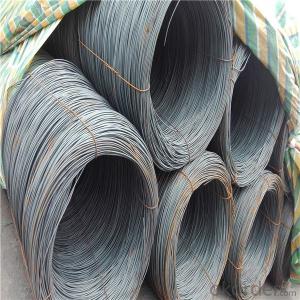

Wholesale 8.5mm steel wire rod in coils from Bao Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Grade: Q195/235, SAE1006-1018B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: HSKY

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:(Please kindly find our chemistry of our material based on SAE1006B and SAE1008B as below for your information)

High carbon/Low carbon/common carbon Steel wire rod | With boron for rebate tax |

Grade | SAE1006B SAE1008B SAE1018B |

Package | In coil ,in bundle, |

Coil weight | about 2000kg-3000kgs |

Size: | 5.5mm 6.5mm 8mm 10mm 12mm 14mm 16mm |

Types | High Carbon ,Low carbon ,Common carbon |

Exported Country | South Korea,Vietnam,Indonesia,Myanmar,Philippines and Afrca,Ect |

Delivery term: | within 30 days after receive the LC |

Payment Term: | LC at sight ,LC 30-120 days after B/L date, TT payment |

The Standard of Physical Properties:

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | Cr | |

SAE1006 | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | >0.30 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

250-280 | 350-380 | ≥32 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | Cr | |

SAE1008 | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.30 min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥30 | ||||

Usage and Applications of Steel Wire Rod in Coil:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on, Since most of the products are round, it is generally called wire rod. Steel wire rod is widely used in construction and manufacturing. Steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts, nail etc) materials, especially used to produce wire drawing, welding electrode, nails,spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Steel Wire Rod in Coil:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

- Q: How is steel wire rod used in the manufacturing of wire for solar panels?

- Steel wire rod is used in the manufacturing of wire for solar panels as it provides strength and durability to the wires. The steel wire rod is first drawn into thin strands and then coated with a protective material to prevent corrosion. These wires are then used in the construction of solar panels to connect the photovoltaic cells and carry the electrical current generated by them.

- Q: What are the different surface defects that can impact the electrical resistance of steel wire rod?

- Some common surface defects that can impact the electrical resistance of steel wire rod include scale, rust, pits, scratches, and uneven surfaces. These defects can create barriers to the flow of electricity, leading to increased resistance and potentially affecting the wire rod's performance in electrical applications.

- Q: How is steel wire rod classified based on its chemical composition?

- Steel wire rod is classified based on its chemical composition into different grades or types. The classification is primarily determined by the levels of carbon and alloying elements present in the steel. Low carbon steel wire rod, also known as mild steel, typically contains a carbon content ranging from 0.05% to 0.25%. This type of steel is often used for general-purpose applications such as construction, automotive, and machinery. Medium carbon steel wire rod contains a higher carbon content, usually between 0.25% and 0.60%. This grade of steel offers increased strength and hardness, making it suitable for applications that require higher tensile strength, such as springs, wires, and cables. High carbon steel wire rod contains a carbon content of over 0.60%. This grade of steel is known for its exceptional strength and hardness. It is commonly used in the manufacturing of high-strength wires, guitar strings, and cutting tools. Alloy steel wire rod is composed of multiple alloying elements such as chromium, nickel, manganese, or molybdenum, in addition to carbon. These alloying elements enhance specific properties of the steel, such as corrosion resistance, heat resistance, or wear resistance. Alloy steel wire rod is often used in specialized applications such as automotive components, fasteners, and machinery parts. In summary, steel wire rod is classified based on its chemical composition, with varying carbon and alloying element levels determining its specific grade or type. This classification helps in selecting the appropriate steel wire rod for specific applications based on the desired mechanical properties and performance requirements.

- Q: How are steel wire rods used in the production of welding electrodes?

- The production of welding electrodes relies heavily on steel wire rods, which serve as vital components. These wire rods function as the central material for welding electrodes, supplying the essential strength and conductivity needed for welding. To initiate the production of welding electrodes, steel wire rods are carefully chosen based on their specific mechanical properties. These properties, such as tensile strength and elongation, guarantee that the welding electrodes can endure the demanding conditions of high temperatures and stress encountered during welding. The steel wire rods then undergo further processing through a series of steps. Initially, they are cleansed and coated with a flux material. This coating aids in the elimination of impurities and facilitates improved arc stability during welding. Moreover, the coating helps create a protective gas shield around the welding area, preventing oxidation and contamination. Once the coating process is complete, the steel wire rods are cut into predetermined lengths and shaped according to the desired electrode design. This may involve bending or forming the rods to achieve the required shape and size for the welding electrode. Once the welding electrode is shaped, it is packaged and prepared for distribution and use. These electrodes find extensive applications in various industries, including construction, automotive, and manufacturing, where they are utilized for welding tasks like metal joining, machinery repair, and structure fabrication. In conclusion, steel wire rods play a critical role in the production of welding electrodes, providing the necessary strength, conductivity, and formability required for these electrodes to effectively carry out welding processes.

- Q: How is steel wire rod used in the production of suspension springs for aircraft?

- Steel wire rod is commonly used in the production of suspension springs for aircraft due to its high strength and durability. The wire rod is first drawn to the desired diameter and then coiled to form the spring. The coiled wire rod is then heat-treated to improve its mechanical properties, such as resilience and fatigue resistance. These suspension springs play a vital role in absorbing shocks and vibrations during flight, ensuring a smooth and stable ride for the aircraft.

- Q: What are the common applications of spring steel wire rod?

- Spring steel wire rods have a wide range of applications due to their unique properties. Some common uses include manufacturing springs, wire forms, clips, fasteners, and mechanical components such as shafts and pins. They are also used in the automotive industry for suspension systems, seat frames, and engine components. Additionally, spring steel wire rods are utilized in the construction industry for reinforcing concrete, as well as in the manufacturing of various tools and equipment.

- Q: How is the fatigue resistance of steel wire rod tested?

- The fatigue resistance of steel wire rod is typically tested using a cyclic loading test called the rotating bending fatigue test. In this test, a specimen of the steel wire rod is subjected to repeated cyclic bending under controlled conditions. The test begins by mounting the specimen onto a rotating device, such as a rotating beam or a rotating wheel. The specimen is then subjected to a cyclic bending load that varies in magnitude and direction. This load is applied by a mechanical or hydraulic device that applies the bending force to the specimen at a constant frequency. During the test, the number of cycles and the applied stress or load are carefully monitored. The test is usually conducted until the specimen fails due to fatigue, which is defined as the occurrence of cracks, fracture, or permanent deformation. The number of cycles required for failure is recorded as the fatigue life of the steel wire rod. To ensure accurate testing, multiple specimens are usually tested under different stress levels or load amplitudes. This allows for the determination of the fatigue strength of the steel wire rod, which is often expressed as the stress amplitude that can withstand a certain number of cycles without failure, such as 10^6 cycles. Overall, the rotating bending fatigue test provides valuable information about the fatigue resistance of steel wire rod, allowing manufacturers and engineers to assess its durability and suitability for various applications.

- Q: How is steel wire rod used in the production of wire harnesses?

- Steel wire rod is a crucial component in the production of wire harnesses as it is used to create the core structure of the harness. The wire rod is first shaped into the desired diameter and then further processed to remove any impurities and improve its strength and flexibility. This processed wire rod is then coated with various materials to enhance its durability and electrical conductivity. Once completed, the wire rod is used as the foundation for the formation of the wire harness, providing the necessary support and connectivity for the electrical components within the harness.

- Q: How are steel wire rods used in the production of wire cables?

- Steel wire rods are an essential raw material used in the production of wire cables. These rods are typically made from carbon or alloy steel and are formed into long, cylindrical shapes. They are then processed through various stages to transform them into wire cables. The first step in the production process involves hot rolling the steel wire rods. This process involves passing the rods through a series of rollers, which gradually reduce their diameter and increase their length. This hot rolling process helps to improve the ductility and strength of the steel, making it suitable for further processing. After hot rolling, the steel wire rods are then subjected to a process called cold drawing. In this process, the rods are drawn through a series of dies at room temperature, which further reduces their diameter and increases their length. This cold drawing process helps to refine the steel's surface finish and improve its mechanical properties, such as tensile strength and flexibility. Once the desired diameter and length are achieved, the steel wire rods are then used to produce wire cables. The rods are fed into a wire drawing machine where they are pulled through a series of dies to reduce their diameter even further. This drawing process helps to achieve the desired diameter and surface finish of the wire cables. After the wire drawing process, the steel wire rods are typically subjected to a heat treatment process to improve their mechanical properties. This process involves heating the rods to a specific temperature and then rapidly cooling them to achieve the desired hardness and strength. The final step in the production of wire cables involves stranding the steel wires together to form a cable. The individual steel wires are typically twisted together in a specific pattern, known as a lay, to provide the cable with the desired strength and flexibility. This stranding process is often followed by a coating or galvanizing process to protect the wire cables from corrosion. Overall, steel wire rods play a crucial role in the production of wire cables. They are transformed through various processes such as hot rolling, cold drawing, wire drawing, heat treatment, and stranding to create cables that are strong, durable, and suitable for a wide range of applications.

- Q: What are the common packaging materials used for steel wire rod coils?

- Packaging materials commonly employed for steel wire rod coils encompass wooden pallets, steel strapping, plastic wrapping, and metal sheets. Wooden pallets, serving as a foundation, are frequently utilized to stack and store the coils, ensuring stability and facilitating transportation. In order to prevent any movement or harm during transit, steel strapping is employed to firmly secure the coils together. To ensure the coils remain in prime condition, plastic wrapping is frequently employed to offer additional protection against moisture and dust. Occasionally, metal sheets are positioned atop the coils to provide supplementary safeguarding and prevent any external damage. These packaging materials are indispensable in guaranteeing the secure and efficient handling, storage, and transportation of steel wire rod coils.

Send your message to us

Wholesale 8.5mm steel wire rod in coils from Bao Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords