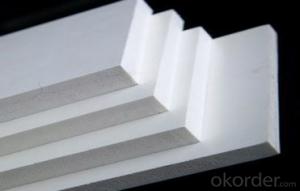

PVC Foam Board PVC Foam Sheet PVC Foam Panel Ex-cel PVC Free Foam Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: I have construction happening in my apartment, and I would like to protect my furniture. I am not sure what to call the plastic that I need to buy to protect my furniture. I am also not sure where to buy this plastic. Help please....

- cheap plastic tablecloths from the dollar store will work fine for most of your things. It's easier to seal off an area with the plastic things you can buy to put on windows for the winter. They come in sliding door sizes and completely seal the doorway from any dust getting in.

- Q: How thick can plastic sheets be?

- Plastic sheets can vary in thickness depending on the specific type of plastic and its intended use. However, in general, plastic sheets can range from being extremely thin, as thin as a few micrometers, to several centimeters thick.

- Q: Are plastic sheets resistant to cracking in freezing temperatures?

- Yes, plastic sheets are generally resistant to cracking in freezing temperatures.

- Q: Can plastic sheets be used for art and crafts?

- Yes, plastic sheets can definitely be used for art and crafts. They are versatile and can be easily cut, shaped, and molded to create various art pieces, such as sculptures, mobiles, stencils, and even jewelry. Plastic sheets also come in different colors and transparency levels, allowing artists to experiment with different effects and techniques. Additionally, they are durable and lightweight, making them suitable for a wide range of craft projects.

- Q: Pink fiberglass insulation comes either faced or unfaced. On DIY shows on TV, I almost always see people using unfaced insulation and putting a sheet of plastic visqueen over the studs, rather than using faced insulation and not needing visqueen. Which method is better?

- For the best answers, search on this site https://shorturl.im/axL54 Hello You have asked this question twice. If you do not install a good vapour barrier on the warm side of your insulated wall, the insulation will become saturated with moisture and cause rot and mold. All the work you have done will have to be re-done in 3 to 5 years. Use acoustical caulking on the studs and top and bottom plates before applying the 6mm vapour barrier. Place the vapour barrier over the studs and staple. The acoustical caulking is messy but essential to seal holes created by screws/nails when installing interior finish such as drywall, plywood, etc. You can cut out 2 foot square pieces of vapour barrier and wrap your electrical boxes with them - tuck the excess inside the box. When the vapour barrier has been installed cut an X (opposite corner to oppostie corner) over each box with care not to damage the wiring. Pull out the plastic tucked into the boxes and lay it out on the vapour barrier - seal it with acoustical caulking. this gives you a unbroken vapour barrier over the whole wall surface. This is not controversial if you talk to reputable contractors. Your building codes likely call for this type of installation. Good Luck

- Q: I am making a craft project. I went to a craft store and purchased a yard of plastic in the fabric dept. I cut two 6X6 pieces and glued them with a water resistant glue. I allowed 24hrs. I then put water inside and a few hrs later noticed it was soaking through the plastic and leaking. I need a glue that will hold water inside. I hope this clarifies my question.

- For the best answers, search on this site https://shorturl.im/axp3t Not knowing what type of plastic it is, the only two glues that may work are; Superglue; if it doesn't work, then try; PVC plumbers glue. Both can be purchased at a Big Box home Improvement Store for cheapest prices, or your local hardware store. Vapors from the PVC glue are flammable and toxic, so use in a well ventilated area only. Work safe, be safe. Good Luck with the project.

- Q: The one that is thicker than sliding folders. And in different colors.

- This Site Might Help You. RE: Where can I buy polypropylene plastic sheets here in Cebu, Philippines? The one that is thicker than sliding folders. And in different colors.

- Q: Are plastic sheets resistant to static electricity?

- Yes, plastic sheets are generally resistant to static electricity.

- Q: Can plastic sheets be used for insulation against noise?

- Yes, plastic sheets can be used for insulation against noise. Plastic sheets such as PVC or acrylic can help reduce noise transmission when properly installed and combined with other soundproofing materials. They help create a barrier that absorbs and blocks sound waves, reducing the amount of noise that passes through.

- Q: I'm using it to make a model, so I only need a small sheet, nothing industrial in scale. A place to buy it near downtown LA would be optimal. From what I've found, the material is known as corrugated plastic or hollow board in some places.

- Some where between 25 30 I stopped looking forward to an age.

Send your message to us

PVC Foam Board PVC Foam Sheet PVC Foam Panel Ex-cel PVC Free Foam Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords