Venta De Geomembrana Resistancia Negra HDPE Para Forro De Estanque Con Precio Asequible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

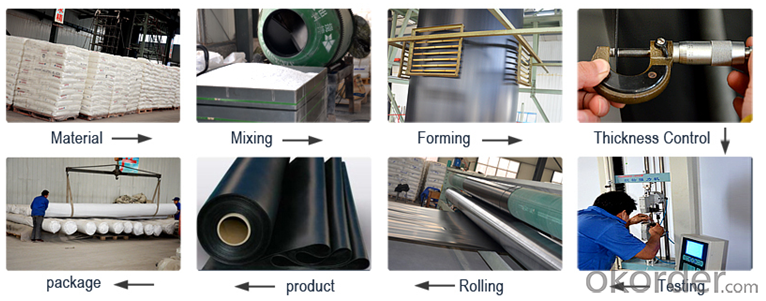

Description Of Resistance Black HDPE Geomembrane for Pond Liner:

Our high density polyethylene (HDPE) geomembranes provide an impermeable barrier against a wide range

of solids and liquids. They exhibit excellent chemical and UV resistance, impermeability, and high yield and

welded seam strengths, which is widely used as the liner.

Main Features of Resistance Black HDPE Geomembrane for Pond Liner:

1.Long life, anti-aging, roof material can be more than 20 years, underground can be more than 50 years.

2. Good tensile strength, high elongation.

3. Good high/low temperature flexibility

4.Easy to construct, no pollution.

5. Good anti-corrosive ability, can be used in special area

6.Various colors are available

Specifications of Resistance Black HDPE Geomembrane for Pond Liner:

a) Density ≥ 0.94g/m²

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

f.) Permeability Coefficient ≤1.0xe-13g.cm/(cm2.S.Pa)

g.) -70oC Low Temperature Impact Brittle Property: good.

h.) Chemical Resistance: at 80oC, marinated in 5g/L Nacl for a long time, it will not erode or swell.

Applications of Resistance Black HDPE Geomembrane for Pond Liner:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

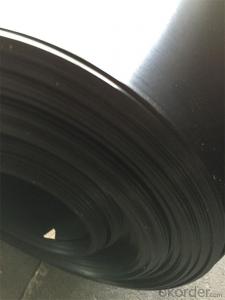

IMages of Resistance Black HDPE Geomembrane for Pond Liner:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the expected lifespan of a geomembrane?

- The expected lifespan of a geomembrane can vary depending on various factors such as the quality of the material, installation techniques, environmental conditions, and maintenance practices. However, on average, a well-designed and properly installed geomembrane can have a lifespan ranging from 20 to 30 years.

- Q: Who knows the repair method of membrane switch?

- Maintenance method of membrane switch: Just replace the membrane switch panel of the same model and specification. When replacing the membrane switch, you just need to detach its control plate, which can be done as long as you have basic practical ability (but if you don't have the ability, there is no way to do so). If you can't buy the membrane switch panel, you can replace it with a micro-switch. The circuit wiring should be in accordance with the old membrane switch panel, and the panel needs drilling, installing the micro-switch, fixing with silica gel and wiring.

- Q: How do geomembranes improve water efficiency in golf course irrigation?

- Geomembranes improve water efficiency in golf course irrigation by acting as a barrier to prevent water seepage and loss. They effectively contain and retain water within the irrigation system, ensuring that the water reaches the desired areas and is not wasted through leakage or evaporation. This helps golf courses optimize water usage, minimize water runoff, and reduce the overall water consumption, resulting in improved water efficiency.

- Q: How are geomembranes tested for durability?

- Geomembranes are tested for durability through a series of rigorous tests that assess their resistance to various environmental factors. These tests include measuring their tensile strength, puncture resistance, UV stability, chemical resistance, and dimensional stability. Additionally, accelerated aging tests are conducted to simulate long-term exposure to harsh conditions. By subjecting geomembranes to these tests, their durability and ability to withstand different conditions can be accurately evaluated.

- Q: How are geomembranes tested for quality?

- Geomembranes are tested for quality through a series of rigorous tests and inspections. These tests usually include tests for physical properties like thickness, tensile strength, tear resistance, and puncture resistance. Additionally, they are subjected to chemical resistance tests to ensure their durability and resistance to various substances. Furthermore, geomembranes are examined for seam strength, weld integrity, and dimensional stability. These comprehensive quality tests help ensure that geomembranes meet the required standards and are fit for their intended applications.

- Q: Can all-purpose adhesive stick composite geomembrane?

- The best way to stick composite geomembrane is to weld with sweat soldering machine or monorail welding gun. If there is no such device on the construction site, you can brush PE adhesive, or use all-purpose adhesive. Brushing must be uniform, and sticking should be close and tight. Brushing surface must be kept clean without water or mud. Brushing all-purpose adhesive is relatively expensive.

- Q: What are the benefits of using geomembranes in recreational water bodies?

- There are several benefits of using geomembranes in recreational water bodies. Firstly, geomembranes act as a barrier, preventing the seepage of water into the ground and reducing the risk of contamination from pollutants or chemicals. This helps in maintaining the water quality and ensuring a safe and healthy environment for recreational activities. Secondly, geomembranes minimize the loss of water by reducing evaporation and seepage, thereby conserving the water resources and improving the sustainability of the water body. Additionally, these membranes can provide a smooth and even surface, enhancing the aesthetics and comfort for activities such as swimming or boating. Lastly, geomembranes can also help control the growth of unwanted vegetation or invasive species, leading to easier maintenance and management of the recreational water bodies.

- Q: Are geomembranes resistant to fungal growth?

- Yes, geomembranes are generally resistant to fungal growth. They are designed to be impermeable to water and other liquids, which creates an unfavorable environment for fungal growth. Additionally, many geomembranes are made from materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC) that are inherently resistant to fungal growth. However, it is important to note that proper installation and maintenance are crucial to ensuring long-term resistance to fungal growth.

- Q: Can seepage-proof geomembrane be used to do home decoration?

- No

- Q: what's the standard that geomembrane welding point's breaking strength should reach?

- welding point strength is executed by GB/T16989 standard, the products standard of composite geo-membrane is GB/T17642-2008 .

Send your message to us

Venta De Geomembrana Resistancia Negra HDPE Para Forro De Estanque Con Precio Asequible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords