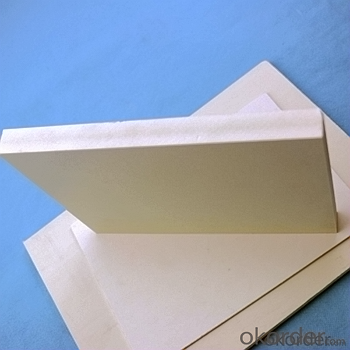

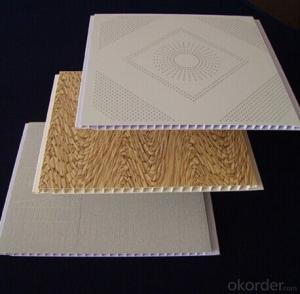

White PVC Ceiling PVC Free/Crust Foam Board for Furniture and Construction with Different Density

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC Free/Crust Foam Board

1. Product Introduction

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

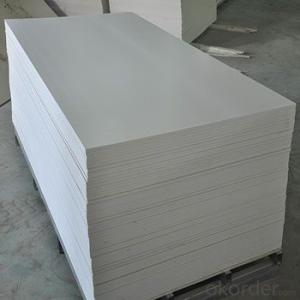

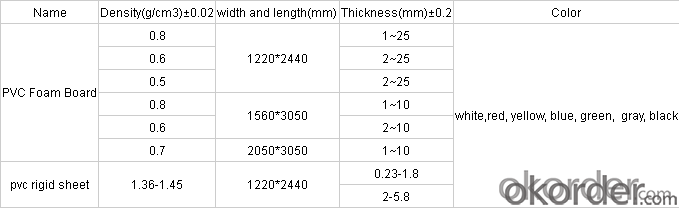

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

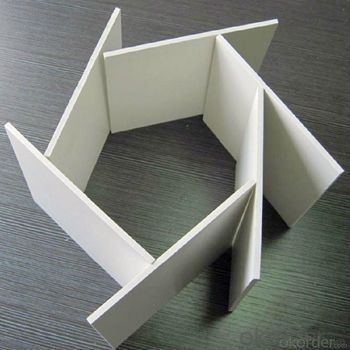

3.Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

4.FAQ

1, How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect

2, Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

4. Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

Answer :we are manufacturer specializing in stationery and plastic packing products in highly quality and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,packages of cosmetic and other daily necessities, they are mainly famous ,such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

- Q: Buy pvc floor need to pay attention to what ah?

- A smell, two pull, three pinch, four strokes, five look, six comparison A smell of the product there is no pungent odor, the body is the revolutionary capital, not environmentally friendly products can not be used, some environmentally friendly products manufacturers or distributors will be small to say (how many have some taste, in other words is actually There is a smell, it may be great but not he said a bit) Two pull: pull a floor to see if it is not easy to deformation, or even be broken off Three pinch: with your fingers belly pinch the floor to see if the floor will be squeezed out of a pit, and a long time not play, or very hard simply pinch, pinch no flexibility, if the pinched , Or no flexibility are poor quality poor quality products, good PVC plastic sports floor should have a good rebound, good rebound will feel comfortable, in order to better protect the athletes. Four strokes: to find a hard object, such as the key lighter what on the floor surface to draw a look at the floor surface will not hurt, and the degree of damage. Can be very good to see the floor of the wear resistance. Five to see: look at the appearance of the product, with or without color, delicate or rough, take a look at the official test report and test reports in the parameters to see if there is any patent (such as double suction anti- Whether the patent certificate and the authenticity), take a look at the project case, take a look at the user's evaluation (good reviews are objective look) and so on. Six ratio: to be a comprehensive comparison, the saying goes to shop than three do not suffer, not afraid of the goods are afraid of goods than goods.

- Q: PVC board how rub rub

- PVC style, rich colors. Giving a stylish, crisp feeling. Suitable for young married couples to use.

- Q: Allow phonetic typing Pvc panel market now how to? Want to do the next trade. Please help me find this station?

- your question is total garble what are you looking for ? try your search bar and learn to make a complete question

- Q: Engaged in the wedding industry, want to wedding photos (generally 60cm * 90cm or so) of the backplane into a polymer material, and now the backplane is generally made of wood, with crystal to seal the photos on the board, do not know PC board, PP board, PE board, PVC board, ABS board, etc., for which polymer material is good, mainly can not bend, not easy to deformation, hardness slightly higher, as well as consider the cost, which board is more suitable? Seeking

- These have an expansion rate, not suitable for use in the frame, I suggest you use the wood plastic, invariable, super strong, the price depends on your bargaining power, and the other with their own not much, so it does not matter

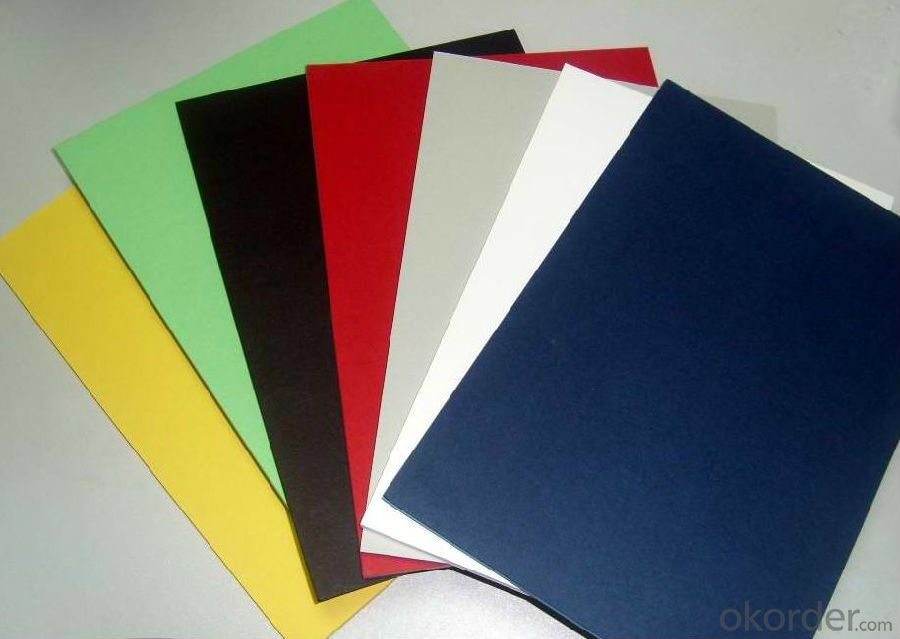

- Q: Colored PVC board is what kind of board ah, can not paint

- There are many types of colored PVC board. 1, advertising with the PVC plastic plate; 2, PVC surface paint board; this PVC board is no need to paint, because their material color and texture there are many, the paint is not necessary. And this PVC board surface will generally glazed, paint up the durability will not be durable, will be from the skin, rupture and so on.

- Q: Pvc board ceiling how much manual

- Now about 40 yuan per square meter.

- Q: Hollow engraved high density board and PVC which is good

- Hollow carved flowers

- Q: How heavy the pvc board hangs on the wall

- With a large core board made of cloth made of a fake wall in the cloth with a nail nail lap

- Q: Installation works PVC wire tube castable board inside the plugging dredge there to sell?

- In the construction process, there are often pre-arranged lines PVC pipe is blocked by concrete and can not successfully threading the situation , In the process of dredging, often can not accurately find the location of the clogging and waste of human, material, financial, time, and even delay the duration. This is the most troublesome thing to install the construction workers!

- Q: PC board PV board PVC board PPV board distinction and use

- Pvc board generally used with the bathroom and kitchen, the other two I am not very clear. But home improvement using PVC board more.

Send your message to us

White PVC Ceiling PVC Free/Crust Foam Board for Furniture and Construction with Different Density

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords