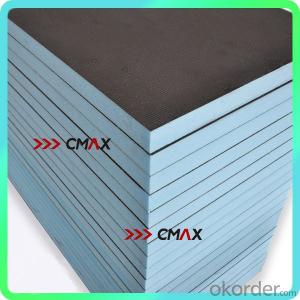

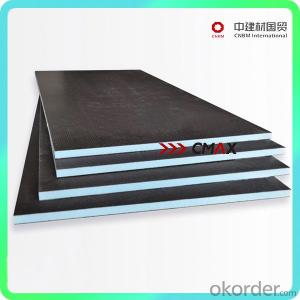

XPS Extruded Polystyrene Board - Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | XPS.S-JSB | compressive strength: | min.300Kpa | thermal conductivity: | 0.029-0.036W/M.K |

| material: | xps/eps, synthetic mortar | XPS color: | pink, blue, green |

Packaging & Delivery

| Packaging Detail: | 6mm: 20pcs/carton 10-20mm: 10pcs/carton 30-80mm:5pcs/carton |

| Delivery Detail: | WITHIN 25 DAYS AFTER RECEIPT OF THE DEPOSIT |

Specifications

1.cement&glass+XPS+cement&glass mesh

2.size:1200-2500 L*600-1200 W *6-80mm T

3.CE approved

4.waterproof

5.light,easy install

Insulated Fiberglass tile backer boards are made from extruded polystyrene and finished both sides with a synthetic mortar reinforced with a glass fibre mesh. It is ideal for wet-zone and damp zone in a bathroom, washroom and shower area.

Characteristics:

1. Moisture and rot proof

It is ideal for bathrooms, showers and wetrooms, suitable for exteiror use.

2.Exceptional Stability

Eliminates the common cause of tile failure associated with mdf, chipboard, plywood, plaster and plasterboard.

3.High thermal insulation

Helps reduce heat loss. Recommended and suitable for use with all types of electrical underfloor heating.

4.Light weight and workable

Easier and faster to work with than all other type of building board.

5. Replace wet finishes

Can be used in place of floor screeds and rendered/plastered all finishes. Fast-tracks tiling and save costs.

Boards open up a whole new range partitions of any shape and design in minutes. This eliminates expensive labour costs and provides the ultimated substrate ready for both tile fixing or render finishes. It is easy for a person to do single handed as the boards are lightweight and very easy to cut with a saw or knife. Shield Waterproof Insulation board makes it easy to create a fully waterproof wetroom, covering the walls, floors and shower area.

XPS.S-JSB Sizes

Item No. | Length (mm) | Width (mm) | Thickness (mm) | Weight per sheet (kg) |

XET-J01 | 1200 | 600 | 6 | 2.0 |

XET-J02 | 1200 | 600 | 10 | 2.2 |

XET-J03 | 1200 | 600 | 12 | 2.3 |

XET-J04 | 1200 | 600 | 20 | 2.5 |

XET-J05 | 1200 | 600 | 30 | 2.7 |

XET-J06 | 1200 | 600 | 40 | 3.0 |

XET-J07 | 1200 | 600 | 50 | 3.3 |

XET-J08 | 1200 | 600 | 60 | 3.6 |

XET-J09 | 2500 | 600 | 10 | 4.6 |

XET-J10 | 2500 | 600 | 12 | 4.8 |

XET-J11 | 2500 | 600 | 20 | 5.2 |

XET-J12 | 2500 | 600 | 30 | 5.6 |

XET-J13 | 2500 | 600 | 40 | 6.3 |

XET-J14 | 2500 | 600 | 50 | 6.9 |

XET-J15 | 2500 | 600 | 60 | 7.5 |

We also can provide customized dimensions on request.

XPS.S-JSB Technical Data

Thermal conductivity, 90 days, 10°C | GB/T10294 (EN13164) | 0.030-0.036W/(M.K) |

Compressive strength at deformation of 10% | GB/T8813 (EN826) | Minimum of 300Kpa |

Bond Strength | N/A | 0.3N/mm2 |

Maximum tile loading weight | N/A | 60kg/M2 |

Bending Stiffness (20mm) | ASTM C203 | 2.00Mpa |

Moisture permeability | GB/T2406 (DIN EN 12086) | 3.2m |

Dimensional Stability | N/A | ≤1.0 |

Working temperature | N/A | -50°C-80°C |

Other Data of XPS.S-JSB

Insulation Board Thickness (mm) | XPS thickness (mm) | R-value (m.k/w) | Heat transmission coefficient at 10°C (W/ M2XK) | Heat transmission coefficient at 10°C (W/ M2XK) |

6 | 5 | 0.16 | 3.19 | 3.54 |

10 | 9 | 0.28 | 2.33 | 2.52 |

12 | 11 | 0.36 | 2.69 | 2.06 |

20 | 19 | 0.59 | 1.40 | 1.46 |

30 | 29 | 0.91 | 0.99 | 1.03 |

40 | 39 | 1.22 | 0.75 | 0.80 |

50 | 49 | 1.53 | 0.62 | 0.65 |

60 | 59 | 1.84 | 0.53 | 0.54 |

80 | 79 | 2.93 | 0.48 | 0.36 |

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Brothers asked, what is the price of extruded board in 2008 to do a report need to trouble to tell the next thank you

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

Send your message to us

XPS Extruded Polystyrene Board - Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords