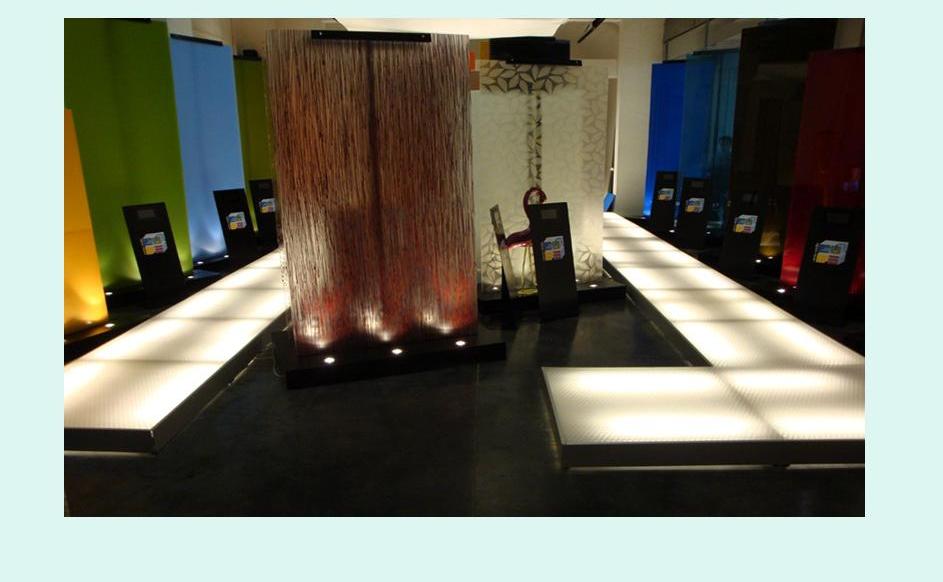

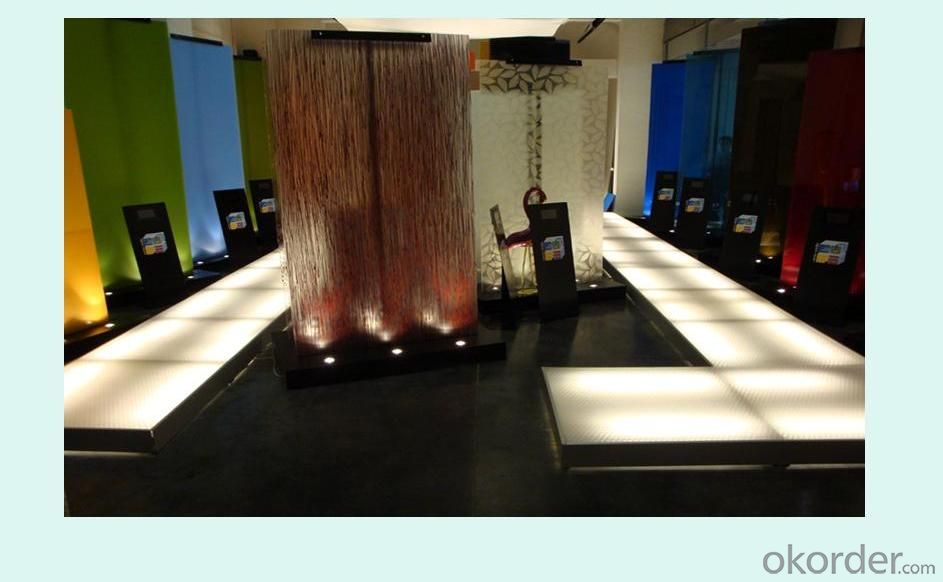

Water Drop Plastic Sheet Widely Used in Hotel and Shopping Mall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Water Drop Plastic Sheet Widely Used in Hotel and Shopping Mall

Features:

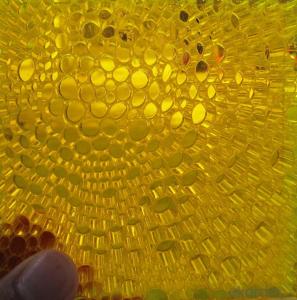

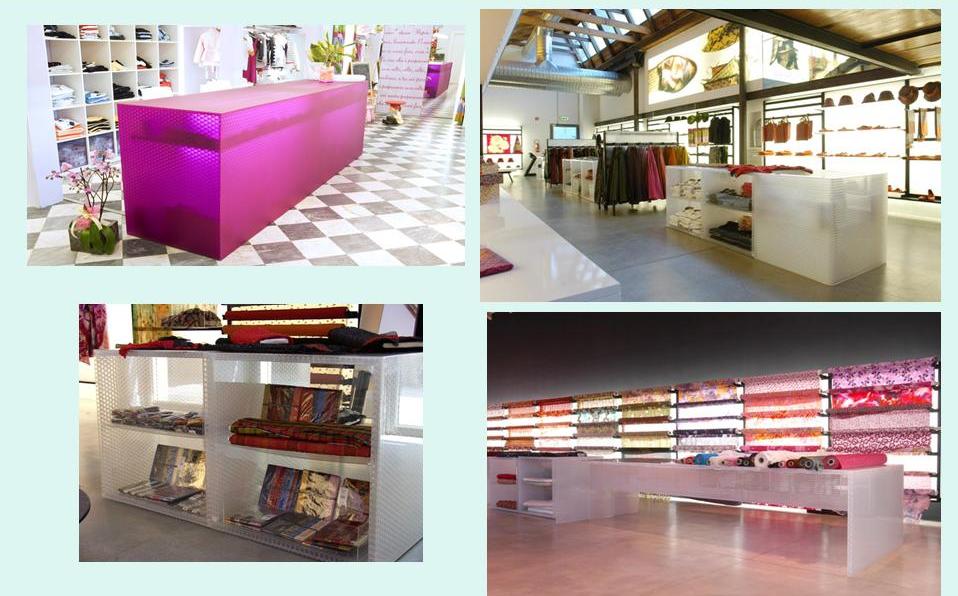

Light weight with high strength, heat & sound insulation, low deformation and yellowing, high shock resistance and compressive strength, environmental friendly and easy clean. It is widely used for partitions, floors, suspended ceilings, table-boards, light boxes etc. in hotel, business space, bar, specialty store, villa, entertainment venue and so on. It is also applicable for indoor and outdoor places. Delicate and transparent, strong sense of art, interspersed water droplets bring a sense of peace and ice-cool. Interspersed like water droplets, clear and transparent, takes on a kind of water drop reflection effect under LED light. It’s incomparable among modern decoration materials, and it’s absolutely required material for interior and exterior slap-up building

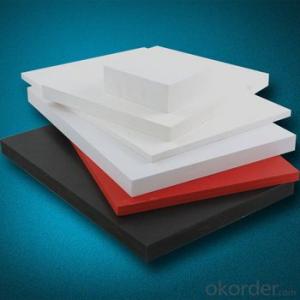

Specification:

Materials: PETG

Honeycomb core: PC

Tubular Diameter:4,6,8mm

Aluminium Length of Side: 3-18mm optional

Fire Rating:B1 or C

Temperature Tolerance:-40-80 ℃

Standard Size:1200*2400mm

Special Size: 1200*3000mm

Panel Thickness: 1 - 6mm

Gauge:6-50mm

Color: Customized colors

Finish: Glossy or Satin

Application:

FAQ:

1. What materials do you use for your product?

For honeycomb Panel, we use Polycarbonate, Acyrlic, PETG to produce outer up and down panel, use polycarbonate, Aluminum, Texture,plant and so on for Honeycomb Core or Interlayer

2. What if your payment term?

Generally, we accept L/C, TT, DA,DP payment term

3. Which port do you use and how long is your delivery time?

We are close to Shanghai Port and after receiving your down payment, we will arrange delivery within 25 days.

- Q: Are plastic sheets resistant to discoloration from humidity?

- No, plastic sheets are not completely resistant to discoloration from humidity.

- Q: Can plastic sheets be used for ceiling panels?

- Yes, plastic sheets can be used for ceiling panels. They are often chosen for their affordability, durability, and ease of installation. Additionally, plastic sheets offer various design options and are resistant to moisture, making them suitable for use in areas where traditional ceiling materials may not be ideal.

- Q: I am looking for something very thin and lightweight, but rigid. Not plexiglass. A little texture would be ok. I plan to paint it. I've seen the material I want in the little sample sheets that you can get with countertops, or siding or something. It is very thin - less than 1/16. Anyone know where I can get that in sheet form? thanks!

- Rigid Plastic Sheet

- Q: Are plastic sheets suitable for outdoor signage?

- Yes, plastic sheets are suitable for outdoor signage. They are weather-resistant, durable, and can withstand various environmental conditions such as rain, wind, and sunlight. Additionally, plastic sheets are lightweight, easy to install, and can be printed on or cut into various shapes, making them a popular choice for outdoor signage.

- Q: Are plastic sheets resistant to warping from cold temperatures?

- Yes, plastic sheets are generally resistant to warping from cold temperatures.

- Q: Are plastic sheets resistant to fading?

- Yes, plastic sheets are generally resistant to fading.

- Q: I'm quite tired of writing in a notebook and having the pages underneath hold the impression of what I wrote. I've seen these this plastic sheets that stop it but I'm not sure what they would be called. Any ideas?--Andriana

- Just take the underneath pages out...

- Q: What's glued to the plastic buckle?. Which glue does the wallpaper glue onto the plastic gusset plate?

- There is a wallpaper with pressure sensitive adhesive. When the protective paper is removed, it can be glued directly to the plastic gusset plate

- Q: Can plastic sheets be used for hygienic applications?

- Yes, plastic sheets can be used for hygienic applications. They are commonly used in healthcare settings, food industry, and cleanrooms to create barriers that prevent contamination and maintain cleanliness. Plastic sheets can be easily cleaned, are resistant to moisture and chemicals, and can be used as protective barriers for various hygienic purposes.

- Q: How do I find on the internet a plastic manufacturer that can glue two 1/4 thick sheets of acryllc together?

- The okorder These are my main suppliers but you may find others with a search for watch supplies.

Send your message to us

Water Drop Plastic Sheet Widely Used in Hotel and Shopping Mall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords