Welding Electrodes for Welding Steel pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our welding electrodes products boasts a combination of durability, versatility, and ease of use that sets them apart in the industry.

It engineered to deliver exceptional performance, reliability, and versatility across a wide spectrum of welding applications. These electrodes are meticulously designed and rigorously tested to ensure they meet the highest industry standards, making them an ideal choice for professionals and enthusiasts alike.

High-Quality Core Material:

Our products crafted from premium-grade steel materials, our welding electrodes are designed to withstand high temperatures and maintain their strength during the welding process. This ensures a strong, reliable weld joint.

Versatile Applications:

Suitable for use in both AC and DC welding environments, our electrodes cater to a diverse range of welding tasks including mild steel, stainless steel, cast iron, and low-alloy steel welding. Enhancing your work's flexibility and efficiency.

Compliance & Safety:

All our welding electrodes comply with international safety standards and regulations, ensuring the safety of both welders and the environment during use.

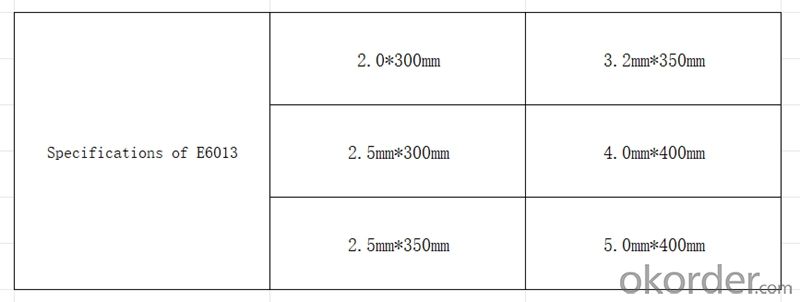

Our Regular Specifications:

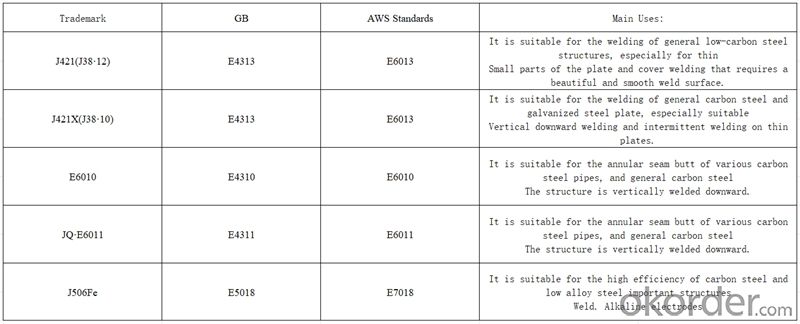

1)WELDING ELECTORODES:

AWS:E6013,E6010,E6011,E7018

DIAMETER:2.0mm-5.0mm

LENGTH:300mm,350mm,400mm

2)WELDING WIRE--STANDARD

AWS:ER70S-6,E71T-1C,E71T8-Ni1-J

MIG WIRE AND FLUX CORED WELDING WIRE

MIG WIRE ‘S DIAMETER: 0.8mm、0.9mm、1.0mm、1.2mm

15kg/D270;5KG/D200

FLUX CORED WELDING WIRE’S DIAMETER:1.0mm 1.2mm 1.6mm

15kg/D270, 5KG/D200

3)WELDING FLUX:

1.SURFACING FLUX -CORED WELDING WIRE

2.CARBON STEEL AND LOW-ALLOY STEEL SUBMERGED ARC WELDING WIRE

3.SINTERED FLUX

- Q: One millimeter thick iron direct current welding machine welding 3.2 electrode, need much current?

- 1, 3.2 electrode obviously thicker; should use less than 2.5 diameter of small welding rod;2 、 welding electrode and current matching empirical parametersWelding rod diameter 1.6, 2, 2.5, 3.2, 4, 5, 5.8Current (A) ranged from 25~4040 to 6050~80100 to 130160~210200 to 270260~300This is the experience of welding current, welding, horizontal welding, overhead welding welding current should be smaller than usual 10% ~ 20%.Exp is the confirmation at the time of the experiment. Therefore, before the formal welding, the welding sample should be taken, and the welding current should be obtained to get a solid and beautiful bead.

- Q: What type of welding machine does not use electrode welding machine?

- The welding machine without electrode is of the same type, that is, common standard welder.Because the welding machine interface size can be adjusted, you can use a variety of electrodes. Instead of an electrode with a welding machine.The electrode (covered electrode) is a strip of metal gas welding or welding when the filler metal in the joint welding of the workpiece. The electrode material is usually the same as the material of the workpiece.

- Q: H13 what kind of welding rod is used for steel welding?

- H13 is because the hot die die, as far as possible without welding, such as welding and molding after then try to use the stainless steel welding rod or wire, if you need to have the strength of welding, preheating in the best welding preheating temperature between 500-600 degrees is appropriate, the good after welding with some insulation material covering. Such as asbestos, the slow cooling speed, reduce welding stress.Avoid soldering prior to heat treatment.

- Q: When 507560 electrodes are used at the same time, which electrode should be selected?

- 507 506 welding preferred 506. No 560 electrodes, this specification, model, brand.Brand: J506, model: E5016 belongs to low hydrogen and potassium alloy structural steel welding rod. AC welder (no-load voltage is not lower than 70V, machine load rate of not less than 60% of rated output current, welding welding not less than 300 Amperes) DC welder (reverse connection wire clamp is connected with the cathode electrode holder is connected with the anode -, +) polarity electrode. Good welding process. Non Q345 class boilers, containers, pipes and other special components; first choice should be J506 welding rod.Brand: J507, model: E5015 belongs to low hydrogen sodium type low alloy structural steel welding rod. The electrode does not contain arc stabilizer. Only reverse polarity welding shall be used. Suitable for welding Q345R, container, steel and other precision parts. Compared with J506, the deposited metal has lower porosity, slag inclusion, crack and so on. It shall not be used without DC welder.

- Q: This question has been answered, but the answer is not consistent with the proposed problem, I want to ask is how long after the use of suitable electrode, can not damage the electrode holder, but also save, thank you!

- Current magnitude plus experience

- Q: Welding Q345C steel plate with ordinary electrode?

- Welding Q345C steel plate with ordinary welding rod, that is, 16Mn should use 507, ordinary welding rod welding performance is poor, hope to adopt

- Q: Is the electrode electrically conductive?

- Because there is wire electrode conductive, synthesis of various substances, covered up, welding machine output two AC machine is not divided into wire, welding wire, welding machine DC cathode to anode grounding wire, two output voltage will be encountered after the ignition, the electrode is electrically conductive. The electrode was encountered after the ignition, melting body, outside of the medicine is to protect the melted wire, prevent the pores, electrode head with no welding electrode holder, if the flux is not conductive to clip, also cannot be welded

- Q: Generally, how many packs are in one case and how many KG in one package?

- The electrode is 20 kg in a case.The electrode (coveredelectrode), is the metal coating in the welding core (coating), uniform centripetal pressure applied to core. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal.

- Q: What brand of carbon steel electrode is the best?

- Ordinary carbon steel electrodes are similar, the strength requirements are not very high, the welding rod does not have the best, all in line with national standards, but to see the welding technology is good.

- Q: Who knows what welding electrode is?

- Composition and function of welding electrode:One electrode. By core (metal core) and coating composition1. cores: metal cored electrode is coated with coating. Manual welding, welding electrode is not only.Filler metal.2. coating: pressure on the surface of the coating layer on the electrode. It is composed of a variety of ores, iron alloys, cellulose and binders.Two. Role of welding rodThe main function of the 1. cores:Act as an electrode to conduct current and to ignite an arc.Melt as filler metal and weld together with molten parent metal. In order to guarantee the quality of welding seam, the chemical composition of weld metal is more strict. Therefore, the core is specially smelting, low carbon and silicon content, sulfur and phosphorus content is extremely low.2., the main role of the drug skin:Mechanical protection: use the gas released from the melting of the crust and form the slag to isolate the air to prevent harmful gases from invading the molten metal.Metallurgical treatment: place harmful impurities (such as oxygen, hydrogen, sulfur and phosphorus) and add useful alloy elements, so that the welding seam can meet the required chemical composition and mechanical requirements.To improve welding performance: to make the arc combustion stable, less spatter, good weld formation, easy to remove slag, etc..

Send your message to us

Welding Electrodes for Welding Steel pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches