manufacturing of wire for agricultural fencing by being drawn through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, results in a strong and durable wire that is then woven or welded into the desired fencing shape. The high tensile strength of steel wire rod ensures that the agricultural fencing can withstand the pressure and stress it may encounter in outdoor environments, making it an ideal material for securing livestock and crops.

- Q: How does the magnetic properties of steel wire rod vary with different heat treatment processes?

- The magnetic properties of steel wire rod can vary significantly with different heat treatment processes. Heat treatment processes such as annealing, quenching, and tempering can influence the microstructure and crystallographic orientation of the steel, which in turn affects its magnetic properties. For example, annealing can result in the formation of a soft magnetic structure with improved magnetic permeability, while quenching and tempering can produce a harder magnetic structure with higher coercivity. Overall, the specific heat treatment process employed can determine the magnetic properties of steel wire rod, making it possible to tailor its magnetic characteristics for specific applications.

- Q: What are the dimensions and sizes of steel wire rod?

- The dimensions and sizes of steel wire rods can vary depending on the specific requirements and applications. Generally, steel wire rods are available in diameters ranging from 5.5mm to 20mm, with some variations beyond this range. The length of steel wire rods can vary as well, usually ranging from 1.5m to 2m or longer. However, it is important to note that these dimensions and sizes can vary based on the specific industry standards and customer needs.

- Q: How are steel wire rods used in the manufacturing of mesh screens for filtration?

- Due to their strength, durability, and versatility, steel wire rods are vital components in the production of mesh screens used for filtration. To obtain the desired diameter and strength, these rods undergo a series of steps including heating, rolling, and cooling. Once formed, the wire rods are woven or welded together to construct the mesh screen. Mesh screens made from steel wire rods find applications in various industries for filtration purposes. In the water treatment sector, for instance, they are utilized to eliminate impurities, contaminants, and solid particles from water sources. The steel wire rods provide the necessary tensile strength and corrosion resistance, ensuring the longevity and effectiveness of the mesh screen. Customization options are available for the size and spacing of the wire rods used in manufacturing mesh screens for filtration. Different mesh sizes allow for the filtration of various particle sizes, enabling the screens to effectively capture and separate solids from liquids or gases. The steel wire rods also provide stability and structural integrity to the mesh screens, enabling them to withstand high-pressure filtration processes. To enhance their filtration capabilities, steel wire rods can be coated with different materials. For instance, a polymer coating can be applied to prevent clogging and improve the efficiency of the screen. Additionally, the mesh screens can be further processed and shaped into different forms, such as cylinders, cones, or flat sheets, depending on the design and application requirements of the filtration system. In conclusion, steel wire rods are essential in the manufacturing of mesh screens for filtration. Their strength, durability, and adaptability make them an ideal material for creating mesh screens that effectively separate and filter contaminants from various substances. This ensures the quality and purity of liquids and gases in numerous industries.

- Q: How is steel wire rod tested for non-destructive defects?

- Steel wire rod is tested for non-destructive defects using various methods such as ultrasonic testing, magnetic particle inspection, eddy current testing, and visual inspection. These techniques allow for the detection of surface cracks, internal voids, and other imperfections without causing any damage to the wire rod.

Send your message to us

Wire rod with hot price 5.5mm-12mm different grade

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 19710 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords