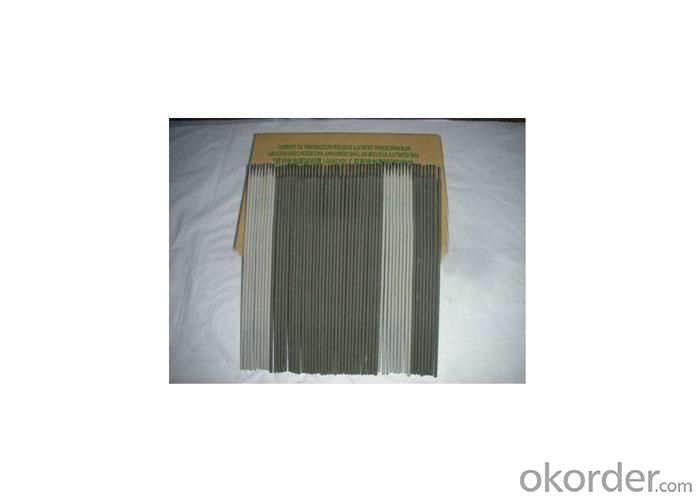

Factory Supply Mild Carbon Steel Welding Electrodes AWS E6013 High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1200 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

mild steel welding electrodes

It has excellent fabrication weldability,suitable for welding on thin plate of low-carbon steel

mild carbon steel welding electrodes AWS E6013 factory

It is a low carbon steel electrode with rutile type coating and suitable for both AC and DC.

The electrode is able to provide excellent welding technological performance because the arc is extra stable and spatter loss is negligible, the slag has good fluid and solidified slag is very easy to remove, the manipulate is free and restrike is easy.

It can give smooth and beautiful ripples.

Application: Used to weld low carbon steel structures, especially suitable for welding thin flat, intermittent shorter welds, as well as some smooth appearance cover.

CHEMICAL COMPOSITION OF MELTING METAL%

C | Mn | Si | S | P |

≤0.10 | 0.30.6 | ≤0.035 | ≤0.035 | ≤0.040 |

Reference Current

Diameter(mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | |

Current range(A) | Flat(A) | 40~60 | 60~90 | 90~130 | 140~190 | 190~240 |

Vertical&Overhead (A) | 30~55 | 50~80 | 80~120 | 120~170 | 150~200 | |

- Q: H0Cr20Ni10Ti H08Cr19Ni10Ti (ER321) to replace the standard YB/T5092-2005? Only H08Cr19Ni10Ti (ER321), it is not written to replace the one ah, whether there is a substitute for national notice? For the pressure vessel, to use H0Cr20Ni10Ti but the seller said this is a veteran, H08Cr19Ni10Ti (ER321) is a new grade, but can not find alternative basis?

- Strong, take a bubble

- Q: The design pressure is 27.5Mpa and the hydraulic test pressure is 41.25Mpa. Can the ER304 welding wire reach the strength requirement?In addition, what welding wire is used in the welding argon arc welding between 20# steel tubes? Given a better buy on the market, piping design pressure of 4.0Mpa.

- Just use the wire!!

- Q: 3003 what welding wire used for aluminum welding, I have tried ER4047, but the aluminum plate has melted, the welding wire has not melted, I used 4MM welding wire. And you said to me is not the aluminum welding wire or other reasons, I should use what types of aluminum wire

- It's not a wire problem. Is it argon arc welding or?

- Q: Can CO2 welding wire be used as argon arc welding wire?

- In GB/T14958 - 1994 "wire for gas shielded welding", there is no difference between its welding wire and argon arc welding wire.GB/T8110 - 1995 "for gas shielded welding of carbon steel and low alloy steel wire" standard for carbon steel and low alloy steel GMAW with solid core wire, recommended for tungsten inert gas welding and plasma arc welding filler metal.So: if you use different standards, the argon arc welding wire and the two wire are different in composition.Classification of steel wires:1, according to the use: carbon steel wire; low-alloy steel wire; stainless steel wire; hard alloy welding wire; copper and copper alloy wire; aluminum and cast iron welding wire Aluminum Alloy wire.2, according to the welding method for welding wire submerged arc welding; welding wire; welding wire for gas shielded welding; welding with electroslag welding.3. According to the cross section shape and structure of welding wire, it is divided into solid cored steel welding wire and flux welding wire.Carbon dioxide gas shielded welding is mainly used for welding low carbon steel and low alloy steelAlmost all metal materials can be welded by argon arc welding, but they are mainly used for welding non-ferrous metals and their alloys, stainless steels and some alloys.So, if your solder material is different, the selected wire is not the same in composition.

- Q: What kind of gas shielded welding wire for Q345 steel plate?

- er-49-1 ER50-6(GB / / t8110-2008)

- Q: What welding wire is used for welding 12Cr1MoV and 20G?

- Selection principle is generally: welding wire according to the low strength of steel selection, process measures according to the requirements of high steel. Therefore, H08A welding wire is selected.

- Q: Can gas shielded welding welding aluminum welding wire?

- You can put the wire into U, rotation gear, wire feeding hose for Chengtefurong, gun into the water. That's it.

- Q: Can the stainless steel welding wire for cast steel be welded?

- Not welding, that is, welding, and the effect is not good.

- Q: Base metal Q235, thickness 4-30mm, welding wire H08C, T type welding, argon rich gas shielded welding. What is the energy of welding line?

- The welding line energy depends on the welding current, welding voltage and welding speed. These are the main ones that you haven't written.The welding current is generally between 200-240 and the voltage is between 22-26, but there are some fine adjustments according to the plate thickness and the welding layer. The welding speed is different according to the size of the welding foot, the welding angle of the general A4 and the welding speed 250-300mm/min.Line energy, remember the formula yourself, 0.8*60*I (current A), *U (voltage V) / 1000V (welding speed mm), unit Kj/mm.

- Q: What core welding wire is used to weld 345C steel plate?

- Two ER50-6 for welding

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin port,Qingdao port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Russian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Factory Supply Mild Carbon Steel Welding Electrodes AWS E6013 High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1200 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords