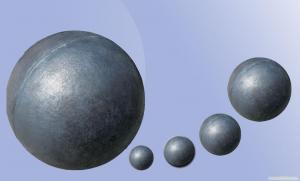

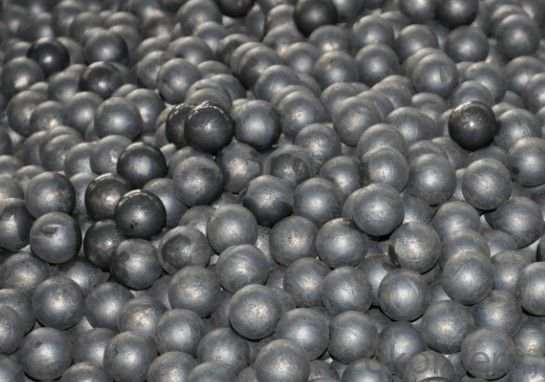

Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing and Cement Plan

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing

and Cement Plant:

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Applied Fields of Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for

Mineral Processing and Cement Plant:

1. Mines

2. Cement Plants

3. Chemical Industries

4. Power Plant

Type and Chemical Composition of Specifications of Forged and Casting Grinding Steel Ball with High Hardness

Made in China for Mineral Processing and Cement Plant:

Name

|

Material |

C |

Si |

Cr |

Mn |

S |

P |

CNBM-7 | Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -8 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -9 | Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -10 | Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |

CNBM -11 | Cr-5-10% | 2.1-3.2 | ≤1.2 | 5-10 | 0.5-1.5 | ≤0.06 | ≤0.08 |

CNBM -12 | Cr-1.5-3.% | 2.2-3.5 | ≤1.2 | 1.5-3.0 | 0.5-1.5 | ≤0.06 | ≤0.08 |

Physical Property of Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for

Mineral Processing and Cement Plant:

Name

|

Material

|

Impact Test Ak.J/cm |

Endurance Test times (5m) | Hardness (HRC) | |||

Diam25-60mm | Diam70-100mm | ||||||

Quenching | Unquenching | Quenching | Unquench ing | ||||

CNBM -7 | Cr-22-32% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 |

CNBM -8 | Cr-17-22% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 |

CNBM -9 | Cr-15-17% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥58 | ≥48 |

CNBM -10 | Cr-11-14% | ≥3 | ≥10000 | ≥58 | ≥49 | ≥56 | ≥48 |

CNBM -11 | Cr-5-10% | ≥3 | ≥8000 | - | ≥48 | - | ≥48 |

CNBM -12 | Cr-1.5-3.% | ≥2 | ≥8000 | - | ≥48 | - | ≥45 |

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

- Q: The difference between sheet metal and casting parts

- Commonly used in machine tools casting material is gray cast iron, casting bearing alloys can also be.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing and Cement Plan

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords