Plastic Sheets - White PVC Form Board Waterproof Fireproof 1mm 2050*3050mm

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Waterproof Rigid PVC Foam Board

Product Description

Width: 2050mm

Length: 3050mm

standard size :2050*3050mm

NOTE: we can make other size according customer requirment

payment | L/C,T/T |

Delivery | 6-9days after confirm your order |

PVC foam board/sheet description

1 | Product | PVC Foam sheet |

2 | Standard size | 2050mm × 3050mm |

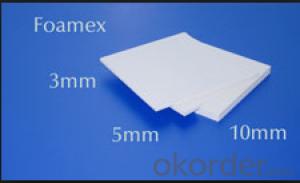

3 | Thickness | 1mm |

4 | Density | 0.8g/cm3 |

5 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

6 | Executive standard | QB/T 2463.1-1999 |

7 | Certificate | ISO、SGS PONY Cetification |

8 | Weldable | Yes |

9 | Foam Process | Celuka |

10 | Packing | Carton box or wooden pallet packing |

11 | production capability | 500000 pcs per month |

12 | Life Span | >50 years |

13 | Flame retardance | self-extinguishing less than 5 seconds |

Application

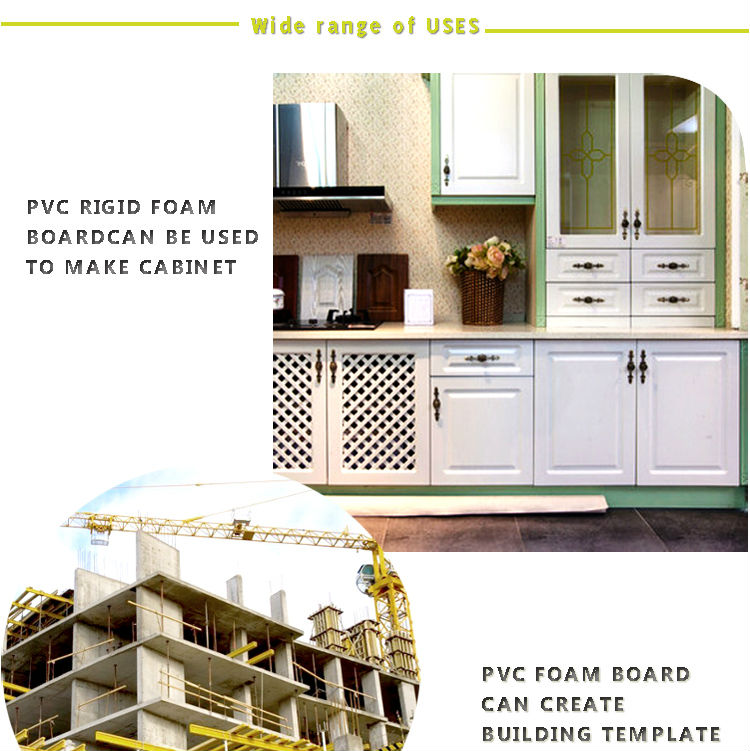

1. Advertisemen Board and sign board

2. the advertisement sheet for printing,engraving,cutting,sawing

3. Architectural decoration and upholstery

4. decoration for partition wall and shopwindows

- Q: Are plastic sheets suitable for shower splashbacks?

- Yes, plastic sheets are suitable for shower splashbacks. They are waterproof, durable, and easy to clean, making them a practical choice for protecting walls from water splashes in the shower.

- Q: Can plastic sheets be used for automotive applications?

- Yes, plastic sheets can be used for automotive applications. They are commonly used for interior components such as dashboards, door panels, and seat backs. Additionally, plastic sheets are used for exterior parts like fenders, bumpers, and trims. Plastic sheets offer advantages such as lightweight, durability, and flexibility, making them suitable for various automotive applications.

- Q: Sharp has plasmacluster technology (+ - ion) honey comb dedorizer to kill germs,mouls get rid of bad fishy smell.Mitsubishi has vitamins making factory to keep veg fresh so asToshiba has hybrid Plasma dedorizer doing the same function.Then there is Hitachi w. nano titanium technology.Yet Samsung also has nanotechnology.Too many to choose from.By the way 3 door fridge is better than a 2 door fridge ?

- if ur looking for kites you fly, try dollar tree or dollar store.

- Q: I got a protective plastic sheet, but every time I try to put it on, a million bubbles keep popping out.

- Unfortunately, it's not really possible to eliminate every bubble. Just put it on very slowly and try to rub them out as you go instead of trying to get them all at the end. Keep in mind that when the iPod is turned off, the bubbles look horrible but once it's turned on, you won't notice them nearly as much.

- Q: In home improvement, what is the best material used in the kitchen ceiling, aluminum gusset is good, or PVC plate or aluminum plate?

- Relative to this problem, the aluminum gusset plate does not need to use any wood in the installation process, is more suitable for the moist environment suspended ceiling.

- Q: name of toy that heated plastic sheets into forms and shapes?

- Vac-u-form

- Q: Are plastic sheets resistant to scratching from abrasive materials?

- Yes, plastic sheets are generally resistant to scratching from abrasive materials due to their durable and tough nature.

- Q: About a metre square, by about 7mm thick.

- I'm in the US... but a quick google search showed: 6mm X 2440mm X 1220mm CayGlass Acrylic - ?77.91 (?91.54 IncVAT) The supplier had nothing thicker than 6mm They are C

- Q: Can plastic sheets be used for interior design purposes?

- Yes, plastic sheets can be used for interior design purposes. They are versatile and available in various textures, colors, and patterns, making them suitable for applications such as wall coverings, room dividers, furniture accents, or even lighting fixtures. Additionally, plastic sheets are often more affordable and easier to install or maintain compared to other materials, offering designers a wide range of creative possibilities for interior design projects.

- Q: Lets say person A buys 2 tabs of acid, puts it in a plastic baggy, and inserts in pocket. Is there any chance of the lsd bleeding through the plastic and being absorbed into person A's leg?

- No, there is far too little LSD to be absorbed. Plus plastic barrier will act as a barrier.

Send your message to us

Plastic Sheets - White PVC Form Board Waterproof Fireproof 1mm 2050*3050mm

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords