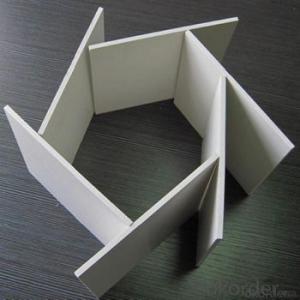

PVC Ceiling Boards - White PVC Foam Board in Heat Insulation and High Density for Builders Warehouse

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

white pvc foam board in heat insulation and high density

Product Introduction

a kind of high-tech product, is produced by special machinery and technology processing, has excellent corrosion resistance, insulation, and have a certain mechanical strength. The main material new PVC resin can be foamed and extruded into a special sheet with many advantages and uses wildly. It's a good substitute for wood.

Product Specification

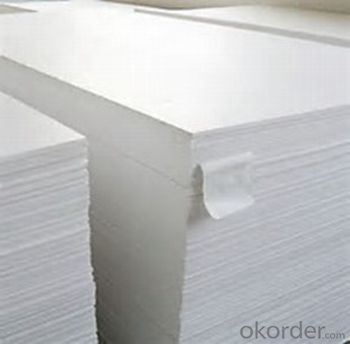

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | TSC |

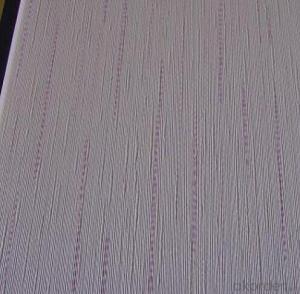

6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

7 | Executive standard | QB/T 2463.1-1999 |

8 | Certificate | ISO |

9 | Weldable | Yes |

10 | Foam Process | Celuka |

11 | Packing | Carton box or wooden pallet packing |

12 | production capability | 10000 pcs per month |

13 | Life Span | >50 years |

14 | Flame retardance | self-extinguishing less than 5 seconds

|

3. Why Choose us

1. we have our owned pvc foam sheet factory located , China's most popular pvc sheet production area, which make sure the production ability and products high quality.

2. our office located in Beijing , the capital of china , it makes us to keep in touch with buyers timely and very convenient for business talking in our office

3. our overall different department makes us the high standard of working efficiency. such as our solid financial deparment, sales department, documents department and logistic department .

FAQ:

1. Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

2. Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

3. Which Payment Terms?

ALi Trade Assurace, T/T(Telegraphic Transfer), West Union, L/C etc.

- Q: Pvc buckle board ye demolition?

- Long strip pvc buckle plate is so demolished: First of all, look at the installation when the pvc board and repair corners have not hit the glass glue, if the fight, it cut it with an industrial knife. And then put the word screwdriver or utility knife inserted in the last piece and the penultimate gap, gently swing up and down, while the last piece of pvc board is loose, then the board to the left or right side of the corner Push, there will be one side down, and then grabbed the side with both hands, gently down a pressure, slightly with the point of force, a pull, came out. And then dismantling the inside of the board, it is necessary a cross screwdriver, and because each piece of pvc board will be on the tapping of the screw, the first under the self-tapping screws, and then slowly demolition, do not break. Finally, open the pipe hole, the first to remove the board according to the direction of the release, (must be according to the direction) Oh, and then need to smoke pipe hole place to mark, and then buy the smoke pipe vertically on the mark, With paint strokes along the smoke pipe draw a circle, and then open the hole hole. Do a good job after the original path installed, surrounded by a good glass glue, on the line.

- Q: Pvc board ceiling installation method which know? How much is the installation cost?

- 1, according to the design elevation in the wall around the wall, the ball line should be clear, accurate location, the level of tolerance ± 5mm. 2, along the elevation line fixed edge keel, the role of the keel is the edge of the ceiling seal, side keel commonly used specifications for the 25 * 25mm, the color should be the same with the PVC buckle, the keel with cement nails fixed on the wall. The following are the same as the " 3, to determine the keel position line, because each piece of PVC gussets are already forming decorative panels, generally can no longer cut block, in order to ensure the integrity of the ceiling and installation reliability, according to the size of aluminum plate, and The size of the ceiling to arrange the structure of the ceiling skeleton size. The basic layout of the PVC gusset finishes is: the plate combination to be complete, surrounded by the edge, the edge of the edge to be symmetrical, will arrange the layout of the dragon frame line drawn on the top of the line. The following are the same as the " 4, the main keel hanging point spacing, according to the design recommended series selection, the middle part should be arch, keel arch height is not less than the room surface span of 1/200. The main keel should be installed in time to correct the location and height. To control the formation of the dragon frame, first of all should be pulled out of the vertical and horizontal elevation control line, starting from one end, while the side of the installation to adjust the boom suspension height. To be a large flat, and then some of the curved Alice of a single keel to adjust until the smooth meet the requirements so far.

- Q: PVC plastic plate is environmentally friendly

- PVC plastic plate processing need to join the stabilizer and other additives, if the stabilizer in lead, barium, chromium and other heavy metals exceeded, it is considered not environmentally friendly, but now the domestic heavy metal detection is not very strict

- Q: What is the difference between oak bathroom cabinet and PVC bathroom cabinet?

- This is two different materials, completely two styles.

- Q: What is the difference between WPC and PVC flooring?

- WPC refers to the wood-plastic composite flooring, may be PVC / PE / PP + wood powder made out. PVC is PVC plastic, ordinary PVC flooring may not add wood powder.

- Q: Pvc board in the outdoor high temperature with what glue is good

- Pvc board in the outdoor high temperature can be used HY-108AB glue bonding, the highest resistance to 200 degrees.

- Q: across ceiling joists and then down 12 feet to a generator. I live in a town of 50,000 and it may or may not be union labor

- PVC is not allowed by code for a gas line. It is too easy to break, from an earthquake or other physical abuse. You need to use black iron pipe or the newer flexible pipe systems that have become available. The cost depends upon local labor conditions and how difficult the attic access may be, but a ballpark price might be $1000.

- Q: Pvc clean sheet is what material

- Is the PVC plastic plate

- Q: Pvc floor ok how is it compared to solid wood flooring?

- Solid wood flooring from ancient times to the people are the first choice for decoration, because the solid wood flooring is very nice decoration. Feet comfortable, decorative style retro, serene, very warm. But the disadvantage is that more and more expensive wood, wood materials are afraid of water, fear of water, easy to dry, easy to borers and other shortcomings. Fortunately, there are new pvc floor. This is from the eighties into the domestic market. Has a lot of traditional flooring has no advantages, to overcome the shortcomings of the traditional floor.

- Q: What is the difference between acrylic and PVC? Which is relatively better?

- 1. From the color points, PVC board stability is poor, easy to decompose when processing, generally with the same color of the acrylic than the background will be yellow. 2. From the density of points, PVC board density 1.35-1.4G / CM3, acrylic 1.1G / CM3, if the thickness and size of the same plate, heavier on the PVC. 3. Listen to the sound, with the area of almost two boards, to the floor light wrestling or hand percussion, sound crisp is the acrylic. Dull is PVC. 4. is burning smell smell. Acrylic burning flame yellow, alcoholic and smoke-free. While the flame when the PVC board was green, with hydrochloric acid smell, take white smoke.

Send your message to us

PVC Ceiling Boards - White PVC Foam Board in Heat Insulation and High Density for Builders Warehouse

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords