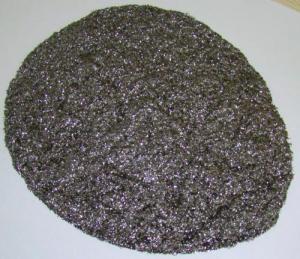

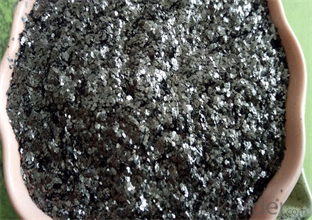

Raw Materials for Refractory:Natural Flake Graphite FC 89 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape:powder

· Material: graphite

· FC Content (%): 89%min

· V.M Content (%): 2%max

· ASH Content(%): 9%max

· Moisture:1%max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Natural Flake Graphite

· Color:Black

· Size:-100MESH/200MESH/-325mesh or Smaller

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:powder

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q: hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q: Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- The fire resistance rating of the aluminium-plastic?panel is determined by two indicators, namely national compulsory standard of GB8624 "Building Materials Combustion Performance Grading Method ", and GB/T17748 "Aluminium-plastic?Composite Panel National Standard" . Classifications of combustion performance of building materials in our country are as follows: A class: Incombustible building materials; B1 class: Flame-retardant building materials; B2 class: combustible building material; B3 class: flammable building materials. The fire resistance rating of the aluminium-plastic composite panel shuld be no less than B1 class. 1. Detection indexes and requirements of fireproof aluminum-plastic composite panel (B1 class): (1) Conduct the test according to GB/T8625-88, the average leftover length of each test specimen should be more than 150mm, (any test piece should have leftover length), and the maximum average flue gas temperature of each test should be no more than 200 ℃; (2) Conduct the test according to GB/T8626-88, flame hight indicators.

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: which kind of refractory is commonly used in the industry

- Like silicon, magnesium calcium and metallurgy refractories, glass, silicon, etc., knowing the basic materials, and the businesses are not the same. I suggest that you can buy the refractory book to read.. Others include zircon, shapeless refractory material and so many other cement, such as magnesia, high alumina,ect.. Iron making is using the acidity material, continuous casting is using the clay, nonferrous metals and other types of more complex hot-press charcoal; steel making is using the alkaline, magnesium chrome, magnesium carbon, and clay,etc..

- Q: what are the types of piping insulation material fire?rating?

- There are two grades: 1, the organic material: Grade B Grade B1 hard combustion (fire?retardant) 2, inorganic materials: class A no burning it is divided into three levels, attributed to the types of materials!

- Q: Development trend of refractory industry

- In the central provinces in Henan, Shanxi, Liaoning China main manufacturer of refractory material, which is the main origin of three China bauxite, magnesite and other refractory materials; refractories industry by the end of May 2009 more than 3236 enterprises; industry revenue reached 67 billion 52 million 540 thousand yuan, Henan Province, Liaoning, Shandong, Jiangsu, Hebei and other regions, and refractories industry in the development of better leading enterprises, such as blue and white, accessible, prco etc. at present, its sales in the industry in the proportion is still small, the largest sales is also inadequate in refractory industry in 4%. An enterprise should play a leading role in leading enterprises in the industry, and its turnover in the industry should be more than 15%. Obviously, at present the refractory industry in the leading enterprises do not have, and the refractory industry concentration needs to be improved, and the existing resources in the refractory industry integration, is undoubtedly the way this process effective and efficient.

- Q: How many levels are there in the classification of PP fireproof materials?

- PP fireproof materials level V-0: After two 10-second fame tests on the sample, the flame extinguishes within 30 seconds. Inflamer can not drop. V-1: After two 10-second flame tests on the sample, the flame extinguishes within 60 seconds. Inflamer can not drop. V-2: After two 10-second flame tests on the sample, the flame extinguishes within 60 seconds. Inflamer can drop.

Send your message to us

Raw Materials for Refractory:Natural Flake Graphite FC 89 with Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords