Welded PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are other requirements for the installation of such fire prevention systems, such as that the fire service should be consulted and their advice on a suitable position for those systems to be installed taken. A dry riser system likewise must be situated near a water supply so that adequate flow can be obtained for fire fighting purposes.

However, those regulations for installing a dry riser system in commercial buildings in the UK are not all there is to it.

In addition to those requirements, the law states that dry riser systems also need to be maintained and serviced regularly. And this is where we’re getting to the subject of dry riser testing.

Obviously, dry riser testing must be performed by qualified and certified professionals. As a business owner, you will normally have a contract with a firm that conducts those tests on a regular basis.

Only when your dry riser system is tested and certified as operating properly it can grant you and your business the right amount of fire safety and protection.

Finding a firm that can do the necessary dry riser testing procedures

- Q: where to buy Transformer steel?Used in transformers and electric motors.

- Here okorder

- Q: What minerals are mixed to make steel?

- W - weldable steel WT- Weldable Noctch-tough steel R - Atomospheric corrosion-resistant steel A - Atomospheric corrosion-resistant steel weldable steel R - Atomospheric corrosion-resistant steel weldable Notch-tough steel Q- Quenched and tempered Low-alloy Steel QT-Quenched and tempered Low-alloy Steel Notch-tough steel For W and WT: C, Mn, P, S, Si, small quanties Cb,V,Al For R, A, AT: C, Mn, P, S, Si, Cr, Ni, Cu small quanties Cb,V,Al For Q: C, Mn, P, S, Si, Cr, Ni, Cu, and small amounts of boron See CSA G40.21 if you want more info

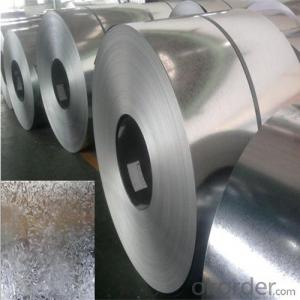

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q: what is the stucture of high carbon steel

- That is kind of a broad question because high carbon steel can cover a broad range and you did not mention the condition. But I will try to keep it simple. If it is in a wrought condition, it would likely be pearlite plus carbides along the grain boundaries., The atomic structure would be body centered cubic. Sometimes high carbon steel is spherodized annealed and that would be ferrite with lots of round carbides. The atomic structure would be body centered cubic. If it is quench and tempered, it would be martensite and would probably have noticeable carbides if the carbon content was high enough. The atomic structure would be body centered tetragonal

- Q: How are steel coils inspected for quality control?

- Steel coils are inspected for quality control through various methods. One common method is visual inspection, where trained professionals visually examine the coils for any surface defects, such as scratches, dents, or discoloration. Additionally, non-destructive testing techniques like ultrasonic testing are used to detect any internal defects, such as cracks or voids. Dimensional measurements are also taken to ensure the coils meet the required size and thickness specifications. These comprehensive inspections help ensure the overall quality and integrity of steel coils before they are used in various industries.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- 316L steel is the most basic metal used in body jewelry. It is the basic requirement of metal to be used in initial piercings and for healing. There are better grades but usually they cost more as well. For most people this grade of steel works just fine. Titanium is usually preferred over steel because it contains no nickel and it weighs almost 50% less than steel. Titanium can come in plain polish which looks just like steel AND it can come in a variety of colors (but NOT red or black). Titanium is super for people with sensitive skin to steel. It does cost a little more but is well worth it.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils are used in the production of electronic devices for various purposes, such as creating magnetic fields, providing structural support, and acting as conductors in transformers and inductors. These coils are typically wound around a core material, such as ferrite or laminated iron, to enhance their magnetic properties and improve their performance in electronic circuits.

- Q: What are the different methods of coil end welding for steel coils?

- There are several different methods of coil end welding for steel coils. These methods include: 1. Resistance Welding: This method involves applying an electric current to the ends of the coils, causing them to heat up and melt together. Resistance welding is commonly used for joining steel coils due to its high efficiency and speed. 2. Laser Welding: Laser welding utilizes a high-energy laser beam to melt and fuse the ends of the steel coils together. This method provides precise control over the welding process and can produce high-quality welds. 3. Tungsten Inert Gas (TIG) Welding: TIG welding uses a non-consumable tungsten electrode and an inert gas, such as argon, to create a protective atmosphere around the welding area. This method is known for producing clean and strong welds, making it suitable for steel coil end welding. 4. Plasma Arc Welding: Plasma arc welding involves using a plasma torch to create an electric arc between the electrode and the workpiece. The intense heat generated by the plasma arc melts the ends of the steel coils, allowing them to be welded together. 5. Electron Beam Welding: Electron beam welding utilizes a high-velocity beam of electrons to heat and melt the ends of the steel coils. This method is often used for joining thick steel coils and offers deep penetration and high welding speed. 6. Friction Stir Welding: Friction stir welding involves a rotating tool that generates friction and heat between the steel coil ends, causing them to soften and fuse together. This method is commonly used for joining aluminum coils but can also be applied to steel coils. These are just a few of the different methods of coil end welding for steel coils. The choice of method depends on various factors such as the desired weld quality, production speed, material thickness, and application requirements.

- Q: What are the major challenges faced by steel coil manufacturers?

- Some major challenges faced by steel coil manufacturers include fluctuations in raw material prices, increasing competition from international markets, the need to meet strict quality and safety standards, and the impact of global economic conditions on demand for steel products. Additionally, environmental regulations and sustainability concerns have also become important challenges for steel coil manufacturers.

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- steel case does not cause additional wear to the gun's chamber when compared to brass case. many tests has been done and precise measurements taken, this myth has been proven false. lacquer coating can cause issues because it can melt and cool, and cause jams. this is easily remedied with a chamber brush and some solvent.. However, steel jacket causes problems. Steel is harder than copper, it does not deform as easily so it causes more wear to the barrel as compared to copper or brass. The rate is around 10-25%, inreasing if you hoot rapidly instead of slowly. more shooting = hotter barrel = faster wear. It's the same with copper/brass jackets, but steel jacketed always wears more than softer metals. TulAmmo (or tula) is particular is so cheaply made they don't have enough copper/brass wash on the bullet to survive firing, after a few inches of travel it's steel on steel contact in the bore and it can ruin a gun barrel very quickly. But... there is one exception. if your gun comes with a chrome-lined bore that is standard for most AR's , shoot all the cheap junk you can buy. chrome-lined steel is 2X as hard as plain steel. crappy tula .223 will not cause more harm to a chrome-lined bore more than brass or copper jacketed bullets.

Send your message to us

Welded PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords