Wholesale Roofing Aluminum Coil - Aluminium Coil with PVDF Coating Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil with PVDF Coating Good Quality:

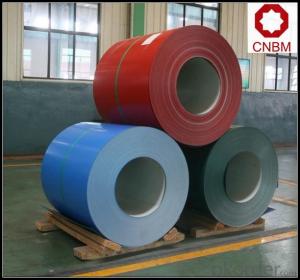

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil with PVDF Coating Good Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

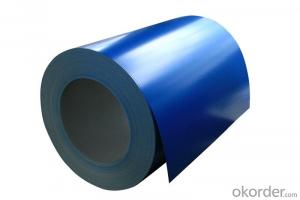

Images of the Aluminium Coil with PVDF Coating Good Quality:

Aluminium Coil with PVDF Coating Good Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil with PVDF Coating Good Quality:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be fabricated or formed into different shapes?

- Yes, aluminum coils can be fabricated or formed into different shapes through various processes such as bending, rolling, stamping, or extrusion. These techniques allow for the creation of customized shapes and designs to fit specific applications or requirements.

- Q: Aluminum coil Kaiping is out of arc plate, what's the matter?

- Aluminum coil Kaiping need to use "stretch bending straightening machine" to do leveling, before they can be leveled

- Q: What are the energy efficiency benefits of aluminum coils?

- Aluminum coils offer several energy efficiency benefits. Firstly, aluminum is a highly conductive material, allowing for faster and more efficient heat transfer compared to other coil materials. This leads to improved cooling or heating performance, reducing energy consumption. Additionally, aluminum coils are lightweight, which means less energy is required to move them, resulting in energy savings during transportation and installation. Moreover, aluminum's corrosion resistance properties ensure the longevity of the coils, reducing the need for frequent replacements and minimizing overall energy consumption. Lastly, aluminum is a recyclable material, contributing to sustainability and reducing the energy-intensive process of manufacturing new coils.

- Q: How are aluminum coils cleaned before further processing?

- Aluminum coils are typically cleaned before further processing through a combination of mechanical and chemical methods. The coils are first mechanically cleaned to remove any loose dirt or debris using brushes or air jets. This step helps to prepare the surface for the subsequent chemical cleaning process. Chemical cleaning involves the use of acids or alkaline solutions that help to remove any remaining contaminants, such as oils, grease, or oxidation layers. The coils are either immersed in the cleaning solution or sprayed with it, which helps to dissolve and remove the impurities. Once the cleaning process is complete, the coils are rinsed with water to remove any residues from the cleaning agents.

- Q: We are working on a new aluminum fixture. It is basically an aluminum spine with many 6061-T6 pins sticking out. Currently we drill the holes inside the spine and hammer the 5/32 6061-T6 pins inside. Is there anyway to cast aluminum with many 6061-T6 pins embedded (they will stick out after the casting)?

- this may be a splash extra complicated yet promises extra advantageous element than sand casting. lost wax casting investment or ceramic shell you'll be able to make molds to form the wax yet investment or ceramic shell are destroyed interior the approach

- Q: Can aluminum coils be used in the production of heat exchangers?

- Yes, aluminum coils can be used in the production of heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for efficient heat transfer and helps in optimizing the overall performance of the heat exchanger.

- Q: What is the typical coil width for aluminum coils?

- The typical coil width for aluminum coils can vary, but it is commonly found in the range of 12 inches to 60 inches.

- Q: if air goes throught a lot of tiny aluminum will cause cooling? Why am i asking this because when you see inside the computer desktop has heatsink fan, and some of the heatsink are made by aluminum.

- Aluminium doesn't 'cause' cooling, but it is efficient at dissipating heat. Copper is too, which is why both metals are often used to make heatsinks.

- Q: This question seeks advice on methods to prevent rust formation on aluminum coils.

- <p>To prevent rust on aluminum coil, ensure proper storage conditions by keeping the coils dry and avoiding contact with moisture. Use protective coatings or sealants that are compatible with aluminum to create a barrier against the elements. Regularly inspect the coils for signs of corrosion and clean them with a non-abrasive cleaner to remove any contaminants. Avoid using harsh chemicals that could accelerate oxidation. Maintain good ventilation in storage areas to reduce humidity, which can contribute to rust formation. Finally, consider using anodizing or other surface treatments that enhance the aluminum's natural resistance to corrosion.</p>

- Q: What are the weight and thickness options for aluminum coils?

- The weight and thickness options for aluminum coils can vary depending on the specific needs and requirements of the project or application. Generally, aluminum coils can range in weight from a few hundred pounds to several thousand pounds, while the thickness can range from a few millimeters to a few inches. It is important to consult with a supplier or manufacturer to determine the appropriate weight and thickness options based on the intended use of the aluminum coils.

Send your message to us

Wholesale Roofing Aluminum Coil - Aluminium Coil with PVDF Coating Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords