Wide Aluminum Coil for Radiator - Grade Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Coil Grade for Radiator Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminum Coil Grade for Radiator :

1) Radiator

2) Condenser

3) Insulation Material

4) construction

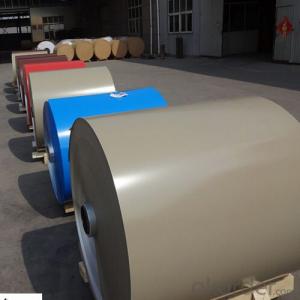

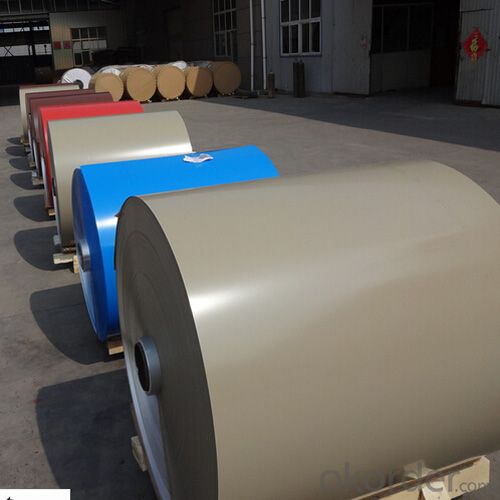

3. Aluminum Coil Grade for Radiator Images:

4. Aluminum Coil Grade for Radiator Specification:

Products | Alloy | Temper | Thickness(mm) | Width(mm) | length |

| Aluminum coil | 1XXX, 3003 8011, 3105 | H14, H16, H18, H24 , O | 0.08mm-6.0mm | 200mm-1500mm | 500mm-4000mm |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: I want to paint my cars rims and grill metallic pink. But supposedly paint doesn't stick well to aluminum. What can I do to make it stick better and not chip?

- make sure the aluminum is ruffed up with at least 800 grit sand paper after that clean well and make sure is is dry after you clean after that use a product called adhesion promoter it will help the paint stick to the wheel hope this helps

- Q: What are the standard dimensions for aluminum coils?

- The dimensions of aluminum coils can vary depending on their intended use and the industry they are being used in. However, there are generally accepted standard dimensions for aluminum coils. In terms of width, aluminum coils can range from 4 inches (10 cm) to 60 inches (152 cm). The exact width will depend on factors such as the purpose of the coils, the manufacturing process, and the customer's specifications. When it comes to thickness, aluminum coils are available in various gauges or millimeters. Common thicknesses can range from 0.018 inches (0.46 mm) to 0.25 inches (6.35 mm) or even thicker in certain applications. The length of aluminum coils can also vary based on customer requirements or industry standards. Coils can be supplied in standard lengths, such as 1000 feet (304.8 meters) or 2000 feet (609.6 meters), or they can be custom-cut to a specific length. It is important to note that these dimensions are not fixed and can be customized to suit the needs of a particular project. Different industries, like construction, automotive, and aerospace, may have their own specific size requirements for aluminum coils. Therefore, it is recommended to consult with an aluminum coil manufacturer or supplier to determine the most appropriate dimensions for a specific application or project.

- Q: The user is asking if it's possible to create furniture using aluminum coils.

- <p>Yes, you can use aluminum coils to make your own furniture. Aluminum is a versatile material known for its strength, durability, and lightweight properties, making it suitable for furniture construction. You can bend and shape aluminum coils to create unique designs for chairs, tables, or shelving. However, it's essential to have the right tools and skills for cutting, bending, and joining the coils. Ensure you follow safety precautions when working with metal, and consider the structural integrity and weight distribution of your design to ensure the furniture's stability and longevity.</p>

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils can vary depending on the specific manufacturing process and industry standards, but it is typically within a range of +/- 0.005 to 0.010 inches.

- Q: Is it possible to customize the dimensions of aluminum coils?

- Yes, it is possible to customize the dimensions of aluminum coils. Aluminum coils can be cut and shaped according to specific requirements and dimensions based on the application they are intended for. Customization allows for flexibility in design and ensures the aluminum coils meet the specific needs of the project.

- Q: Can aluminum coils be bent or shaped?

- Yes, aluminum coils can be bent or shaped with the appropriate tools and techniques.

- Q: What precautions should be taken when handling aluminum coils to ensure safety?

- <p>When using aluminum coils, safety measures include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure the work area is well-ventilated to avoid inhaling fumes from any processes involving the coils. Keep the coils dry to prevent electrical hazards. Use proper handling equipment to avoid back injuries from heavy loads. Always follow the manufacturer's guidelines for the specific aluminum coil products being used. Regularly inspect the coils for any signs of damage or wear that could lead to accidents.</p>

- Q: Is it possible to utilize aluminum coil as a conductor for speaker wires?

- <p>While it is technically possible to use aluminum coil as speaker wire, it is not recommended. Aluminum has higher resistance and lower conductivity compared to copper, which is the standard material for speaker wires. This can result in signal loss and reduced sound quality. Copper is preferred due to its superior electrical conductivity, ensuring minimal signal degradation over distance. For optimal audio performance, it's best to use speaker wire made from high-quality copper or copper-clad aluminum.</p>

- Q: Explain the differences between aluminum coil and aluminum foil when used in food packaging.

- <p>Aluminum coil and aluminum foil are both used in food packaging but serve different purposes. Aluminum coil is typically thicker and more rigid, used for making aluminum cans and containers. It provides a strong barrier against light, air, and moisture, which is crucial for preserving the quality and freshness of food. Aluminum foil, on the other hand, is thinner and more flexible, often used for wrapping food to protect it from contamination and to retain heat or cold during cooking or storage. It's also used for baking and roasting to prevent food from sticking to the pan or to add a crispy texture. While both materials are recyclable and provide a barrier against external elements, their specific applications in food packaging differ based on their physical properties and the needs of the packaging process.</p>

- Q: Which aluminum roll is good?

- Buy aluminum volumes, choose Shanghai Jin language metal materials Co., Ltd., Shanghai Jin language metal materials Co., Ltd. is committed to aluminum coil wholesale, sale and processing.

Send your message to us

Wide Aluminum Coil for Radiator - Grade Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords