Raw Materials for Refractory:Whole Sale Good Quality Natural Flake Graphite FC 88 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape:powder

· Material: graphite

· FC Content (%): 87%min

· V.M Content (%): 2%max

· ASH Content(%): 10%max

· Moisture:1%max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Natural Flake Graphite

· Color:Black

· Size:-100MESH/200MESH/-325mesh or Smaller

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:powder

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

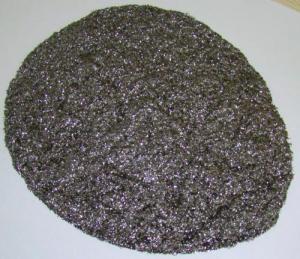

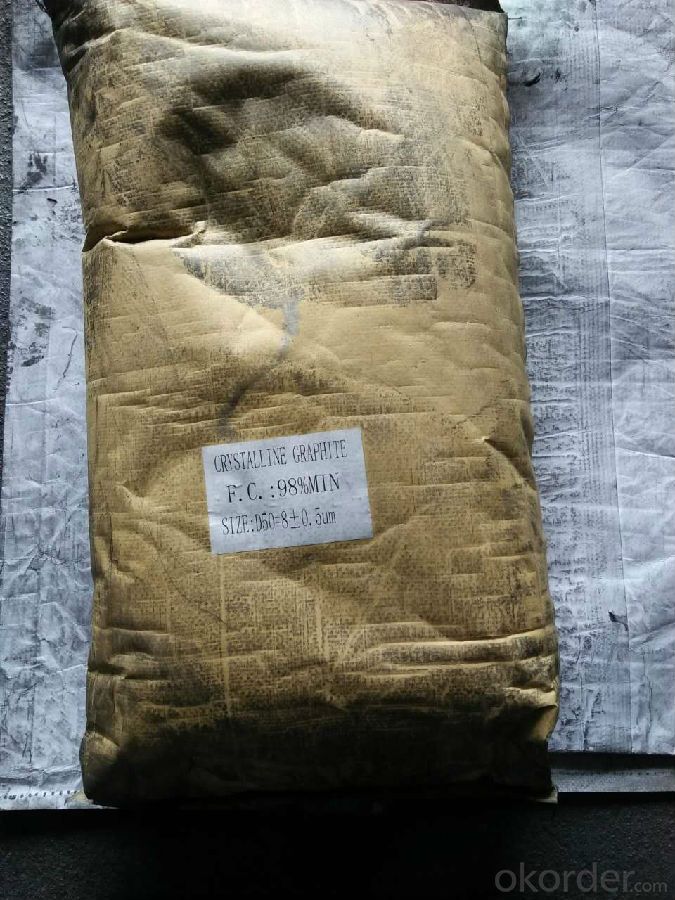

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: How to use fire-resistant soil?

- It can live with water, not too sticky. Don't be too thin. It's best to put the stove in the inner wall.

- Q: How long is the fire-fighting time of A class fire resisting window?

- Fire resisting window' duration of fire resistance: A class window, fire insulation ≥1.50h and fire resistance integrity ≥1.50h. Fire resisting window can be divided into three kinds: 一. window frame and sash framework adopt fire resisting window with steel manufacture ; 二. window frame and sash framework adopt fire resisting window with wooden manufacture; 三. window frame adopt steel and sash adopt wooden material or window frame adopt wooden material and sash framework adopt fire resisting window with steel material.

- Q: What are the characteristics of magnesium fireproof plate

- Glass magnesium fire resistance plate is fire proof, water proof, noise insulative, heat perservative, non-toxic and tasteless, corrosion proof, easy for construction, can be sawed and nailed and have a wide range of applications as well as long service life. These advantages allow it to be widely used in construction, decoration, fire protection and be the best material to replace is to replace plywoods, MDF, particleboard, gypsum board. It is a key environmental building materials recommended by national association of construction and decoration. 1 superior fire resistance performance. 2 weather fastness, long service life. 3. light weight and anti-seismic 4 high toughness, good impact resistance and compression resistance. 5 green and environmental 6 economical 7 sound insulative and heat insulative 8 convenient for processing and easy for construction.

- Q: How to divide the fire rating standards of insulation materials?

- 1. According to the GB8624-97 national standard, building materials can be divided into following levels in terms of combustion performance. A-level: Non-combustible building materials: Materials almost don't burn. B1-level: Fire-retardant building materials: Fire-retardant materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building materials: Combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. B3-level: Inflammable building materials: Inflammable building materials are highly flammable with no flame retardant ability. The fire risk is high. 2.The exterior wall thermal insulation materials can be classified according to fire rating. 1. Insulation materials with A-level combustion performance: rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. The insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powdery particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- 1. thermal insulation materials with A-level combustion performance: EPS sea capacity module, rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. thermal insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), phenolic aldehyde, gelatine powder polyphenyl granule,etc. 3. thermal insulation materials with B2-level combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc. Such A-level insulation materials are only fireproof, the thermal insulation properties are worse than that of organic XPS \\EPS materials. Currently I think that the best insulation material should be EPS sea capacity module, it not only achieves the requirement of insulation but also fulfills the goal of fireproofing, and the comprehensive unit price of it is not expensive. The thermal insulation materials in the domestic market have their own disadvantages, you'd better take the building demands into consideration, and use the materials that are within the acceptable range. I hope my answers help you.

- Q: What is the material composition of the new fire-resistant coating?

- New fire?retardant?coating materials are produced by non-toxic expanding materials and special process, with no pollution. Use natural bite when installing, without using the formaldehyde and other toxic glue. It consists of a variety of organic matters, so it adapts to the natural environment, with long time of fire-resistant; The fire-resistant time for new fire retardant module is up to 4 hours or more, three hours more than the standard prescribed by the state. It is composed by the specially formulated materials, with no flying smoke, good heat insulation effect, fast heat dissipation, scientific and rational design, easy using and no falling off and long period of effective.

- Q: What refractories can withstand high temperature above 2100 degrees?

- But the price is more expensive, while the insulation performance is not as good as common materials. Is there a material that can withstand 2100 ℃? Currently, the long-term use temperature of the best refractory bricks is about at 1800 ℃, while materilas that can withstand a temperature of 2100 ℃ are relatively rare in the production.

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Classified into ordinary and special refractories. The ordinary refractory material is calssified into acid, neutral and alkaline according to the chemical property. Special refractory material is calssified into high temperature oxide according to the composition for , infusible compound and high temperature composite in addition, can be divided into ordinary refractory products according to the fire intensity (1580 ~ 1770 DEG C), high-grade refractory products (1770 ~ 2000 DEG C) and special refractory products (2000 DEG C above). According to the products shape can be divided into bulk (standard brick, special-shaped brick block, special shape (crucible, sagger, pipe, etc), fibrous shape (silicates of aluminum and zirconium oxide and boron carbide matter) and irregular shape (fireclay, refractory castables and incompletely material).

Send your message to us

Raw Materials for Refractory:Whole Sale Good Quality Natural Flake Graphite FC 88 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords