Z -Section Forming Machine

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Unit set

- Supply Capability:

- 100Set Per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Z -Section Forming Machine

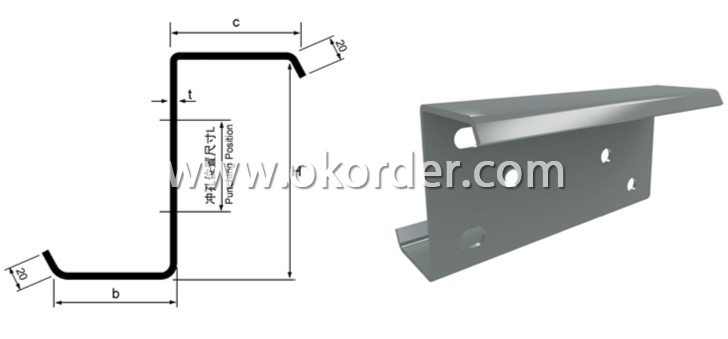

This machine is full-automatically controlled by PLC,the whole hydrau-lic transmission,drive hydraulic oil jar carry out and shear through centre pump station towarde the hole,hydraulic pressure motor trans-mit power as main transmission,characteristics. It is reliable to oper-ate steadily by hydraullc prdssure,Shear towards hole precision high,high output,low energy consumption,Section geometry form rule of the notch,Its hydraulic pressure trausmission ,two sets of rectification correct and fit,the cut-off have a national patent.

We can produce according to your drawing.

Main Technical Parameter of Z -Section Forming Machine

Number | Item | Specification | Unit/Type |

1 | Main roll forming machine model | Z |

|

2 | Rack structure | wall plate structure or column structure |

|

3 | Raw material | galvanized steel or color-coated plate |

|

4 | Original width | / | mm |

5 | Cover width | / | mm |

6 | Thickness of panel |

1.5-3.0mm | mm |

7 | Yield strength | 250 | Mpa |

8 | Forming speed | 0-15 | m/min |

9 | Main Motor Power | 30KW | KW |

10 | Roller material | 45# forged steel, polished and surface coated with Chrome |

|

11 | Main shaft material | 45# fine steel, Quenching and Tempering heat treatment |

|

12 | Roll Stand | 16 | mm |

13 | Spec | 140-300 |

|

14 |

Waist Height: |

50-90mm |

|

15 | Hydraulic pressure | 12 | Mpa |

16 | Power supply | depend on customer's requirement |

|

17 | Cutter material | Cr12 |

|

18 | Electrical control system | Panasonic PLC |

|

19 | Cutting method | hydraulic cutting, automatically cut to length after roll forming |

|

20 | Color of the machine | depend on customer |

|

21 | Container needed | 1x40 | GP |

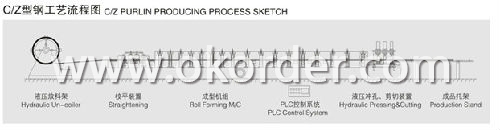

Producing Process Sketch of Z -Section Forming Machine

Application of Z -Section Forming Machine

Packaging & Delivery of Z -Section Forming Machine

Packaging Detail: | 1*40GP CONTAINER |

Delivery Detail: | 30 days |

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- Yes, the width of the bearing plate can be a deviation from the length.

- Q: What is rolling forming processing?

- A special rolling tool is used to exert certain pressure on the surface of the workpiece so as to make the surface metal flow.

- Q: Improvement in rolling forming process

- Rigid force, 1000N-3000N, damage to the guide rail of machine tool transmission mechanism, seriously damage the accuracy and life of machine tools.

- Q: Introduction of roll forming process

- Roll forming began around 1960s in europe. Because of roll forming, the working model has the advantages of high production efficiency, saving material and increasing product strength.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Non bonding wear of rolled material (especially stainless steel strip, etc.)

- Q: What is the surface rolling forming machine process?

- The rolling process using metal at room temperature, cold plastic characteristic, through the rolling tool is the rolling tool to put some pressure on the metal surface, so that the workpiece surface by plastic deformation, the height to the lower tissue slip, the surface roughness decreased.

- Q: Process mould for rolling forming process

- Press forming is an advanced processing technology, and its remarkable characteristics have been paid attention to by the automobile industry at home and abroad.

- Q: Material and equipment for roll forming process

- Rolling molding is usually through upsetting a blank cold heading machine, thread rolling machine rolling after processed. The equipment for thread rolling and rolling forming includes various reciprocating flat rolling machines, planetary wire rolling machines, two cylindrical roller spinning machines and three cylindrical roller spinning machines.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Z -Section Forming Machine

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Unit set

- Supply Capability:

- 100Set Per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords