ER70S-6 Copper Coated Welding Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ER70S-6 Copper Coated Welding Wire

Material: copper coated carbon steel

Wire dia: 0.8/0.9/1.0/1.2/1.6mm

Packing: 15/20kgs/plastic spool/box, 72boxes/pallet

er70s-6 welding wire/ copper welding wire

1.Material:copper coated carbon steel

2.Wire diameter:0.8/0.9/1./1.2/1.6mm

3.Packing:15/20kgs/plastic spool/box, 72boxes/pallet.

4.Usage:

welding wire has excellent mechanical performance such as depositing speed and high efficiency, stable arc, little splash , good welding seam, strong resistance to surface scales and oil stains on the base metal, mainly used for welding low carbon alloy steel, industries of vehicles, bridge-engineering, machine-engineering, steel structures, shipping manufacture.

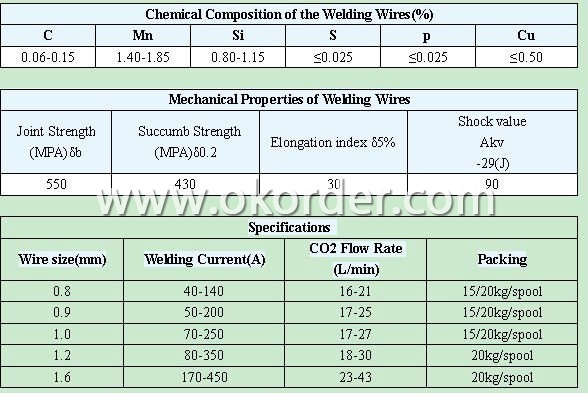

5.specification

- Q: Why is flux cored wire submerged arc welding?

- Relatively, the price of the submerged arc flux cored wire is lower, and it depends on what welder you choose. There are submerged arc welding machines and gas shielded welding machines. Therefore, there is submerged arc flux cored wire.

- Q: What wire is used for 316L stainless steel? Thanks

- With the corresponding AWS A5.9 ER316L American Standard stainless steel wire

- Q: I would like to register the trading company, agent wire, I would like to know in the industrial and commercial registration of wire and wire, what kind of business scope is belonging to?

- It is not necessary to write the welding material directly in the building materialSales of hardware, electrical, building materials, electronic products, machinery and equipment, rubber products, plastic products, chemical products (excluding dangerous chemicals), steel, instruments and meters, auto parts, stationery office supplies.

- Q: Which kind of welding wire is needed for the welding of No. 20 steel and 316L?

- A302, A312, A062, A042, A102, A402, etc. can be used (manual arc welding)Suggest A042 or A402.A402 high temperature 1150 degreesGFS-309MOL (GB/T17853, E309MOT1-1) for carbon dioxideGTS-309MOL for argon arc welding

- Q: What is the difference between Q235B welding with H08mnA and H08A submerged arc welding wire? Which match is better? Ask professional personage to analyse for me

- Nothing different.Better with H08A. It does not contain Mn

- Q: What kind of material is gas shielded welding wire?

- Well, you can say that

- Q: What does "GHS-70" wire mean?

- High strength steel wire, tensile strength 630MPa.

- Q: Can ER308 welding wire be replaced by ER321?

- Can ER308, the national brand is H08Cr21Ni10Si, ER321 national brand is H08Cr19Ni10Ti, ER321 and ER308 compared to Cr-Ni elements had little difference, just add ER321 stabilization element Ti can improve the intergranular corrosion resistance of weld

- Q: What core welding wire is used to weld 345C steel plate?

- Solid welding wire ER50-G, ER50-6, flux cored wire CHT701, CHT711 for Q345C steel plate,

- Q: Is the ER50-6 good solder wire?

- The correct welding line expression is: ER50-6, should meet the national standard GB|T8110 requirements, is a good welding wire.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;ISO 17799 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | XINGANG |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

ER70S-6 Copper Coated Welding Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords