Welding Wire AWS 5.18 ER70S-6 Copper Coated High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Welding Wire Descrition

Applicable for single pass and multi-pass welding of carbon steel and 500 MPa grade low alloy steel and is widely used in such fields as automobile industry, construction machinery manufacturing, ship building, metallurgical and mining equipment manufacturing, bridge building, petrochemical industry and pressure vessel manufacturing, etc. Also applicable for high-speed welding of sheets and pipeline steel.

CO2 gas-shielded copper-plated welding wire has excellent welding technological property: the electric arc is stable with less spattering, the appearance of welded joint is nice with good crack resistance: it applies to all-position welding.

2.Main Features of Welding Wire

1. stable arc

2. low splashing

3. high deposited effeciency

4. beautiful seam

5. suitable for all position

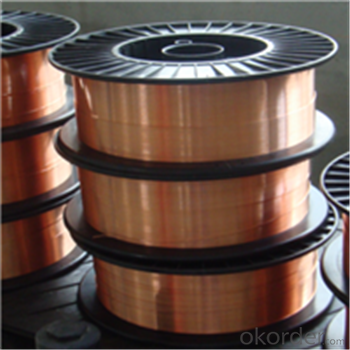

3.Welding Wire Images

4.Welding Wire Specification

ELEMENT | C | Mn | Si | P | S | Cu | |||||||||||

SPECIFICATION | 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.025 | ≤0.50 | |||||||||||

ACTUAL RESULT | 0.099 | 1.54 | 0.92 | 0.015 | 0.011 | 0.03 | |||||||||||

MECHNICAL PROPERTIES OF THE ALL-WELD-METAL | Shielding Gas or Flux | Radiographic Test | |||||||||||||||

ITEM | (Mpa) TENSILE | (Mpa) YIELD STRENGTH | (%)ELONGATION | TEST OF V MODLE IMPACT | |||||||||||||

IMPACT VALUE | TEST TEMP | ||||||||||||||||

SPECIPHICATION | ≥500 | ≥420 | ≥22 | ≥27J | -20°C | CO2 | Ⅱ | ||||||||||

ACTAUL RESULT | 542 | 437 | 29.3 | 79 83 81 | -20°C | CO2 | Ⅰ | ||||||||||

5.FAQ

Q:Are you factory?

A:Yes, we are factory not shell company. So we can promise good prices and best quality. Welcome you to visit our factory.

Q: What's the delivery time?

A: For products in stock, we can ship it within 7 days after receiving your payment. For custom order, within 24 tons, production time is 20-30 days after confirmed every details.

Q: What about the warranty?

A:Best price offer,On-time delivery,Strict quality control,The most comprehensive and the most attentive service

- Q: What kind of welding wire is used for 310S stainless steel plate?

- ER310, of course

- Q: What type of welding wire should be used for welding 304 austenitic stainless steel?

- Stainless steel flux cored wire E308LT1-1Stainless steel solid core welding wire ER308

- Q: 3003 what welding wire used for aluminum welding, I have tried ER4047, but the aluminum plate has melted, the welding wire has not melted, I used 4MM welding wire. And you said to me is not the aluminum welding wire or other reasons, I should use what types of aluminum wire

- Hello, ER4047 is used for carbon dioxide gas shielded welding wire, you said 3003 steel plate is aluminum manganese alloy, with aluminum manganese alloy welding wire, or aluminum silicon alloy welding wire HS311, HS321

- Q: Why is welding wire plated copper?

- The main purpose of copper wire welding is corrosion protection, because the main component of the wire is steel, and the bare leakage is easy to rust and corrosion in the atmosphere. The surface coating of copper can effectively prolong the shelf life. Furthermore, electrical conductivity can be enhanced.Welding wire is used as filler metal or metal wire welding material at the same time as conductive. In gas welding and gas tungsten arc welding, welding wire used as filler metal; in submerged arc welding, electroslag welding and MIG arc welding, welding wire as filler metal, and conductive electrode. The surface of the wire is not coated with anti oxidizing flux.

- Q: What is the relation between Jing Lei welding wire and Beijing group welding wire?

- One family. Beijing group is the name of the company, Jing Lei Shijing group company product trademarks.

- Q: The Atlantic Tiantai stainless steel wire and of which good?

- The answer to this question is very simple, no one else answer, let the two companies send samples, try to know the results.Our company will send samples first and then ship them.

- Q: What type of wire for automatic submerged arc welding of Q345B steel plate?

- HJ431+H08MnA, or SJ101 (301), +H10Mn2 and so on, are all possibleGenerally, the welding of sheet metal is made by HJ431+H08MnA, and SJ101 (301) +H10Mn2 is used as medium plateThe reason is that the trace elements in welding materials are different, resulting in some mechanical properties of weldability, forming and weldingDifference, of course, often welding, know why.The pH of welding flux is different to the appearance of weld and the sensitivity of crackGenerally speaking, SJ101+H10Mn2 is preferred in the process of welding. Now the general units are basically the welding mix

- Q: What's the recycling of the wire tray for?

- Can be sold to do welding wire factory, but the surface can not be tainted, that is, basically clean, so that the factory bought at low prices can also be used in the past, but also considered recycling.

- Q: What is the national standard for TIG welding of tungsten stainless steel?

- New standard YB/T5092-2005 this is

- Q: Normally, the proportion between submerged arc welding wire and flux should be answered

- 1:1 or so. The amount of filling welding is less, but the amount of cover welding is more. When the steel plate is no more than 9mm thick, the flux requirement is the same. If the production plan is reported, according to your total amount of work, the total length of the weld is greater, the results of the added proportion is smaller.

Send your message to us

Welding Wire AWS 5.18 ER70S-6 Copper Coated High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords