Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester/Polypropylene Short Nonwoven Geotextile:

Short nonwoven geotextile made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commenly used to separate layers like clay and drainage and to protect liner from damage.

Main Features of Polyester/Polypropylene Short Nonwoven Geotextile:

1.Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction.

2.Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

3.Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

4.Excellent uniformity with high permeability and low pore size for soil filtration.

5.Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

6.100% polypropylene or polyester staple fibers ,needle punched and random network formation.

7.UV and rot resistant and biological degradation resistant.

Specifications of Polyester/Polypropylene Short Nonwoven Geotextile:

Item | Index | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Breaking strength at warp direction (kN/m) ≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking strength at weft direction (kN/m) ≥ | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation at break (%) ≤ | 28 | ||||||

Trapezoid tearing strength( warp direction ) (kN) ≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Bursting strength (kN) ≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical permeability coefficient (cm/s) | 10-1~10-4 | ||||||

Effective pore size O95,mm | 0.08~0.5 | ||||||

Mass per unit area (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Mass error in unit area (%) | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

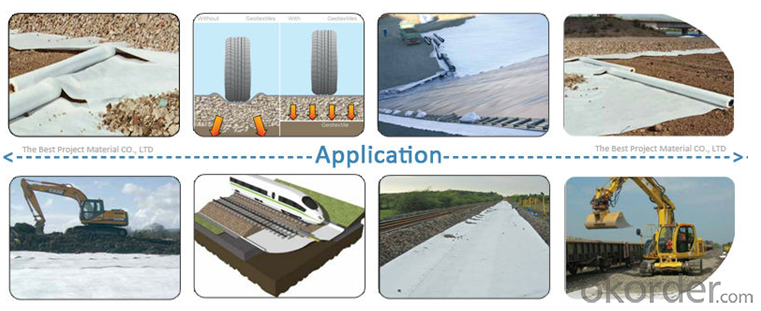

Applications of Polyester/Polypropylene Short Nonwoven Geotextile:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

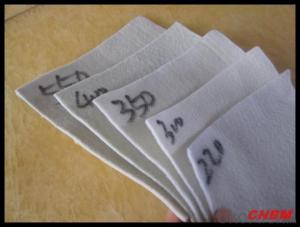

IMages of Polyester/Polypropylene Short Nonwoven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q: Can geotextiles be used for reinforcement of slope toe protection systems?

- Yes, geotextiles can be used for the reinforcement of slope toe protection systems. Geotextiles are commonly used in slope stabilization applications to enhance soil strength, increase resistance to erosion, and provide long-term stability to the slope. They can be installed at the toe of the slope to prevent soil erosion, improve drainage, and provide additional support to the slope.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: Is the polyester nonwoven fabric geotextile?

- Not geotextile. Polyester non-woven fabrics: mainly used for construction, roof waterproof as a base cloth, attached to the above sand, cement, etc., to prevent the role of sand leakage. Nonwovens are often used in construction and are a measure to prevent cracks. Geotextile manufacturers, for your answer

- Q: How are geotextiles maintained?

- Geotextiles are typically low-maintenance materials that require minimal upkeep. However, to ensure their longevity and effectiveness, geotextiles should be regularly inspected for any signs of damage or degradation caused by environmental factors or heavy loads. If any issues are identified, appropriate repairs or replacements should be carried out promptly. Additionally, periodic cleaning may be necessary to remove any accumulated debris that could potentially hinder the geotextile's performance. Overall, proper maintenance of geotextiles involves routine inspection, timely repairs, and occasional cleaning to preserve their functionality and lifespan.

- Q: How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by providing reinforcement, separation, filtration, and drainage functions. They help in preventing the mixing of different layers of pavement materials, which reduces deformations and extends the lifespan of the pavement. Additionally, geotextiles improve the load-bearing capacity of the pavement by distributing the load more evenly, reducing the likelihood of cracks or failures. They also aid in filtering out fine particles, preventing clogging and maintaining proper drainage, which further enhances the pavement's durability and resistance to water damage.

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been proven to provide effective soil stabilization, erosion control, and reinforcement in areas prone to seismic activity. They can help mitigate soil liquefaction, slope instability, and ground settlement issues, making them a suitable choice for construction projects in seismic zones.

- Q: What is the latest price of geotextile?

- Ask the geotextile price is too general, because the standard too much. Short wire, filament, polyester; non-standard, GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton.

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. Geotextiles provide various benefits such as soil stabilization, erosion control, filtration, and drainage, making them suitable for use in underground applications like tunnels, retaining walls, and underground drainage systems. They help improve the overall performance and longevity of the underground structures.

- Q: Can geotextiles be used in the protection of underground cables and pipes?

- Yes, geotextiles can be used in the protection of underground cables and pipes. Geotextiles act as a barrier, preventing soil particles and fines from infiltrating the cables or pipes, thus reducing the risk of damage or blockage. Additionally, they provide support and reinforcement to the surrounding soil, minimizing the potential for settlement or shifting that could affect the underground infrastructure.

Send your message to us

Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords