Widely Used Color Coated Steel Coil/Al-Zn Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Application:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

2.Features:

With excellent cold-rolling steel strips as base material, it has the advantages of

.Good manufacturing performance

.High impact resistance

.Uniform plating thickness

.High adhesive force

.No peeling after forming

.High corrosion resistance

3.Details:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

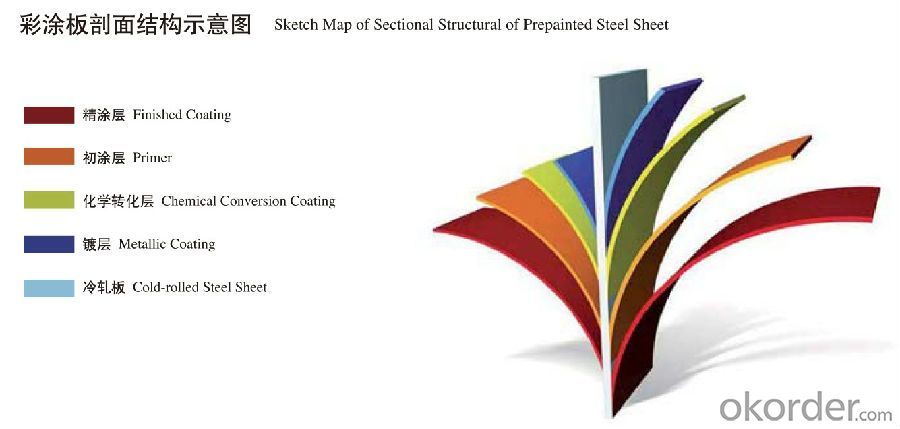

4. Images of steel coils:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Ok I know this sounds stupid but is there anyway to make stainless steel look older? It looks too new and I don't want it like that. Thanks.

- Just abuse it. You could hit with a hammer, expose it to flame, throw it at or grind it around on rocks or concrete, rub it with steel wool. (be artful in how you do this, the pattern could end up looking too deliberate if you're not careful.) For an example of naturally aged stainless steel, look at some cooking pots/pans. If you don't have any old ones, maybe your parents or someone you know does. They usually get a little banged up/scuffed/stained after a while. (I think the stainless just means it doesn't rust.)

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they serve as the primary raw material. These coils are unrolled and then undergo a series of processes such as cutting, shaping, bending, and welding to form the desired shape of the hook. The strength and durability of steel coils make them an ideal material for manufacturing steel hooks, ensuring they can withstand heavy loads and provide reliable support in various applications.

- Q: .Yea, so I just saw the old Conan movie with Arnold. Good movie, but I still don't get it. What IS the riddle of steel???I get that like from the begining Conan's dad is like telling him a story about Crom and giants, and people got steel once Crom killef the giants. Then, later on in the movie Conan's talking to his lil' asian homie, and Conan tells him that when he dies... he'll go before Crom, and Crom will ask him what the riddle of steel is, and if he doesn't know it he'll get kicked out of barbarian heaven!But, what is the riddle of steel???C'mon guys... I want to in to barbarian heaven! LolBut, seriously though... what us it???.

- This Site Might Help You. RE: Movies- Conan: What is the riddle of steel? . Yea, so I just saw the old Conan movie with Arnold. Good movie, but I still don't get it. What IS the riddle of steel?? I get that like from the begining Conan's dad is like telling him a story about Crom and giants, and people got steel once Crom killef the giants. Then, later on...

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork to form the main structure of the ducts. The steel coils are processed and shaped into specific sizes and dimensions, allowing them to be easily fabricated into duct sections. These coils provide strength and durability to the ductwork, ensuring it can withstand the high pressures and temperatures involved in HVAC systems.

- Q: What are the common methods of joining steel coils?

- There are several common methods used for joining steel coils, depending on the specific application and desired outcome. 1. Butt welding: This is a commonly used method where the two ends of the steel coils are aligned and welded together. Butt welding can be done using various techniques such as gas welding, electric resistance welding, or laser welding. This results in a strong and continuous joint without any additional material. 2. Overlapping and stitching: In this method, one end of the steel coil is overlapped onto the other end, and then stitched together using mechanical fasteners like staples, nails, or screws. This technique is suitable for temporary or low-stress applications where disassembly may be required. 3. Mechanical coupling: Steel coils can also be joined using mechanical couplings. These couplings are typically designed to fit over the ends of the coils and securely hold them together. Mechanical couplings are commonly used in pipelines, where the joint needs to be leak-proof and withstand high pressure. 4. Adhesive bonding: Another method of joining steel coils is through the use of adhesives. This involves applying a suitable adhesive or bonding agent to the ends of the coils and then pressing them together. Adhesive bonding allows for a clean and aesthetically pleasing joint, but its strength may vary depending on the adhesive used. 5. Overlapping and welding: Similar to overlapping and stitching, this method involves overlapping the ends of the steel coils and then welding them together. However, instead of using mechanical fasteners, welding is used to create a stronger and more permanent joint. This method is commonly used in structural applications where high strength and durability are required. It is important to note that the choice of joining method depends on factors such as the type of steel, the application requirements, and the desired strength of the joint. Proper consideration should be given to ensure the selected method is suitable for the specific project.

- Q: I'm wondering if steel casings are bad for a 1911. I know that an AK-47 will eat up steel casings all day long, but steel casings are bad for, and can be hard on an AR-15. I only have brass for my AR and that will never change. I'm curious as to how a 1911 fairs with steel casings. Is it bad for the gun or does it not matter? I'm asking because steel cased rounds seem to be the only readily available ammo these days. Thanks

- steel casings go back to the early 1900's for 1911's. Most guns were always able to handle them and most of that has carried on. I would think glocks are a no no for steel for longevity but in the caribbean we have mainly steel casings and that's all we use. the 1911 is probably the most popular hand gun down there. I own one, and FM. Over 1000 rounds so far in her between me and my dad (previous owner)

- Q: What are the different types of steel coil slitting machines?

- There are several types of steel coil slitting machines, including rotary slitters, loop slitters, and stationary slitters. Rotary slitters use rotating circular blades to cut the coils into desired widths, loop slitters use a looping process to cut the coils, and stationary slitters use stationary blades to slit the coils. Each type of machine has its own advantages and is suitable for different applications.

- Q: Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- Nylon Guitar Strings Vs Steel

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- CS is a noxious gas that I have tasted. If it is spec mild steel then do so.

Send your message to us

Widely Used Color Coated Steel Coil/Al-Zn Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords