Welding Wires for Welding Steel Pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our premium welding wire is the ultimate tool for professionals who demand the very best in welding performance, reliability, and versatility. With its high-quality materials and excellent stability, this wire delivers outstanding results in even the most challenging applications. Elevate your welding capabilities to new heights with our premium welding wire.

Our welding wires play a crucial role in ensuring the quality and durability of welded joints. It is necessary components of various welding processes, each tailored to specific applications and materials.

High-Quality Core Material:

Our products crafted from premium-grade steel materials, our welding wires are designed to withstand high temperatures and maintain their strength during the welding process. This ensures a strong, reliable weld joint.

Versatile Applications:

Our welding wires are available in a variety of compositions and diameters to suit different metals, welding processes, and industry requirements.

Excellent Weld Quality:

The combination of high-quality materials and advanced manufacturing techniques results in exceptional weld quality, with minimal porosity, cracks, or other defects.

Our Regular Specifications:

1)WELDING ELECTORODES:

AWS:E6013,E6010,E6011,E7018

DIAMETER:2.0mm-5.0mm

LENGTH:300mm,350mm,400mm

2)WELDING WIRE--STANDARD

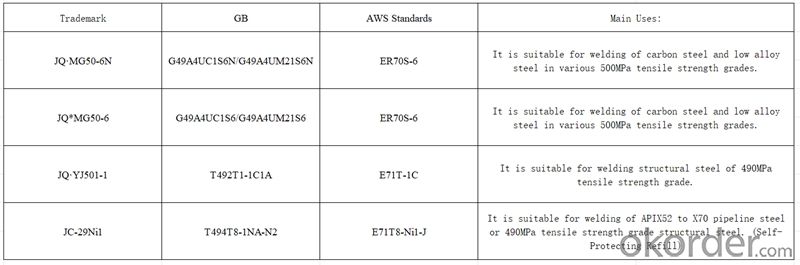

AWS:ER70S-6,E71T-1C,E71T8-Ni1-J

MIG WIRE AND FLUX CORED WELDING WIRE

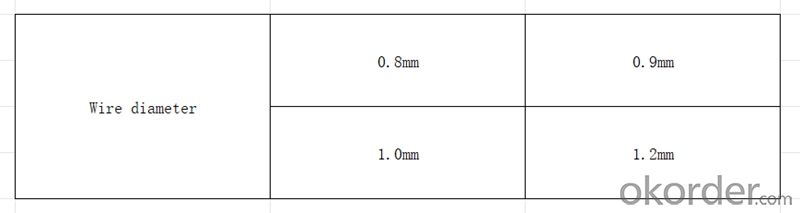

MIG WIRE ‘S DIAMETER: 0.8mm、0.9mm、1.0mm、1.2mm

15kg/D270;5KG/D200

FLUX CORED WELDING WIRE’S DIAMETER:1.0mm 1.2mm 1.6mm

15kg/D270, 5KG/D200

3)WELDING FLUX:

1.SURFACING FLUX -CORED WELDING WIRE

2.CARBON STEEL AND LOW-ALLOY STEEL SUBMERGED ARC WELDING WIRE

3.SINTERED FLUX

- Q: What wire is used for 316L stainless steel? Thanks

- Use the standards of the National Metallurgical Department, YB/T5092-2005:H03Cr19Ni12Mo2SiGBT 29713-2013 stainless steel wire and welding strip: S316LAmerican national standard, AWS, A5.9:ER316LJapanese standard: SUSY316L

- Q: 711 flux cored wire can weld 16 manganese steel plate, No.

- Yes, no problem. It can be welded! Q345's handle

- Q: Carbon steel, with two, welding current, voltage, welding speed, wire diameter, thank you

- The following welding parameters are usually used: 100-200A, 18-25V, 1.2-1.6mm

- Q: What kind of welding wire is used for 310S stainless steel plate?

- ER310, of course

- Q: How to test whether the flux cored wire is filled evenly?

- In the production process, many measurements can be carried out in an appropriate position, and the filling rate is monitored by weighing calculation, or an automatic control device for molding on-line monitoring filling rate is adopted.But there are few good ways for users to make accurate measurements (as judged by chemical analysis of deposited metals)

- Q: What is the difference between Q235B welding with H08mnA and H08A submerged arc welding wire? Which match is better? Ask professional personage to analyse for me

- H08mnA manganese content is higher, better performance. It is good for deoxidation and alloying of weldsHowever, the difference between the two is not big, the key depends on what you use welding flux to match

- Q: What is the relation between Jing Lei welding wire and Beijing group welding wire?

- Jing Lei is a trademark nameBeijing group is the name of the company.

- Q: Loose summer welding machine two, welding 0.8 wire current and voltage how to adjust?

- The welding parameters chungha Niho welding: welding wire diameter of 0.8 meters, voltage: 17V~19V, 90A~130A welding current and arc length 8 mm, gas flow rate 6L~12L minutes, left to the welding direction welding.According to the different welding parameters and welding position, according to the factors of parent material thickness, broken arc spot welding long weld welding specific selection of welding parameters.Panasonic two welding machine. No chungha Niho welding machine.

- Q: Argon arc welding how to continuously feed wire, the head of the welding wire will not sway.

- To straighten the wire, and then with the middle finger and index finger grip, by stretching two finger feeding wire

- Q: What is the difference between 321 wire welding and 304 wire welding?

- A thick difference of 0.3

Send your message to us

Welding Wires for Welding Steel Pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches