PVC Ceiling Trinidad San Juan - White & Wood Color PVC Ceiling Price, PVC Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

PVC Ceiling for Interior Decoration

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel with high quality and competitive price. And monthly output up to 480,000 Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Specification:

1) Easily installation,surface is smoothness,flatness,without gap when concatenated.

2) High intensity,good quality,not easy to deformation,resist erosion,mothproof,sound insulation,waterproof,fireproof,aging-resisting,durable.

3) It can be processed by drilling,sawing,nailing.Hot bending,hot-folded.

4) Interior decoration for ceiling,wall.Easy cleaning,healthy and environmental.

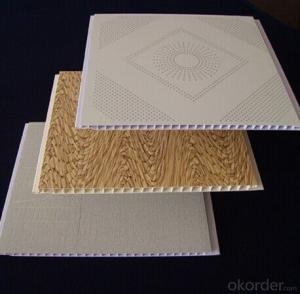

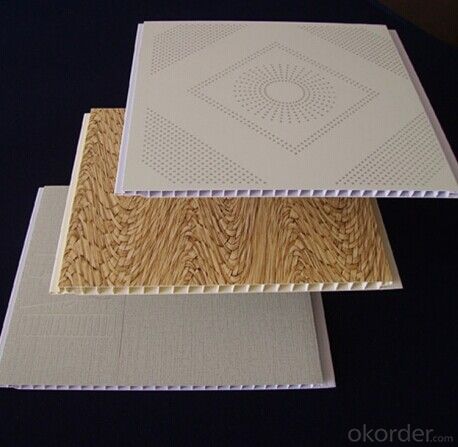

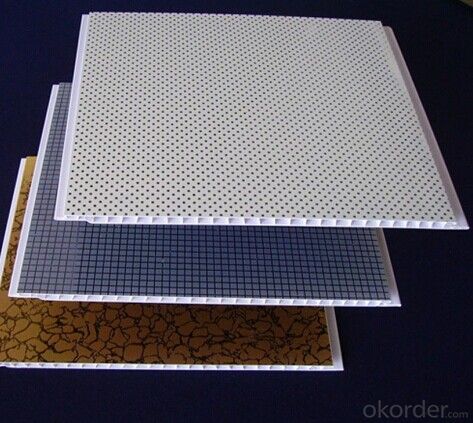

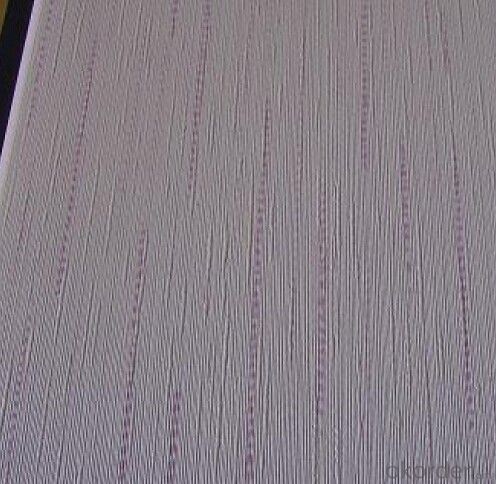

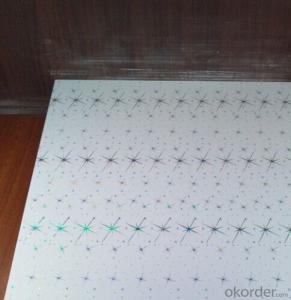

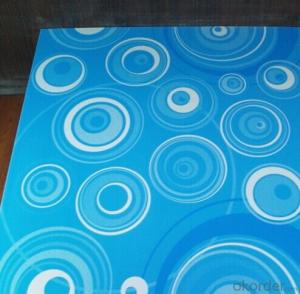

3.Image

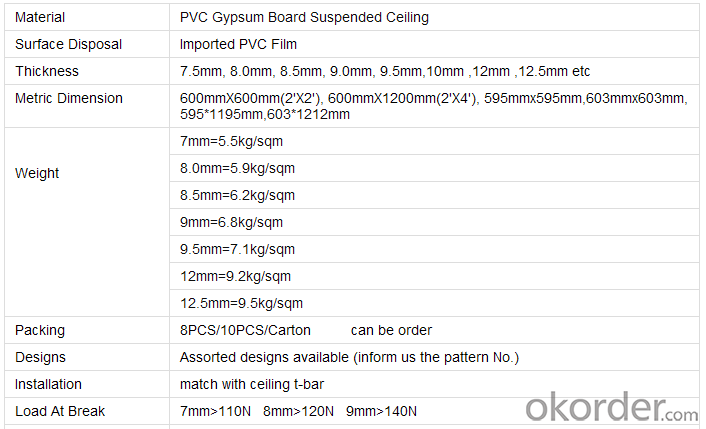

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

Width: 180mm/200mm/250mm/300mm/595mm/600mm as customers' requirement

Thickness:4mm/4.5mm/6mm/7mm/7.5mm/9mm/10mm/11mm/12mm / as customers' requirement

Length: 2m~5.95m or as customer's requirements

PVC content :30%-70% as your request

Weight: 1.6kg/sqm,2kg/sqm,2.3kg/sqm,2.8kg/sqm,3.55kg/sqm,4.6kg/sqm or as your request

Raw materials: PVC resin and calcium carbonate

Color: hundreds of colors and patterns or according to your specific designs

Ceiling tile shape: rectangle

Surface treatment: Normal printing,Hot printing,Normal transfer,Laminated,High glossy

Function: Moisture-Proof, Mould-Proof, Smoke-Proof, Sound-Absorbing, Waterproof

Feature: Artistic Ceilings, Integrated Ceilings, Perforated Ceilings

Certificate:ISO9001 ,CE , SONCAP ,TUV,BV, QC

Packing detail:10pcs/ PE film or Carton

Delivery detail:In 10 days for 1*20'GP,15 days for 1*40'GP/HQ.

Made of Waterproof. fireproof, Durable PVC Plastic

Suitable for Bathrooms, Showers, Wet Rooms Kitchens and More

Features: (1) Easy to install and clear

(2) Variety of colors and patterns or as your request

(3) High intensity, resist erosion, auti aging

(4) Fireproof, waterproof, environment friendly

(5) High quality, good service and good price

- Q: What is the difference between oak bathroom cabinet and PVC bathroom cabinet?

- This is two different materials, completely two styles.

- Q: Home decoration with PVC buckle hanging crane top, want to buy crystal lamp, but do not know whether the pvc Kouban can withstand the weight of crystal lamp!

- I am learning to build, pvc is polyvinyl chloride

- Q: Pvc board and fire board glue what glue?

- Due to the waterproof performance of the fire board is very good even the big white scraping in the above are not easy to fall but the effect is more fishing solid smooth, with ordinary brother two good or other glue can be very good paste together.

- Q: Introduce the characteristics of PVC sheet characteristics?

- With the MDF as the substrate, the surface smoothness is good, easy to do modeling, can be engraved milling pattern, the surface with imported PVC veneer by hot pressing, PVC molded plate with rich color, unique shape of the advantages of plastic door four Board sealed into one, do not need to edge, to solve the edge of a long time may be open when the plastic problem. Foreign called "no defective plate" its thickness of 0.6MM and 1MM two.

- Q: Wood-plastic board, PVC board, science and technology What is the difference between wood?

- Wood-plastic board is made of wood fiber mixed polymer plastic after extrusion molding, is an environmentally friendly material, its weather resistance is very good, generally used for outdoor decoration. Pvc board is made of pvc material of a material, it is light weight, have a certain strength, but the weather resistance of acid and alkali difference for product packaging and interior decoration. Science and technology wood is made of artificial veneer made of decorative panels, generally with no color, pattern and other natural decorative panels can not achieve the decorative effect, but its pattern rigid, color frivolous no less than the natural decorative panel texture and decorative grade.

- Q: Has anyone tried this? I need to use it for a window that is 8'4 wide and due to the construction of the ceiling (concrete) and window frame (metal) I can't put in any center support. What diameter pipe did you use and what is the width of the window you used it on? Any tips/tricks?

- bad choice, the PVC will give more then a metal rod, select a metal curtain rod and use self tapping screws to mount your support bracket on the metal frame.

- Q: Pvc foam board and wood-plastic plate difference?

- Pvc foam board and wood-plastic plate difference? The former is the gas plate, which is a solid plate; the former can not hollow, the latter can!

- Q: What is the advertising AD board material

- AD board, is the Andy board it ... Andy board, also known as PVC board, the main material is PVC, popular point is plastic. The If it is not sure you can touch the material, if it feels soft and flexible, like lunch box lunch box, that is the KT version; if it is hard, touch like a plastic pipe, that is Andy board The The If you are not sure, watch the surface. Look carefully, the general KT version of the screen are uneven, bumps and small bubbles; and Andy board because of the relatively hard, relatively smooth surface. The If it is not sure, look at the amount of price. General 5mm Andy board than 5mmKT board heavier, and more expensive, is several times the KT version. The If still can not be sure, then on top to let the descendants continue to put up the floor ...

- Q: a restaurant that is partailly elevated. Is heat tape 'really' nessessary? If I wrap it tightly with insulatin then wrap it again with a plastic flex wrap, that ought to be okay, right? I'm not a plumber- just a basic maint. man. Any tips, ideas?

- Are you sure you mean drain pipes ? There is absolutely no reason to insulate drain pipes and definitely no heat tape .

- Q: PVC can use 502 glue it?

- Need to use PVC special glue, building materials shops have to sell, because 502 is an instant adhesive, if smear less, may leak, and if smear more, it can not do "instant" bonding. PVC glue dry up quickly, as long as the preparatory work done in advance, an hour is enough - simply do not take an hour.

Send your message to us

PVC Ceiling Trinidad San Juan - White & Wood Color PVC Ceiling Price, PVC Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords